Microorganisms agent active protecting agent used for microorganism oil extraction of high-salinity oil well

A technology of microbial oil recovery and active protective agent, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as failure to produce good oil and environmental pollution, and achieve improved recovery costs, considerable economic benefits, and improved recovery Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

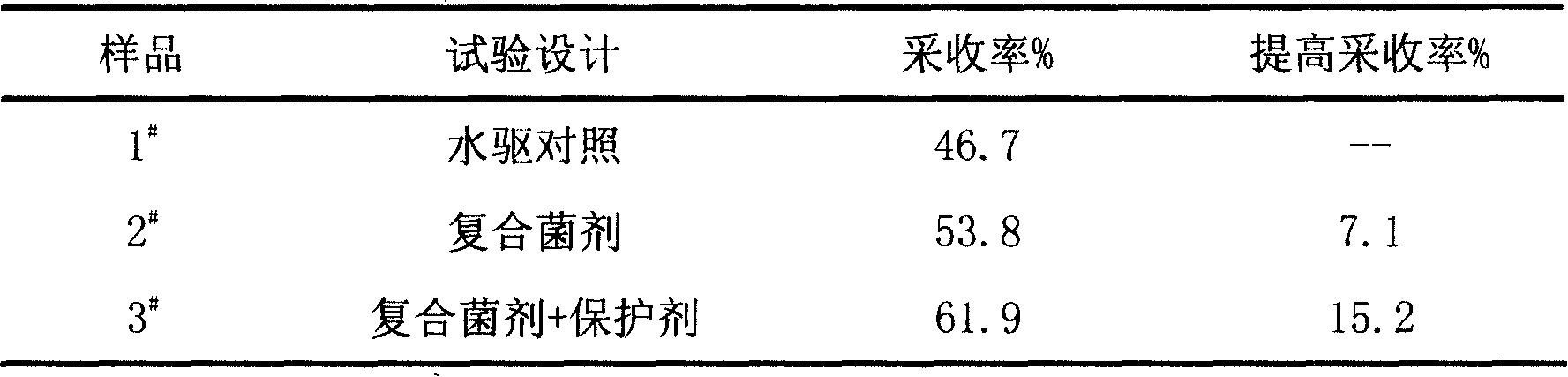

[0015] Example 1: Core simulated oil displacement experiment.

[0016] The microbial agent used in the test is a mixed agent: Pseudomonas (Pseudomonas.) N5, Bacillus (Bacillus.) Y4, Corynebacterium (Corynebacterium.) B7, and the volume mixing ratio is 3:3:2. The concentration of the compound bacterial agent is 10 7 ~10 9 pcs / ml, pH 5.5~6.5

[0017] KCl 1 g, NaCl 1 g, MgSO 4 0.06 g, MnSO 4 0.05 g is mixed and dissolved to form a mixed solution of inorganic salts, and mixed with 100 ml of compound microbial agent to form a mixed solution.

[0018] The specific operation steps are as follows:

[0019] 1. Prepare three stainless steel tubes with an inner diameter of 2.5cm and a length of 40cm, fill them with core sand of different meshes, seal both ends, and leave a tubular outlet.

[0020] 2. The permeability is 0.292~0.307μm 3 , vacuumize and saturate the formation water, the measured porosity is 35.7-37.3%, and the bound water is established through oil flooding, the o...

example 2

[0026] Example 2. Single well huff and puff field test

[0027] A low-yield oil well in Liaohe Oilfield was selected as an experimental oil well, and the throughput conditions are as follows:

[0028] 1. Well number for throughput operation: Well H14-35 in Haiwaihe Oilfield.

[0029] 2. Basic conditions of the operating well:

[0030] Basic data:

[0031] Production date

1996.01

Drilling depth

1800.0m

Artificial bottom

1791.54m

Completion method

Perforation

Casing specification

177.8mm

the depth

1798.80m

Cementing quality

qualified

Oil make-up distance

4.11

Set padding

4.43

Perforation thickness

17.8m

5

d 1

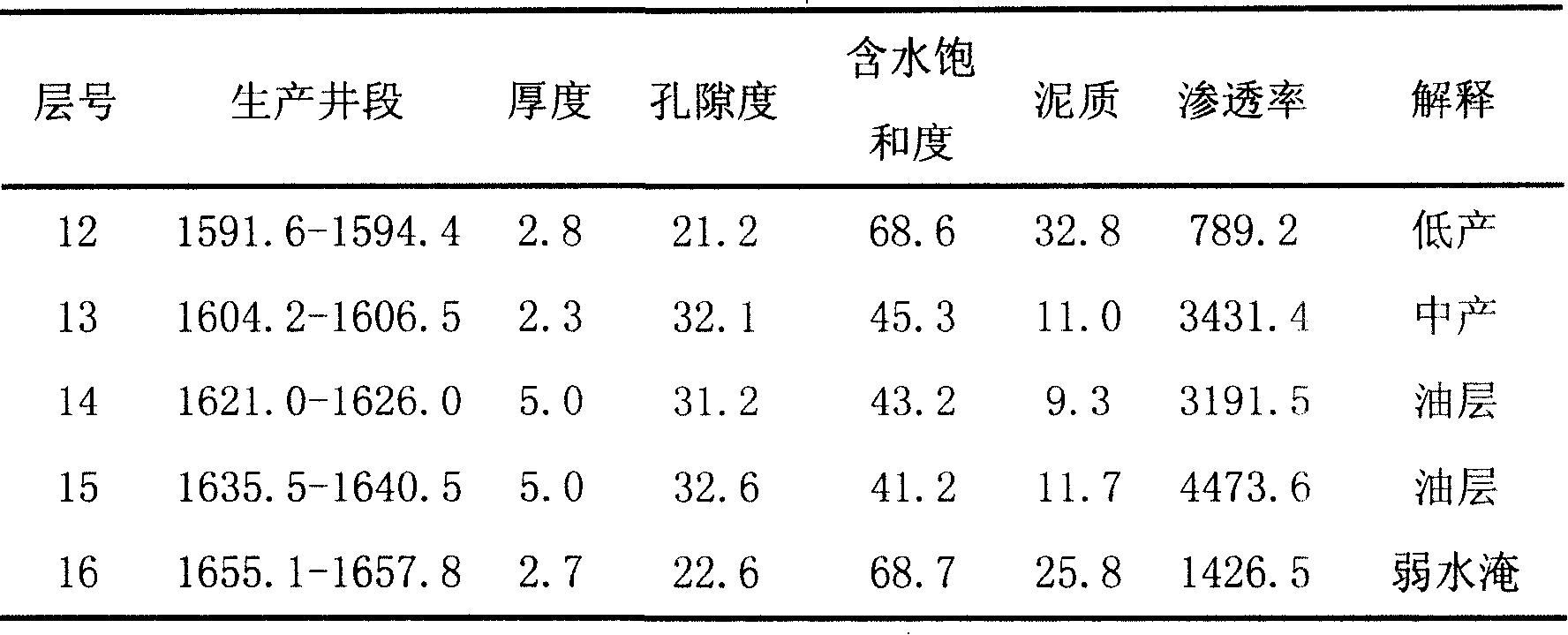

[0032] Interpretation of logging results:

[0033]

[0034] Production overview

[0035] Well H14-35 was put into production in January 1996, and the current production interval is 1591.6-1657.8m. The well is a low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com