Valve gear of engine

A transmission device and engine technology, applied in the direction of engine lubrication, valve driving device, engine components, etc., can solve the problems that hinder the miniaturization of the engine and reduce the cost, and achieve good maintainability, simplified structure and miniaturization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

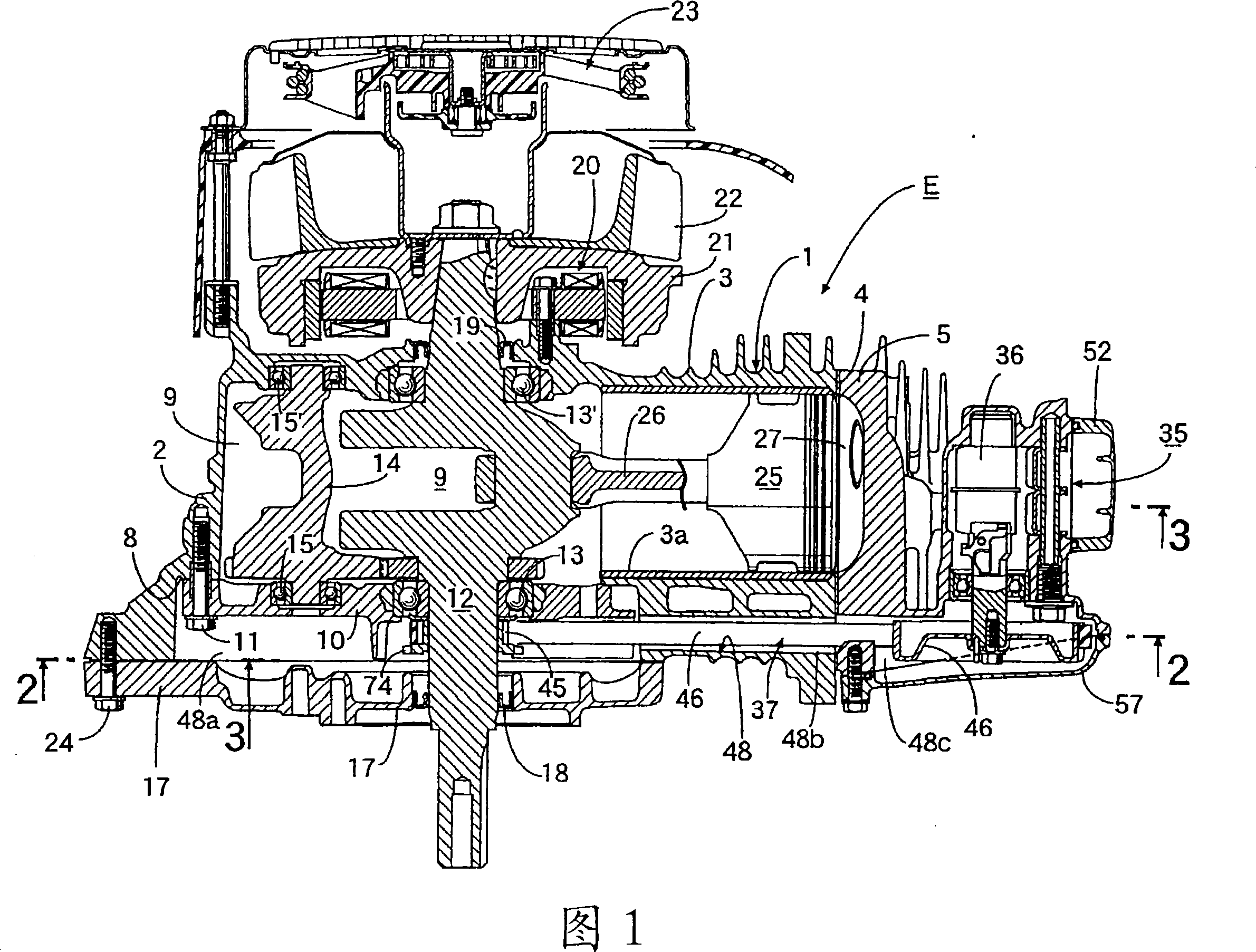

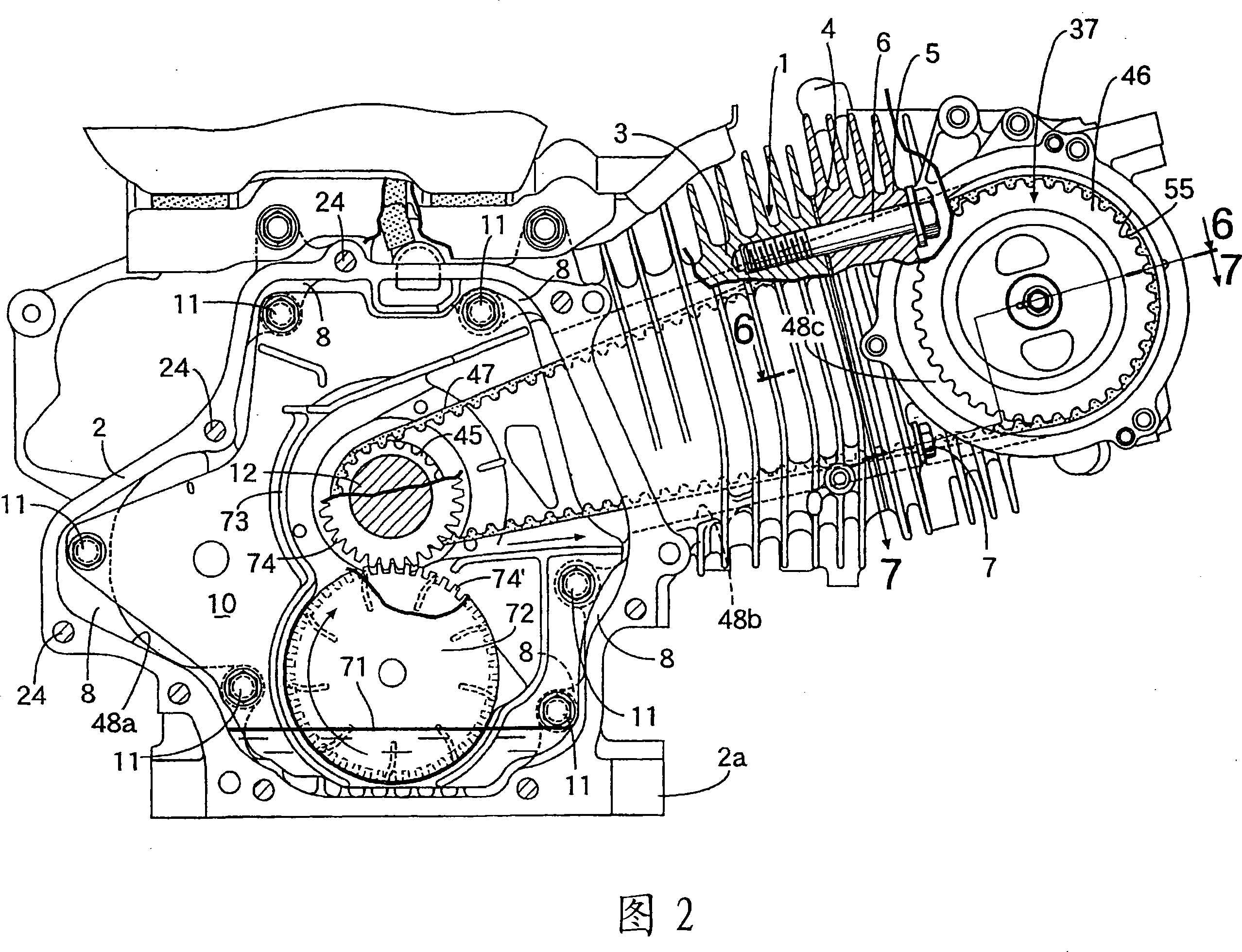

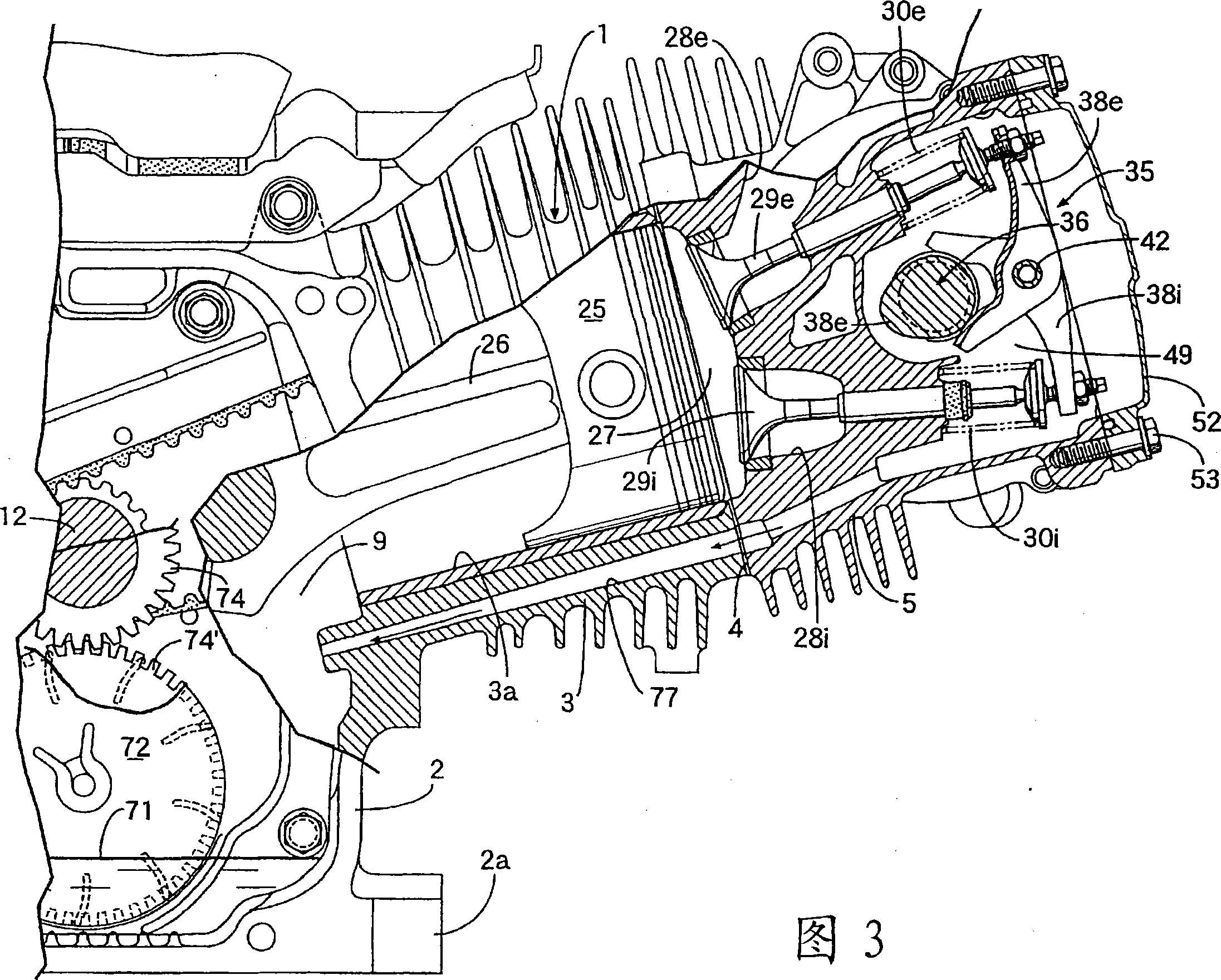

[0060] First, in FIGS. 1 to 4, the components of the engine body 1 of the general four-stroke engine E include: a crankcase 2 having a mounting seat 2a at the lower part; and a cylinder bore that is integrally connected with the crankcase 2 and has an upwardly inclined cylinder bore The cylinder block 3 of 3a; the cylinder head 5 joined to the upper