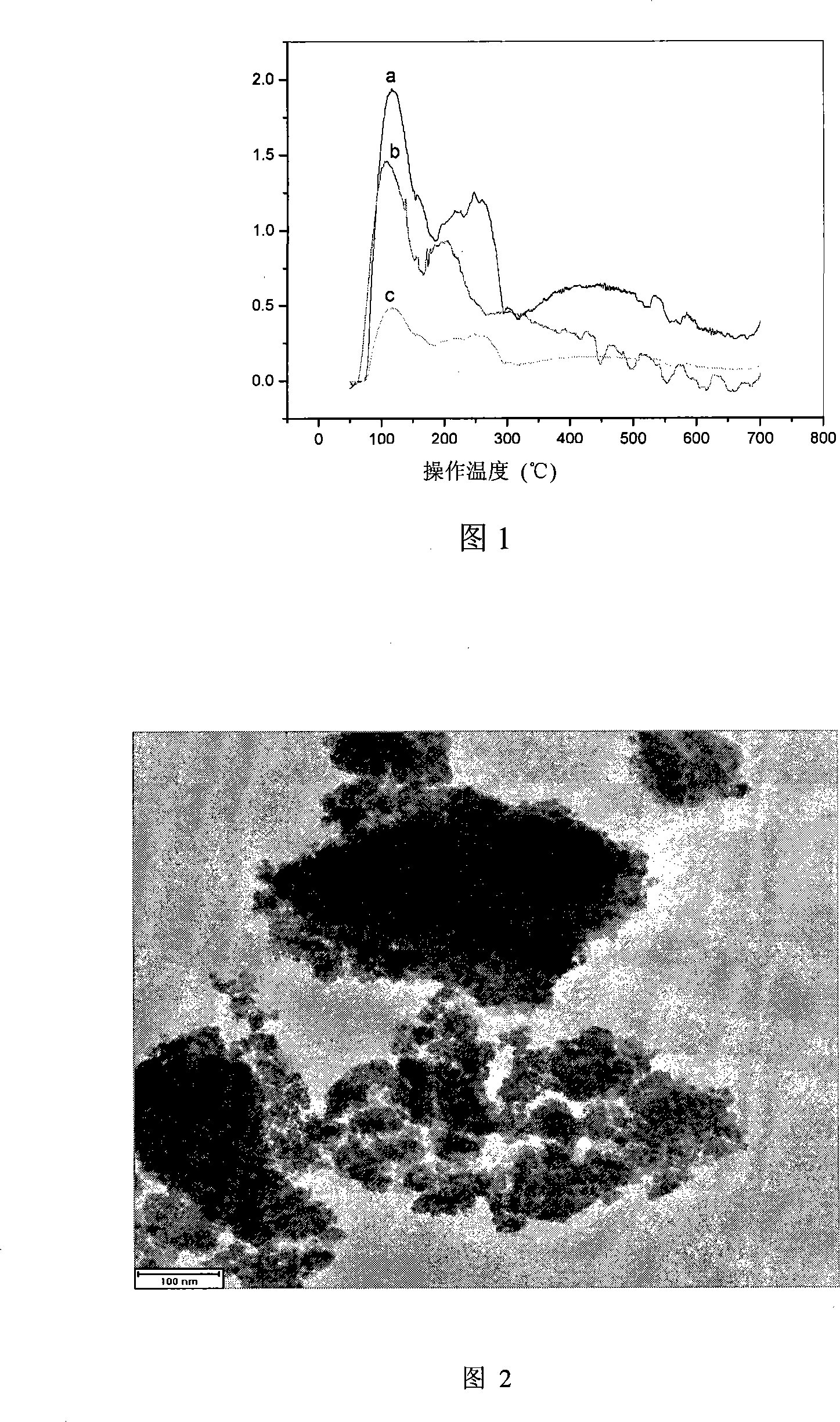

W-Sn nano composite metal oxide gas-sensing material and preparation method thereof

A technology of nano-composite and gas-sensing materials, applied in the field of binary nano-composite metal oxide gas-sensing materials and their preparation, to achieve the effects of high adsorption performance, high sensitivity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A. Weigh 1.7529g of SnCl 4 ·5H 2O was fully dissolved in 100ml distilled water to prepare 0.05M SnCl 4 Solution, add dilute ammonia solution drop by drop under constant stirring, stop dropping when the pH value of the solution reaches 8, and obtain α-stannic acid sol precipitation, then place it for aging for 2 hours, filter, and disperse and dissolve the filtered sol in 50ml distilled water Make the concentration 0.1M.

[0024] B. Weigh 0.3154g of (NH 4 ) 6 h 2 W 12 o 40 4H 2 O was dissolved in 12.5ml of water to make a concentration of 0.1M (NH 4 ) 6 h 2 W 12 o 40 solution, and then added dropwise to the above-mentioned 50ml α-stannic acid sol solution, the pH of the solution was 7, and then added dilute HNO 3 Solution, finally make the pH value of the solution to be 6, place it at room temperature for 24 hours, centrifuge at 4200rmp, dry the separated precipitate at 70°C, and roast at 600°C for 6 hours to obtain WO 3 -SnO 2 Composite powder, the measur...

Embodiment 2

[0026] A. with embodiment 1;

[0027] B. 0.3262g of 5 (NH 4 ) 2 O·12WO 3 ·5H 2 O was dissolved in 12.5ml of distilled water, adjusted with concentrated nitric acid to make the pH value 1, then added dropwise in the above-mentioned 50ml α-stannoic acid sol solution, and finally the pH value of the solution was adjusted to 6 with dilute ammonia to make it completely precipitated, Others are the same as in Example 1, and finally the mole of Sn / W is 4:1 WO 3 -SnO 2 Composite powder. The measured average particle size of the material is about 15nm, and the specific surface area is 43.1m 2 / g.

Embodiment 3

[0029] A. with embodiment 1;

[0030] B. Add 0.8411g of (NH 4 ) 6 h 2 W 12 o 40 4H 2 O is dissolved in 33.3ml distilled water, and others are the same as in Example 1. Preparation of WO with a Sn / W molar ratio of 1.5:1 3 -SnO 2 Composite powder. The measured average particle size of the material is about 7nm, and the specific surface area is 51.1m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com