Method and apparatus for detecting stress of shaft journals on two end of submergence roller

A detection method and a technology of a detection device, which are applied in the direction of measuring devices, optical devices, and force measurement by measuring the frequency change of a stressed vibrating element, can solve the problems of journal seizure, increased journal wear, and journal stress. Problems such as uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

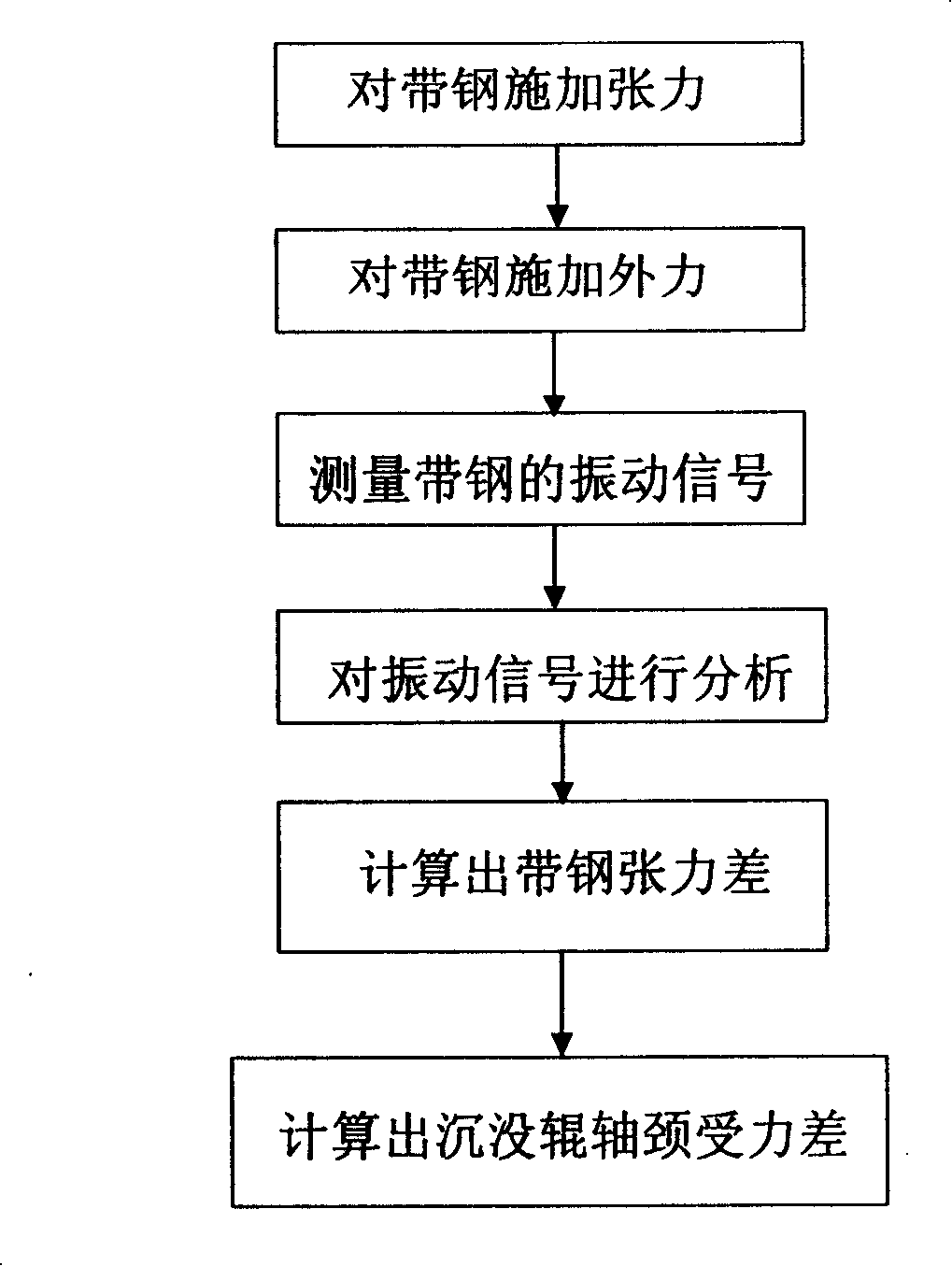

[0047] see image 3 As shown, the detection method of the journal force at both ends of the sinking roller of the present invention is specifically: after the sinking roller is installed in place, start the production unit to apply tension to the strip, and when the strip reaches the set tension, stop the unit and make the strip The steel remains in tension; the hand-held tool exerts a lateral force on the left side of the strip to offset the displacement of the strip, and then removes the tool suddenly to make the external force zero, so that the strip vibrates freely under the action of the initial displacement; see also Figure 4 As shown, the laser sensor is used to obtain the corresponding left part displacement vibration analog signal, and the low-pass filter is used to filter