Load type catalyst for olefinic polymerization and method for producing the same

A supported catalyst, olefin polymerization technology, applied in the production of bulk chemicals, etc., can solve the problem of narrow molecular mass distribution of polypropylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

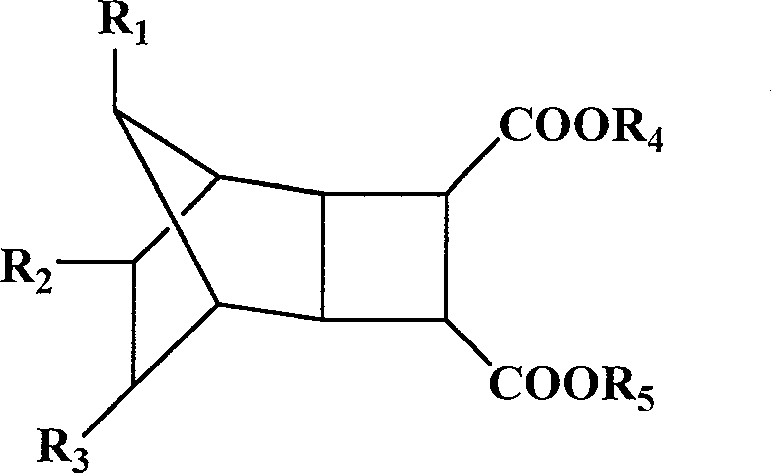

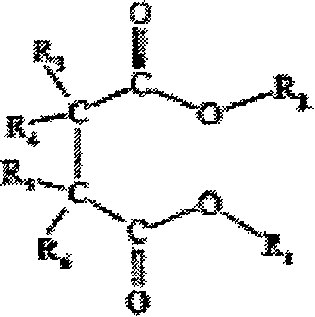

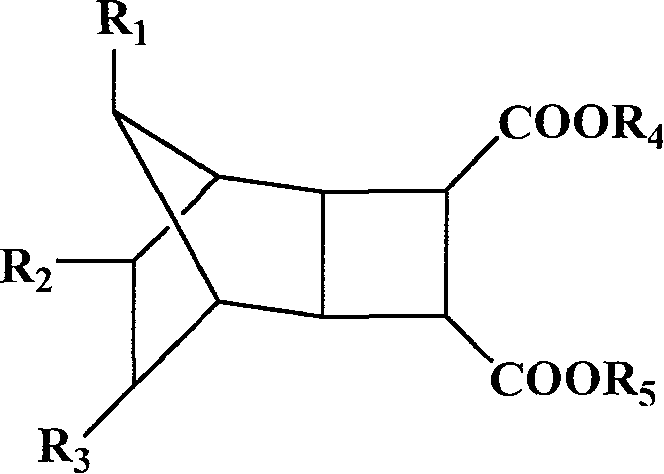

[0083] Example 1 Synthesis of bicyclo[2,2,1]-2,3-α,β ethyl succinate

[0084] In 150 mL of dichloromethane, add 1.17 g of maleic anhydride, 5.00 g of norbornene, and 0.58 g of benzophenone, and irradiate with ultraviolet light for 12 hours while stirring. After removing the solvent, add 30mL ethanol, 3mL H 2 SO 4 , heated to reflux at 100°C for 4 hours. After removing the solvent, extract with 3×50 mL ether, wash with saturated sodium bicarbonate solution, and dry over anhydrous magnesium sulfate. After removing ether, distill under reduced pressure at 104°C (10 mmHg) to obtain 1.51 g of ethyl bicyclo[2,2,1]-2,3-α,β-succinate as a colorless liquid.

[0085] through 1 H NMR (CDCl 3 , 300MHz) Analysis result: δ1.07(m, 3H, CH 2 ); δ1.30(t, 3H, CH 3 ); δ1.50(m, 5H, CH 2 , CH); δ2.18(d, 2H, CH); δ3.38(m, 2H, CH); δ4.24(q, 2H, CH 2 ).

Embodiment 2

[0086] Example 2 Synthesis of bicyclo[2,2,1]-2,3-alpha,beta methyl succinate

[0087] Except that methanol was used instead of ethanol in the synthesis, all the other steps were the same as in Example 1. At 102°C (10mmHg), 1.38g of methyl bicyclo[2,2,1]-2,3-α,βsuccinate was obtained as a colorless liquid.

[0088] through 1 H NMR (CDCl 3 , 300MHz) analysis results: δ1.30-1.60 (m, 8H, 2CH, 6CH 2 ); δ1.73(q, 1H, CH); δ2.04(q, 1H, CH); δ3.10(t, 1H, CH); δ3.67(s, 3H, CH 3 ).

Embodiment 3

[0089] Example 3 Synthesis of diethyl bicyclo[2,2,1]-2,3-alpha,beta succinate

[0090] In 150 mL of dichloromethane, add 1.17 g of maleic anhydride, 5.00 g of norbornene, and 0.58 g of benzophenone, and irradiate with ultraviolet light for 12 hours while stirring. After the solvent was removed, 30 mL of ethanol and 0.1 g of p-toluenesulfonic acid were added, and heated to reflux at 100° C. for 48 hours. After removing the solvent, extract with 3×50 mL ether, wash with saturated sodium bicarbonate solution, and dry over anhydrous magnesium sulfate. After filtering to remove the ether, 1.67 g of diethyl dicyclo[2,2,1]-2,3-α,β-succinate was obtained as colorless viscous bicyclo[2,2,1]-2,3-α,β.

[0091] through 1 H NMR (CDCl 3 , 300MHz) analysis results: δ1.30-1.55 (m, 12H, 6CH 2 , 6CH 3 ); δ2.04(m, 2H, CH); δ3.14(m, 2H, CH); δ4.12(m, 4H, CH 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com