Method for synthesizing low silica-alumina ratio beta zeolite

A technology with a low silicon-aluminum ratio and a synthetic method, which is applied in the field of synthesis of zeolite beta, can solve problems such as unseen synthesis, and achieve the effects of improving activity and activity stability, reducing diffusion resistance, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 125ml of sodium metaaluminate solution (sodium oxide 139.5g / L, aluminum oxide 100.0g / L) and tetraethylammonium hydroxide (2.03N, Daxing Xingfu Fine Chemical Research Institute) 340ml into deionized water, stir well, Make a working solution, mix zeolite beta 500g in Comparative Example 1 with the above-mentioned working solution, make the surface of the solid particle wetted by the working solution, and obtain a reaction mixture, wherein the molar ratio of each component in the synthesis system SiO 2 / Al 2 o 3 =15,Na 2O / SiO 2 =0.06, TEAOH / SiO 2 =0.09,H 2 O / SiO 2 =6.5, then the reaction mixture was crystallized in a high-pressure reactor at 150° C. for 24 hours, and the solid product was separated after cooling to room temperature, washed and dried.

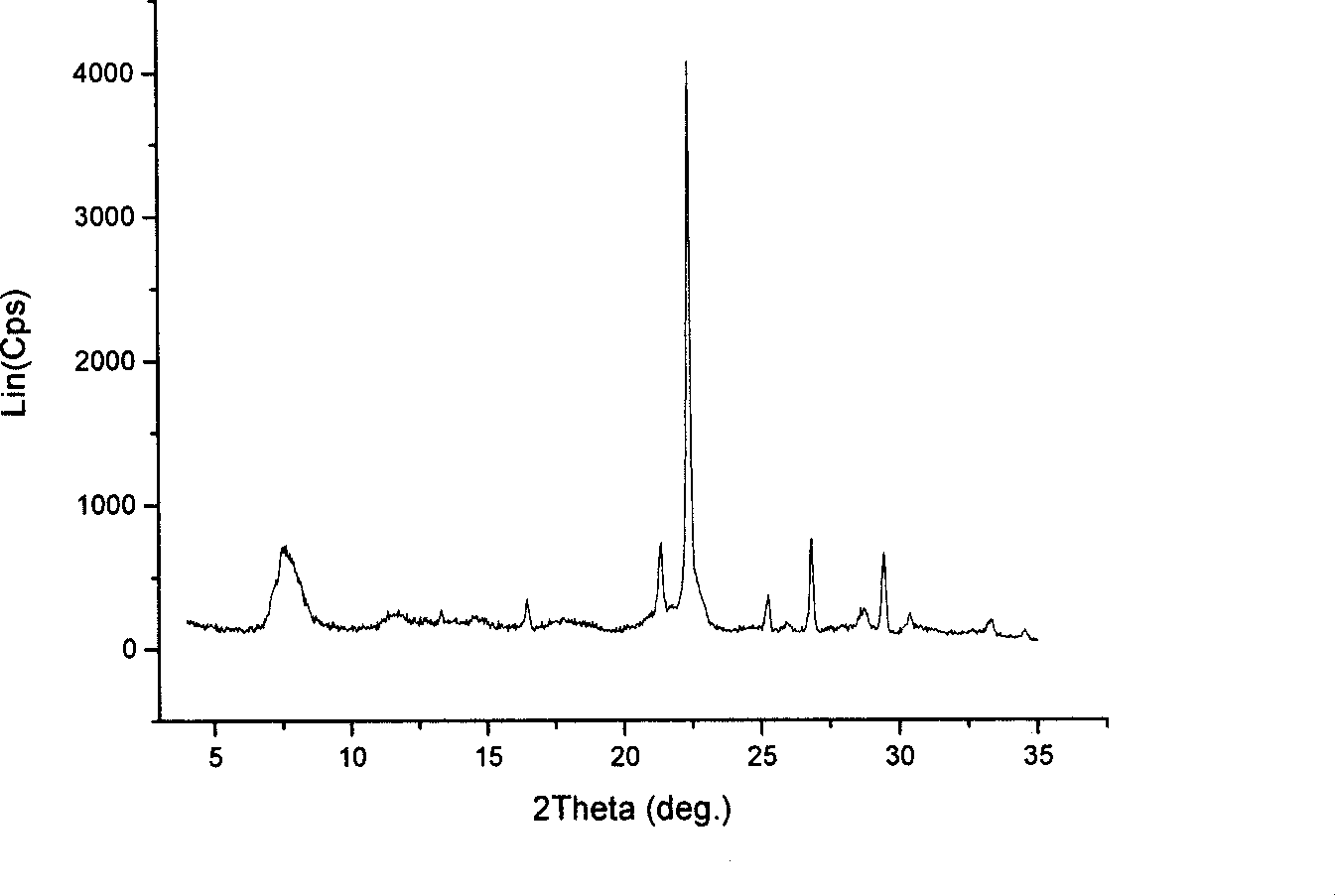

[0034] XRD crystal phase diagram as image 3 As shown, the relative crystallinity is 109.5%. Figure 10 for 27 Al MAS NMR spectrogram, this spectrogram result shows, this product has no non-skeleton aluminum, ...

Embodiment 2

[0037] Add 262ml of sodium metaaluminate solution (sodium oxide 139.5g / L, aluminum oxide 100.0g / L) and tetraethylammonium hydroxide (2.03N, Daxing Xingfu Institute of Fine Chemical Industry) 340ml into deionized water, stir well, Make a working solution, mix zeolite beta 500g in Comparative Example 1 with the above-mentioned working solution, make the surface of the solid particle wetted by the working solution, and obtain a reaction mixture, wherein the molar ratio of each component in the synthesis system SiO 2 / Al 2 o 3 =10, Na 2 O / SiO 2 =0.06, TEAOH / SiO 2 =0.09,H 2 O / SiO 2 =6.5, then the reaction mixture was crystallized in a high-pressure reactor at 150° C. for 24 hours, and the solid product was separated after cooling to room temperature, washed and dried.

[0038] Its XRD such as image 3 As shown, the relative crystallinity is 95.4%. 29 Si MAS NMR determined that its skeleton silicon aluminum ratio was 8.62.

Embodiment 3-8

[0040] Add sodium metaaluminate solution and tetraethylammonium hydroxide into deionized water, stir evenly to make a working solution, mix the β zeolite in Comparative Example 1 with the above working solution, and make the surface of the solid particles moistened by the working solution wet to obtain a reaction mixture, and then transferred to a crystallization tank for crystallization. The raw material composition, crystallization conditions and results are shown in Table 1.

[0041] Table 1

[0042] serial number

[0043] The result shows that the present invention provides the zeolite beta synthesized by the method, and the silicon-aluminum ratio of the sample is close to the feed ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com