the vibration analog signal. Since the vibration frequency of the strip steel is less than 10 Hz, the cut-off frequency of the low-pass filter is set to 10 Hz. After filtering out the high-frequenc...

Embodiment 2

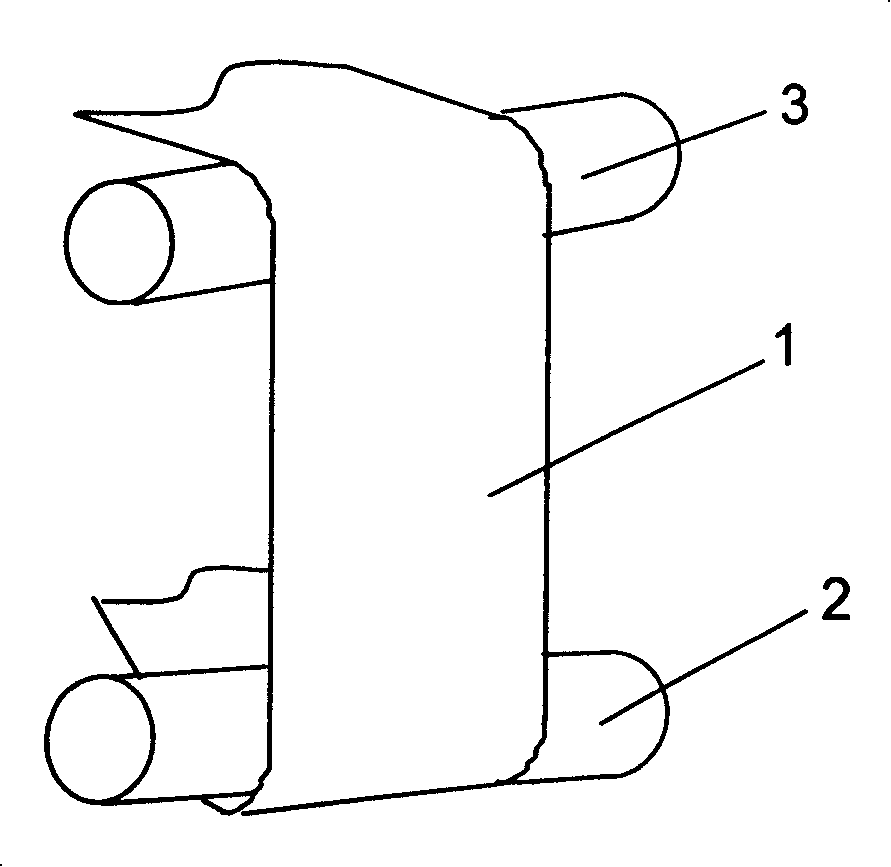

[0051] see Image 6 As shown, the detection device of the journal force at both ends of the sinking roller of the present invention includes a sensor and a force analyzer, and the sensor is a laser displacement sensor, which measures the displacement vibration of the left and right sides of the strip 1 respectively, and the measured vibration The analog quantity is transmitted to the force analyzer. The force analyzer further includes a low-pass filter, A / D converter, signal memory, FFT calculation unit, statistical average unit, maximum value extraction unit, and force calculation unit; the cut-off frequency of the low-pass filter is 10Hz, and the receiving sensor Input the vibration analog signal and filter out the high-frequency analog signal, input the obtained low-frequency analog signal into the A / D converter, and the A / D converter converts the low-frequency analog signal into a low-frequency digital signal and then input it into the signal memory and store it Save, can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com