Air conditioner oil returning system

An oil return system, air conditioner technology, applied in refrigeration safety arrangements, refrigerators, lighting and heating equipment, etc., can solve the problems of compressor 11 damage, low suction pressure of compressor 11, easy to generate noise, etc. Work effect, reduce the possible effect of refrigerant backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

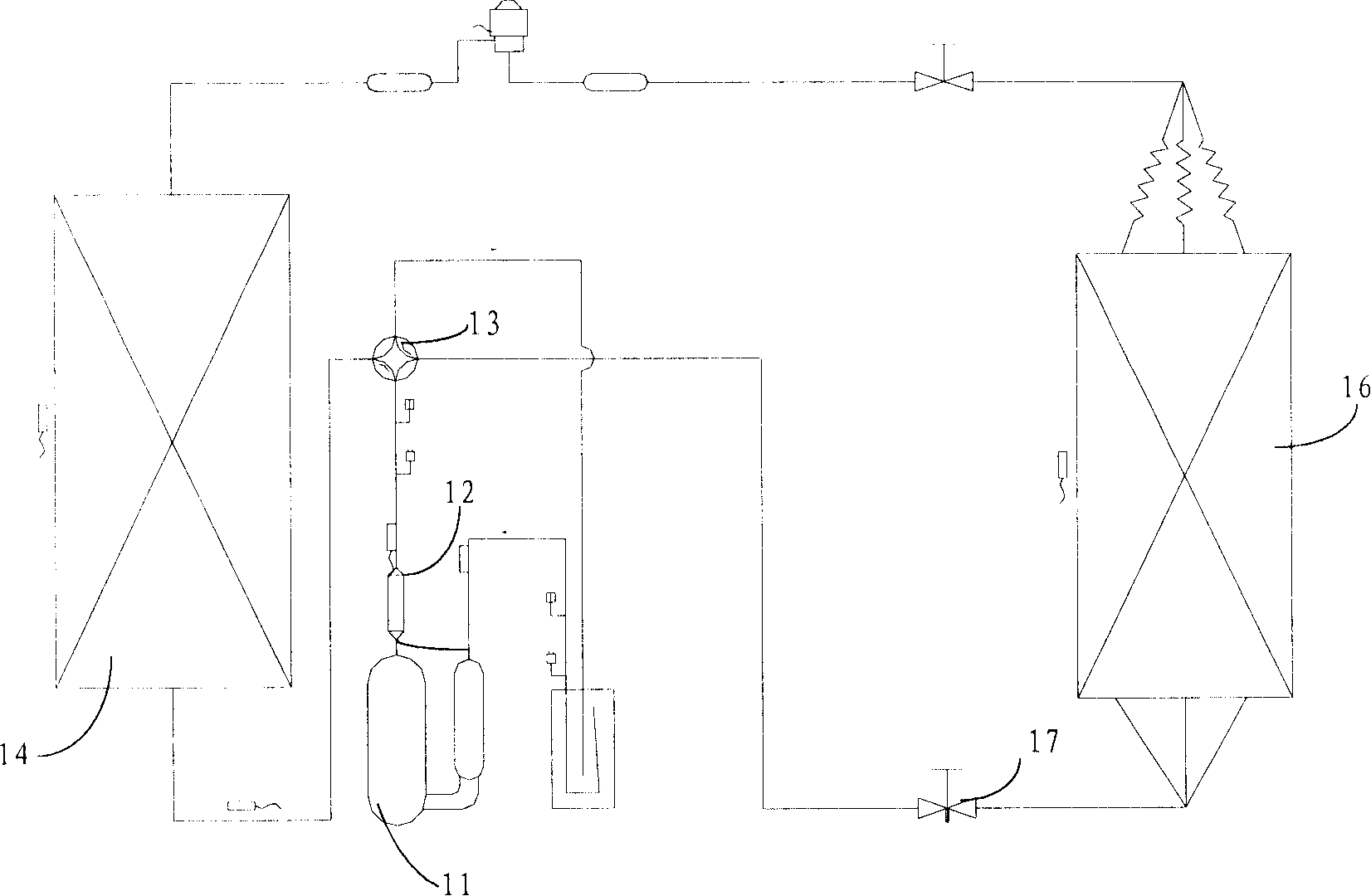

