Concrete and preparation method thereof, and method for treating refuse burning ash

A waste incineration ash and concrete technology, which is applied in the field of building materials, can solve the problems of land occupation by waste incineration ash, achieve efficient environmental protection treatment, reduce land occupation and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0037] Implementation plan 1: the ratio of making permeable bricks and heat insulation bricks

[0038] water

Embodiment approach 2

[0039] Implementation plan two: the ratio of making hydraulic bricks

[0040] water

ceramic aggregate

Garbage incineration ash

the sand

0.38

1

1.8

1.78

0.2

0.04

0.5

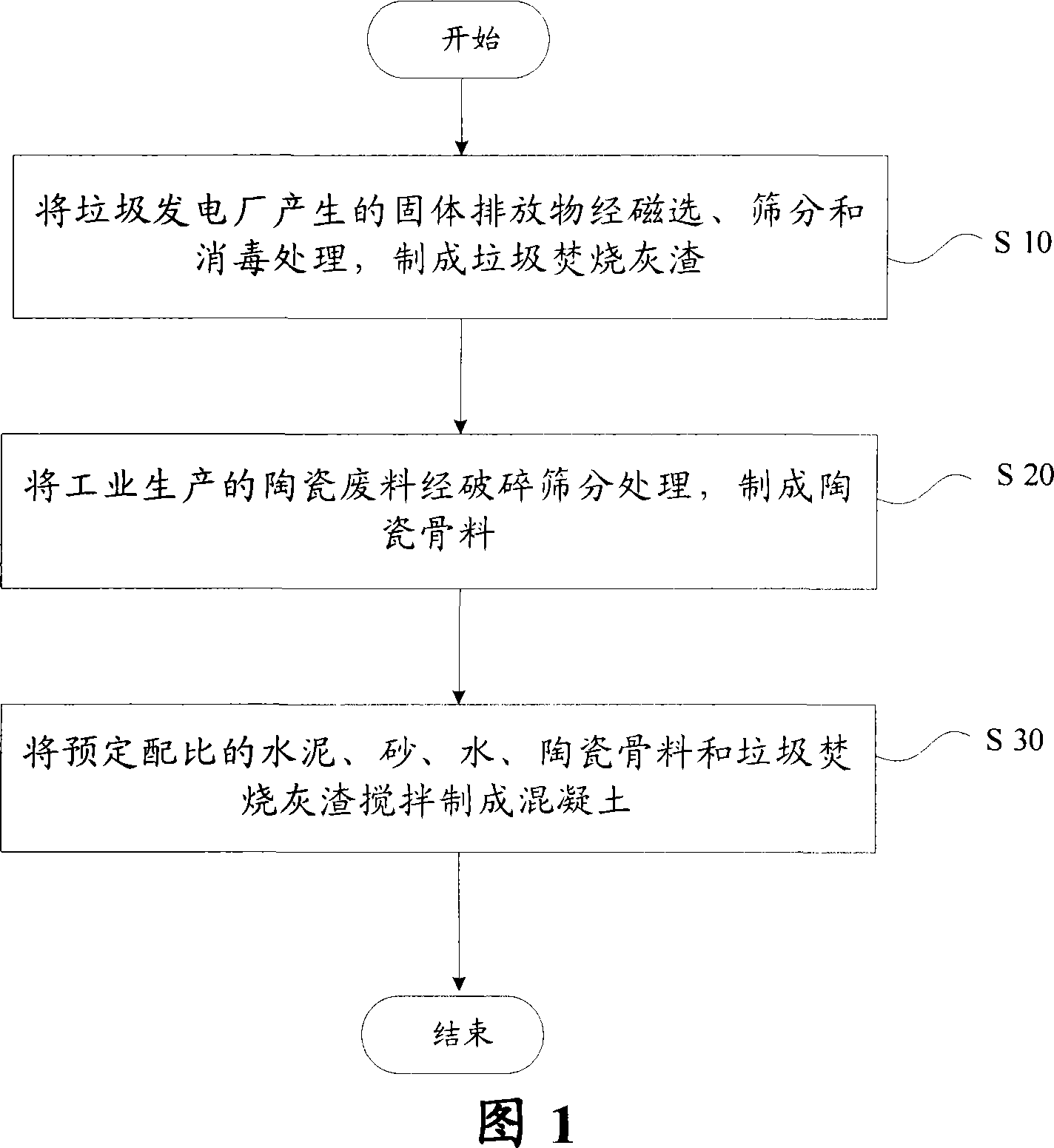

[0041] Fig. 1 shows the flow chart of the preparation method of concrete according to the embodiment of the present invention, comprises the following steps:

[0042] Step S10, subjecting the solid discharge generated by the waste-to-energy plant to magnetic separation, screening and disinfection to produce waste incineration ash;

[0043] Step S20, crushing and screening industrially produced ceramic waste to produce ceramic aggregate; and

[0044] Step S30, mixing cement, sand, water, ceramic aggregate and waste incineration ash in predetermined proportions to make concrete.

[0045] The above concrete preparation method makes full use of various solid waste resources, and can effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com