Glass-ceramics used as ultrahard material grinding wheel bond and preparation method thereof

A technology of glass-ceramic and superhard material, applied in the field of glass-ceramic and its preparation, can solve the problems of low strength, high sintering temperature, low impact toughness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

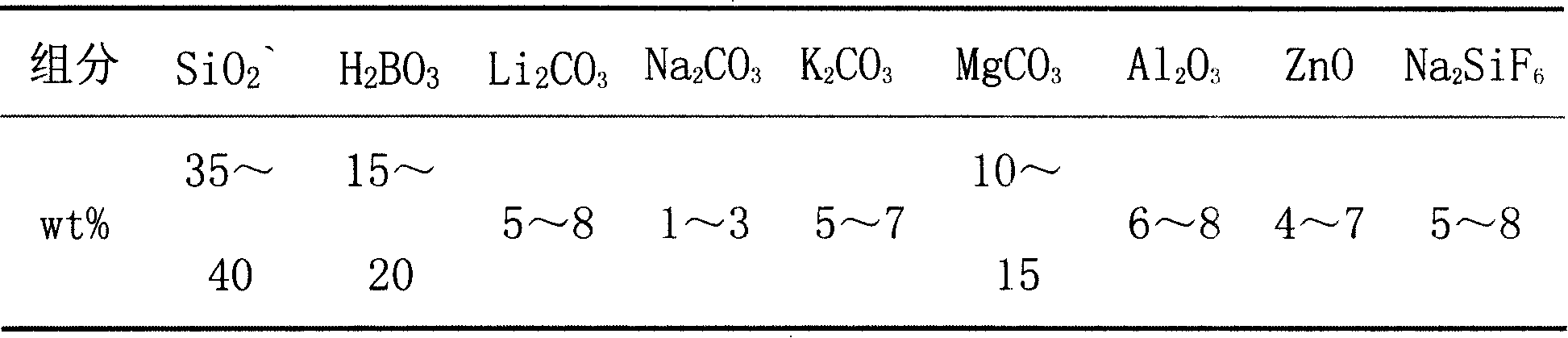

[0027] The raw materials used to prepare the basic glass include: industrial quartz, boric acid, aluminum oxide, zinc oxide, lithium carbonate, sodium carbonate, potassium carbonate, magnesium carbonate, etc., and sodium fluorosilicate is used as the crystal nucleus agent. The ratio range of raw materials is shown in in the table below:

[0028]

[0029] Weigh various raw materials according to the formula shown in the above table, mix them evenly by ball milling, put them into a high-alumina crucible, raise the temperature to 1300°C in an electric furnace, keep the temperature for 1 hour after reaching the predetermined temperature, pour the glass melt into water and quench it, The water-quenched glass slag is milled with a ball mill for 1h (800r / min), dried and sieved with a 200-mesh sieve for later use; the firing and crystallization process is to press the sifted glass powder into a sample, After drying, put it into a high-temperature furnace with a heating rate of 3-5°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com