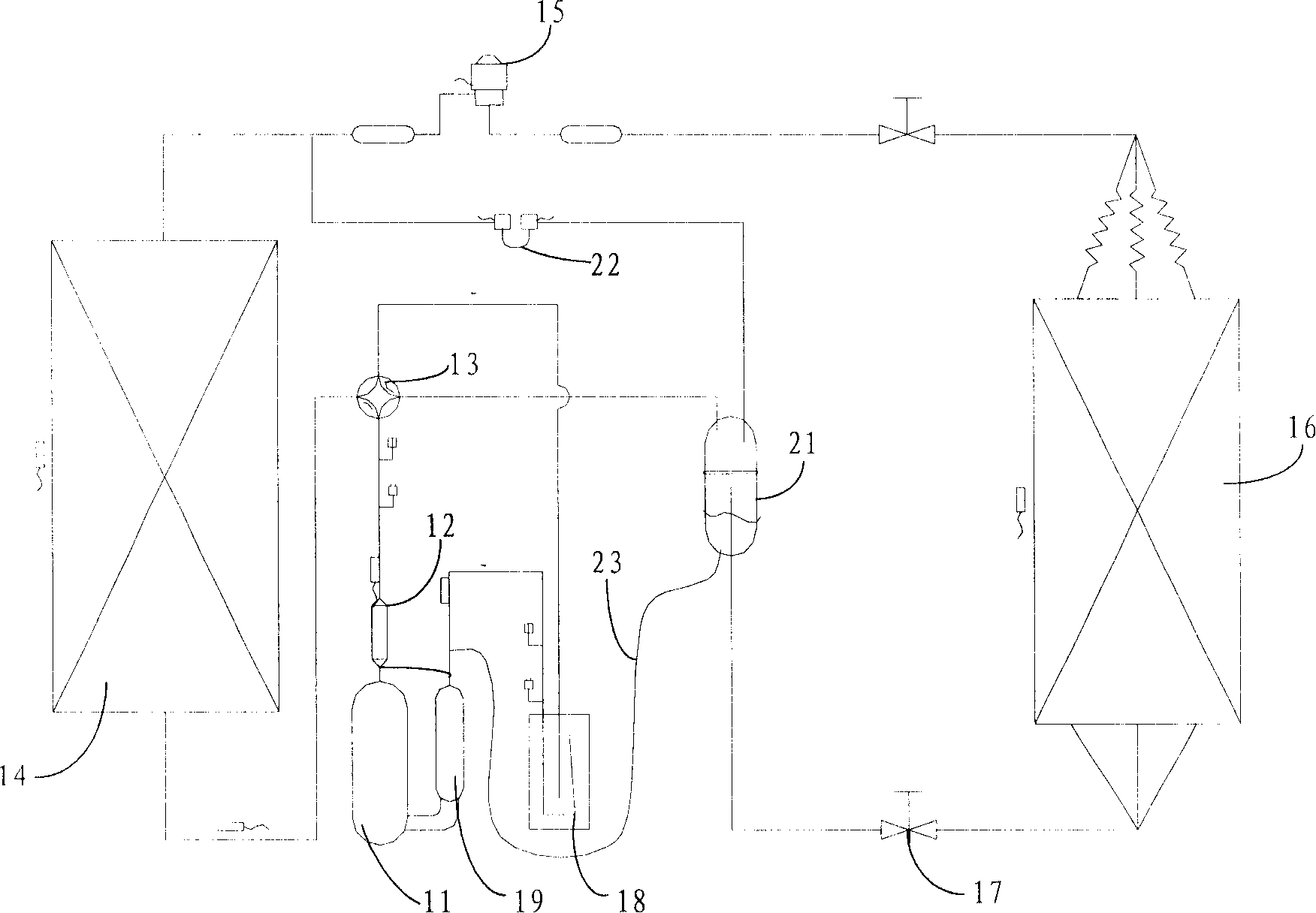

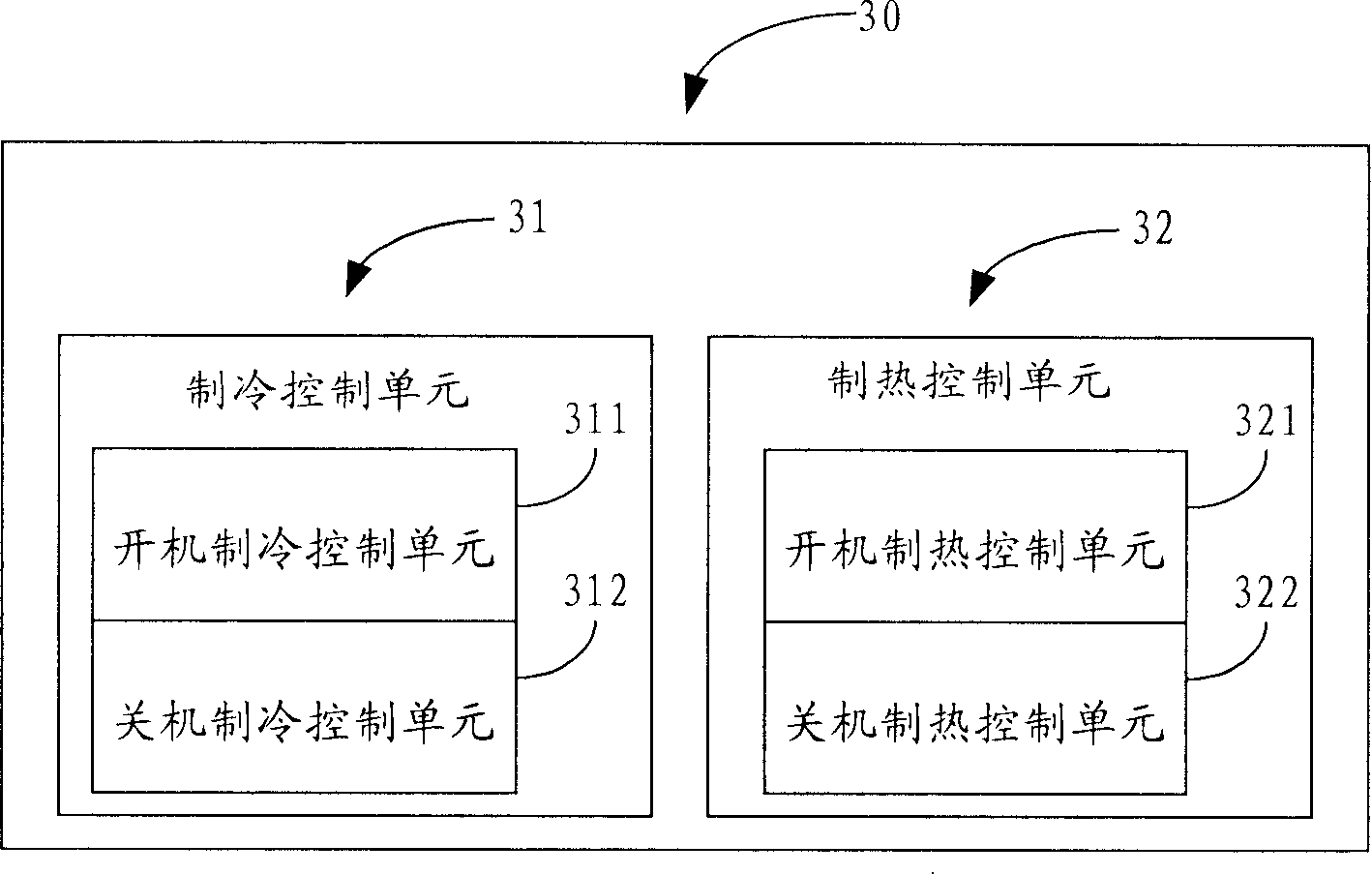

[0027] The core idea of the present invention is to install an oil separator between the four-way valve and the evaporator, and the oil separator can be connected to the condenser through the electromagnetic valve, and connected to the suction pipe of the compressor through the oil return capillary. When the air conditioner is working, by controlling the opening and closing of the solenoid valve and the expansion valve, the internal pressure of the oil separator is effectively controlled, and the low pressure on the suction side of the compressor is used to automatically complete the oil return, realizing the effective compensation of secondary oil return and automatic oil separation An oil separation device is installed at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com