Method for preparing boron phenolic/in-situ nano hybrid compound resin

A boron phenolic resin and hybrid composite technology are applied in the field of preparation of boron phenolic/in-situ nano-hybrid composite resin, which can solve problems such as the inability to ensure uniform dispersion of nanoparticles, and achieve hydrolysis resistance stability, easy operation and control. , the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

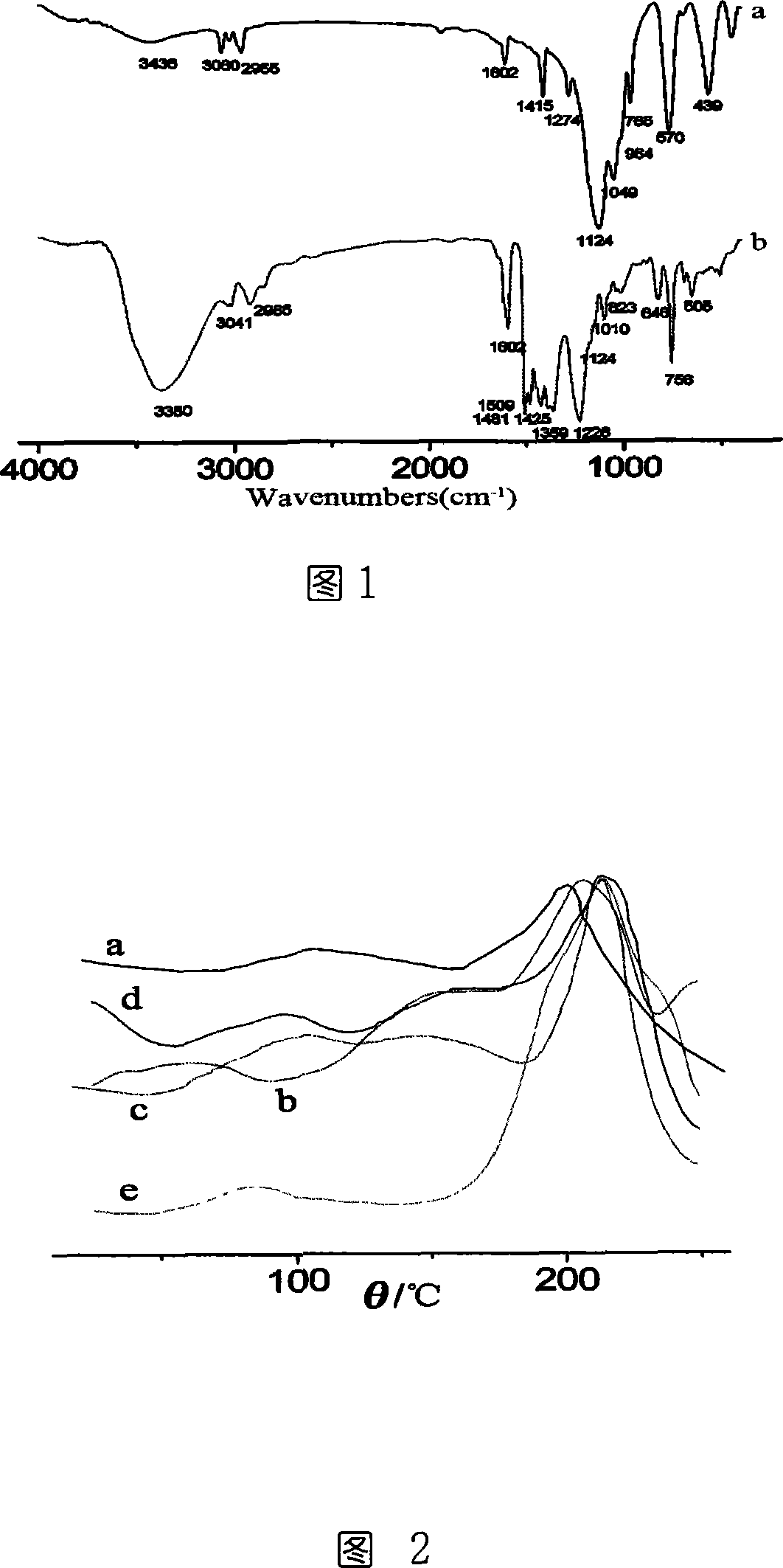

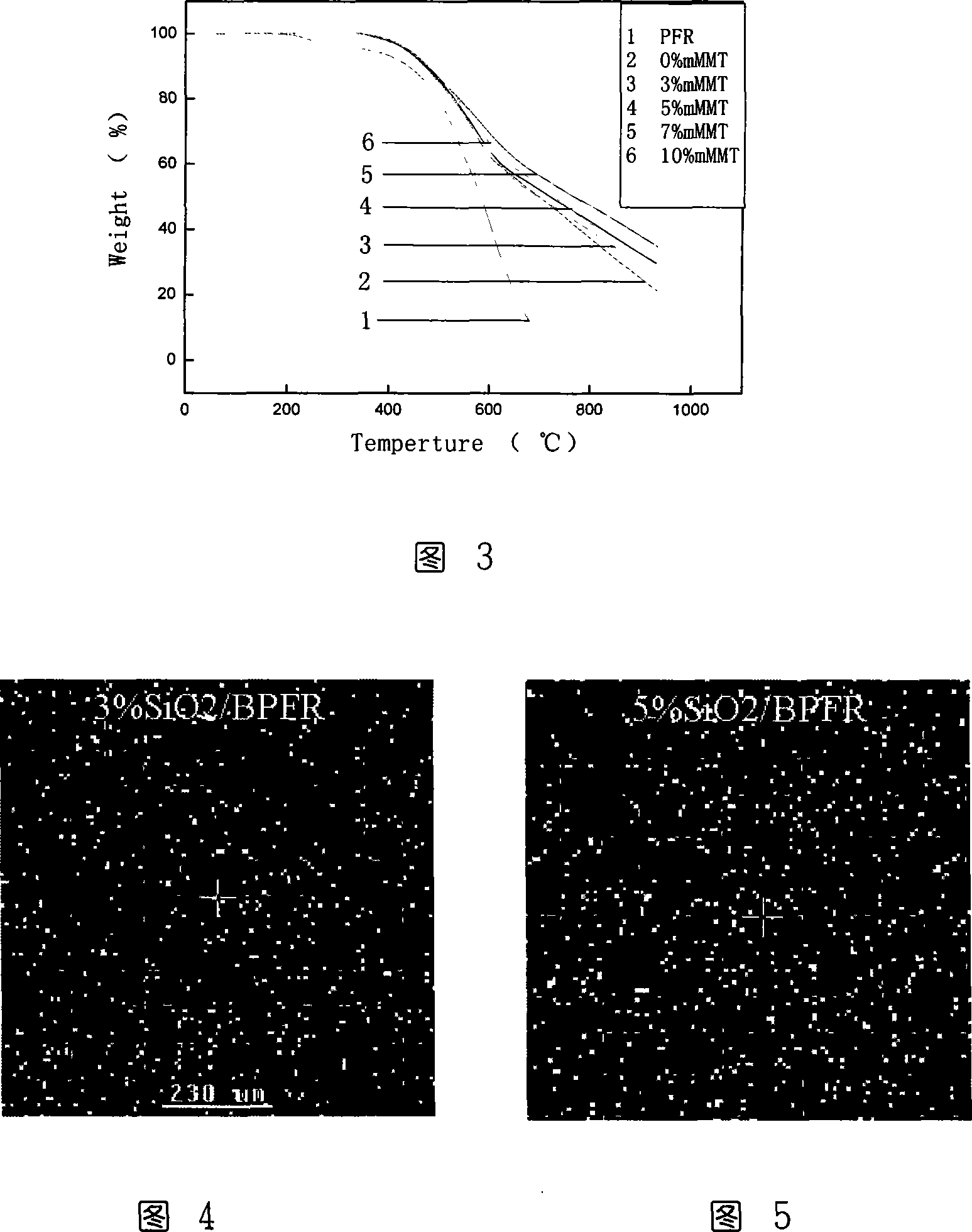

[0034] Embodiment 1: Preparation of boron-nitrogen coordination boron phenolic resin / nano-montmorillonite composite resin

[0035](1) The synthesis of boron-nitrogen coordination compound is added in the reaction flask according to the molar ratio of boric acid and phenol 1:2, and an appropriate amount of 30-50mL toluene is added, the temperature is raised to reflux, and the esterification reaction water is continuously separated by the oil-water separator, At the same time, the reaction temperature is gradually increased to accelerate the esterification reaction, and the reaction temperature is controlled at 110-160° C. until the theoretical dehydration amount is reached, and the reaction is terminated. After the temperature of the reaction system drops below 100°C, add 1 mole of aminoethanol to continue the reaction until complete to obtain a purple-red coordination type triphenyl borate monomer.

[0036] (2) Add paraformaldehyde or paraformaldehyde according to the molar ra...

Embodiment 2

[0040] Embodiment 2: boron nitrogen coordination boron phenolic resin / nanometer SiO 2 Preparation of composite resin

[0041] (1) same as embodiment 1;