end surface of the cylinder block 3 with the gasket 4 interposed between the cylinder head 5 and the cylinder block 3 is used in four positions around the cylinder bore 3a. The four main connecting bolts 6, 6... and the two auxiliary connecting bolts 7, 7 described later.

[0061]The crankcase 2 has one side open, and on the inner peripheral wall slightly inside from the open surface, a plurality of stepped portions 8, 8... which are arranged in the circumferential direction toward the open surface side are integrally formed, and these stepped portions 8 , 8... The bearing bracket 10 is fixed by a plurality of bolts 11, 11... Both ends...

no. 2 example

[0103] Next, another embodiment of the present invention shown in FIG. 13 will be described.

[0104] For this embodiment, a check valve 79 is provided in the oil passage 75 that communicates between the timing transmission chamber 48 and the valve transmission chamber 49. The check valve 79 only allows the passage from the valve transmission chamber 49 to the timing transmission chamber. 48 transfer negative pressure. The other structure is the same as that of the above-mentioned embodiment, so the parts in FIG. 13 corresponding to the above-mentioned embodiment are assigned the same reference numerals, and their description is omitted.

[0105] In this embodiment, when the pulsating pressure generated in the crank chamber 9 is transmitted to the valve transmission chamber 49, only the negative pressure therein acts on the timing transmission chamber 48 through the check valve 79, so the negative pressure can be The oil mist in the timing transmission chamber 48 is efficiently su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com