Method for extracting high-purity ultra-fine alumina from coal ash

A technology of ultra-fine alumina and fly ash, applied in chemical instruments and methods, alumina/aluminum hydroxide, inorganic chemistry, etc., can solve the problems of complicated process, secondary pollution, low alumina extraction rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

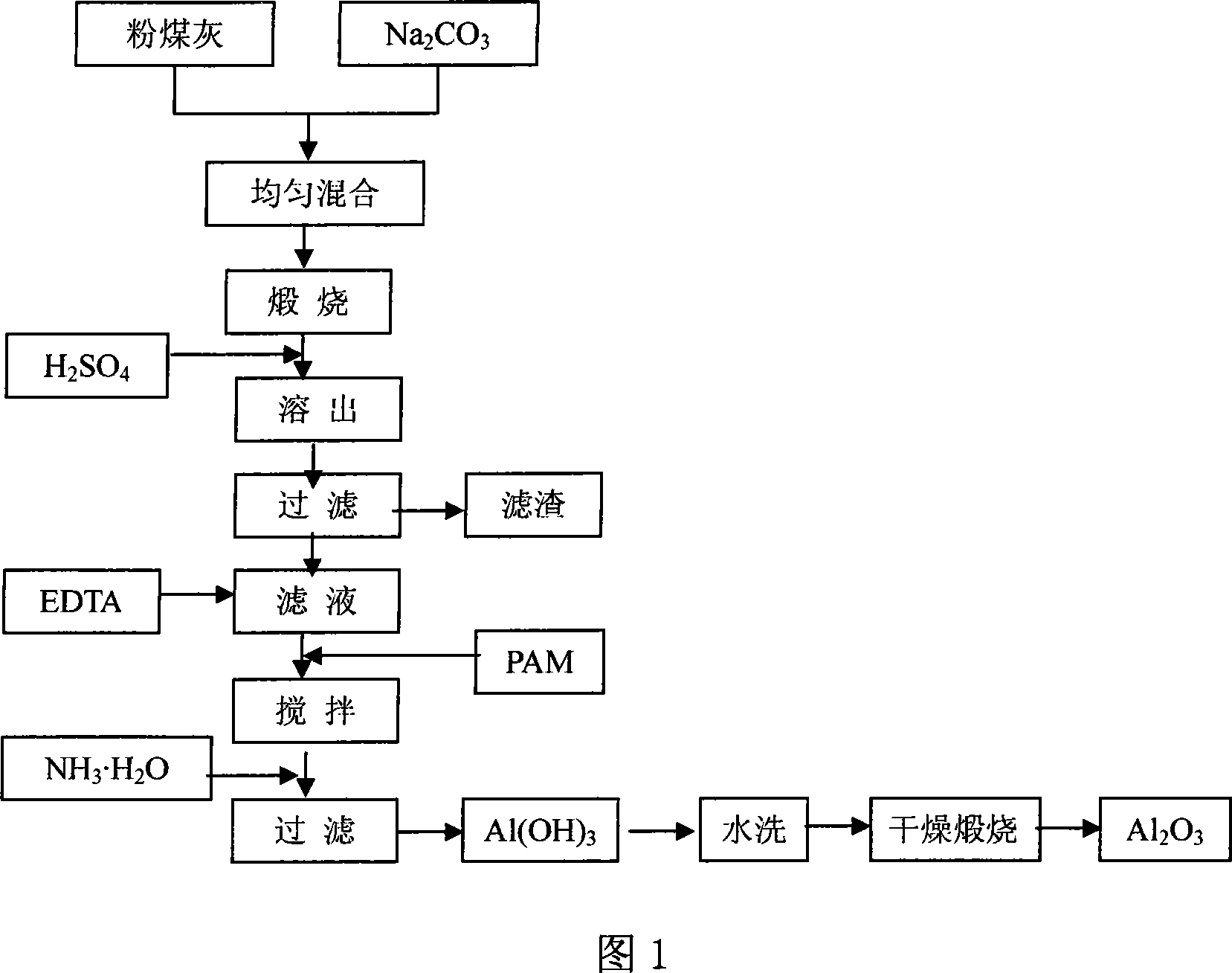

Method used

Image

Examples

Embodiment 1

[0062] 1. Fly ash calcination activation process

[0063] Na 2 CO 3 Na by weight ratio with fly ash 2 CO 3 / Al 2 o 3 (Contained in fly ash) = 1:1 uniform mixing, after grinding through a 100-mesh sieve, place in a muffle furnace and calcinate at 900°C for 2h.

[0064] 2. Active fly ash dissolution, purification and refinement process

[0065] 1.0mol / L of H 2 SO 4 Mix with the activated fly ash at a volume ratio of 5:1, stir evenly, and heat up to 70°C for 2 hours to dissolve. The aluminum in the activated fly ash is transferred into the solution. After filtering, the remaining waste residue and the eluate containing aluminum are obtained.

[0066] During the dissolution process, a part of the iron salt in the activated fly ash participates in the reaction and enters the dissolution solution, so the dissolution solution contains a small amount of Fe 3+ , which was removed by complexometric titration. Adding concentration is 0.003mol / L ethylenediaminetetraacetic acid...

Embodiment 2

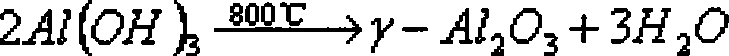

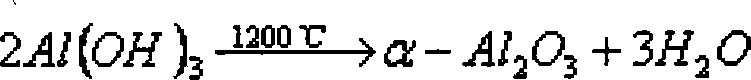

[0072] The preparation process steps are the same as in Example 1, except that the final heat treatment temperature is different during the heat treatment process. In this example, the activation temperature of step 1 in a muffle furnace will be changed to 900°C for calcination for 2 hours.

Embodiment 3

[0074] The preparation process steps are the same as in Example 1, except that the final heat treatment temperature is different during the heat treatment process. In this example, the activation temperature of step 1 in a muffle furnace will be changed to 950°C for calcination for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com