[0042] (2) Trimeric or paraformaldehyde, 0.01 oxalic acid or NaOH of 1.2-1.4 times molar weight of phenol molar weight are added in the second stage of reaction, while adding tetramethoxysilane or tetramethoxysilane of 6-30% of phenol weight Ethoxysilane, react at 80-140°C for 1-2 hours. In the later stage of the reaction, water, solvent toluene or xylene and hydrolysis product methanol or ethanol are removed under reduced pressure. As the dehydration reaction under reduced pressure proceeds, the viscosity of the system continues to increase, and the reaction can be accelerated by appropriately increasing the reaction temperature (controlled below 140°C) to reduce the viscosity of the system until the polyoxymethylene is fully reacted, and purple-yellow solid boron nitrogen can be obtained Coordinated boron phenolic / nano-S...

Embodiment 3

[0044] Embodiment 3: Formaldehyde aqueous solution method prepares boron phenolic / nanometer montmorillonite composite resin

[0045] (1) Add phenol and 37% formaldehyde aqueous solution into the reaction flask according to the molar ratio of phenol and formaldehyde 1: 1.2, and add NaOH or Ba(OH) of 0.02-.0.05 molar amount of phenol at the same time 2 Solution, heated up and reacted at 60-70°C for 60 minutes, dehydrated under reduced pressure to obtain salicyl alcohol;

[0046] (2) Adding boric acid at a molar ratio of phenol to boric acid 3:0.5-1.0 and simultaneously heating up the reaction, controlling the reaction temperature at 100-105° C.;

[0047] (3) After the above reaction for 30-60 minutes, add 3-15% organic montmorillonite based on the weight of phenol, and continue to react under this condition for 30-60 minutes, dehydrating under reduced pressure. Control the reaction temperature between 105-115°C while avoiding gelation. The end point of the reaction can be trac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com