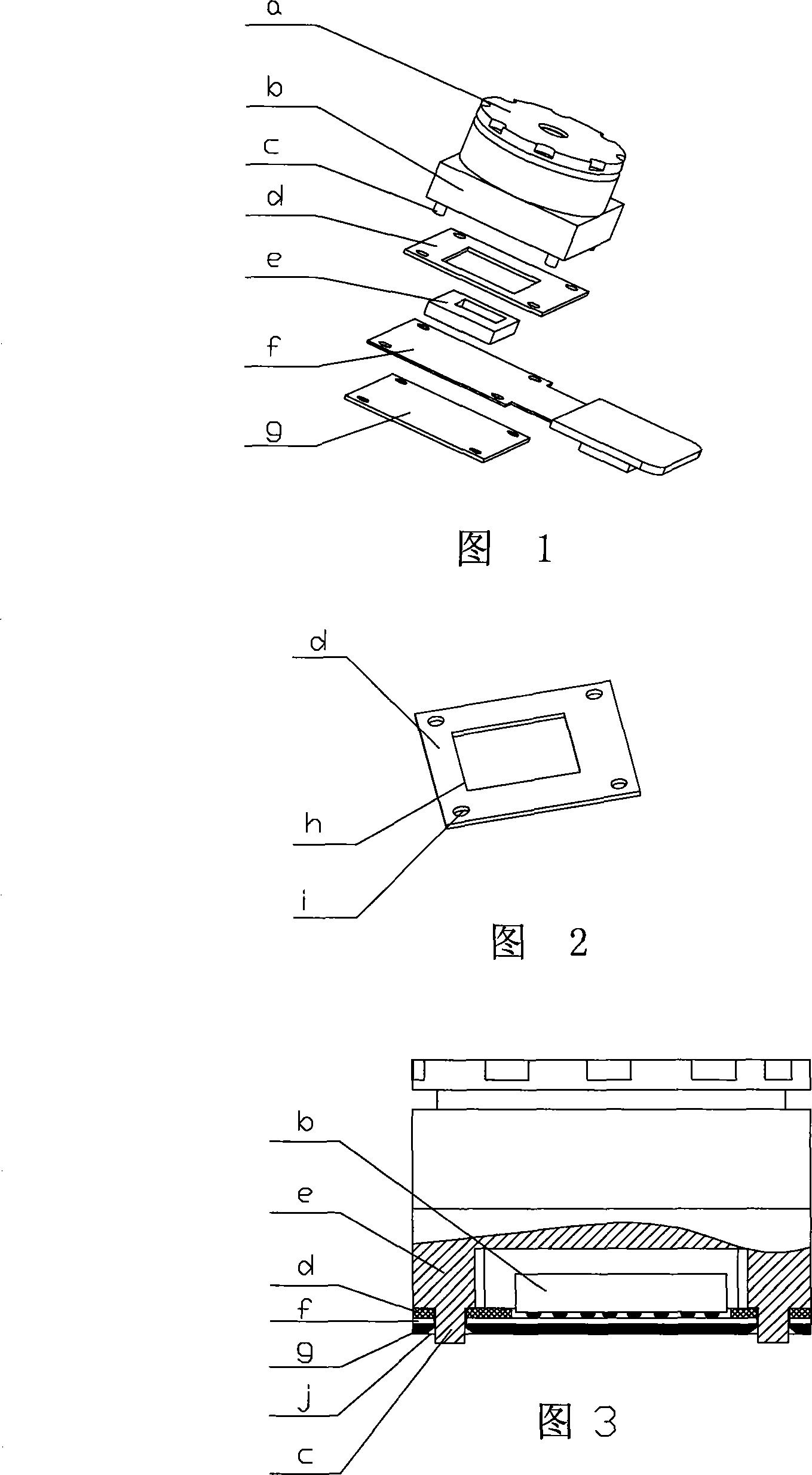

Lens two-sided glue assembly technology for mobile phone camera shooting module group of flexible circuit board

A technology of flexible circuit boards and camera modules, which is applied in the selection and arrangement of radio/inductive links, printed circuits connected with non-printed electrical components, installation, etc., and can solve problems such as desoldering, poor conductivity of metal contact points, and disassembly Difficulties and other problems, to achieve the effect of improving product yield and saving production man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Prepare the lens and lens holder: The function of lens a is to collect light for the image sensor. The inside of lens a is an optical system composed of several lenses. The lens is installed in the lens barrel, and the outside of the lens barrel is threaded. The mirror mount b is a bridge connecting the flexible circuit board and the lens, and at the same time provides a dark room for the lens a to cover the external light for the lens a to image, and has the function of dustproof. There is a lens mounting hole at one end of the mirror holder b, and there is a screw thread inside, the lens a is just screwed in the mirror holder b, and the material of the mirror holder b is plastic. Four positioning columns c are made on the end surface of the mirror base b that is attached to the flexible circuit board f, which are used for the installation and positioning of the mirror base b and the hot riveting mentioned in step 9 later. In order to ensure the adhesion strength, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com