Method for preparing aluminum matrix composite material through synergism of alterant and carbon nano-materials

An aluminum-based composite material and carbon nanomaterial technology, which is applied in the field of metal material manufacturing, can solve the problems of reducing the mechanical properties of materials, and carbon nanotubes are prone to agglomeration, and achieve the effects of reducing structural damage, eliminating hydrogen absorption, and combining well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

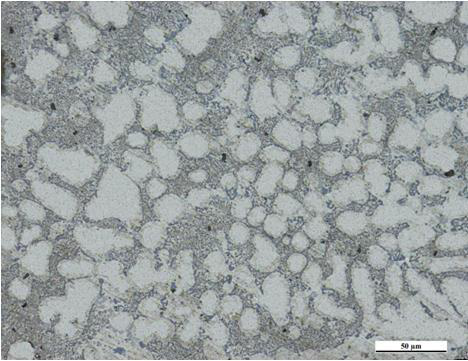

Image

Examples

Embodiment 1

[0021] (1) Take Al-Si-Cu alloy (the mass percentage of Si is 10.5%, the mass percentage of Cu is 3.5%, and the balance is Al), Al-8Sr master alloy (the mass percentage of Sr is 8%), Al The -5C intermediate prefabricated block (the mass percentage of C is 5%) is dried in a vacuum drying oven for later use.

[0022] (2) Put the matrix alloy into a graphite crucible and heat up to 740°C, and remove the scum on the surface after it is completely melted. Then add the Al-8Sr master alloy covered with aluminum foil in batches according to the proportion, the total addition of Sr accounts for 0.04wt.% of the total weight of the melt, and apply high-energy ultrasound while adding Sr, and the ultrasonic horn probe extends into the melt The depth in the center is about 3mm, the ultrasonic power is 1.4kW, the ultrasonic frequency is 20kHZ, and the ultrasonic time is 5min. After ultrasonication, the alloy melt was heated to 770 °C for 30 min to ensure that Sr was completely melted into th...

Embodiment 2

[0026] (1) Take Al-Si-Cu alloy (the mass percentage of Si is 11.0%, the mass percentage of Cu is 3.2%, and the balance is Al), Al-9Sr master alloy (the mass percentage of Sr is 9%), Al The -6C intermediate prefabricated block (the mass percentage of carbon nanofibers is 6%) was dried in a vacuum drying oven for later use.

[0027] (2) Put the matrix alloy into a graphite crucible and heat it up to 750°C, and remove the scum on the surface after it is completely melted. Then add the Al-9Sr master alloy covered with aluminum foil in batches according to the proportion, the total addition of Sr accounts for 0.05wt.% of the total weight of the melt, and apply high-energy ultrasound while adding Sr, and the ultrasonic horn probe extends into the melt The depth in the center is about 4mm, the ultrasonic power is 2.1kW, the ultrasonic frequency is 20kHZ, and the ultrasonic time is 8min. Then the alloy melt was heated to 780°C for 35 min to ensure that Sr was completely melted into t...

Embodiment 3

[0033] (1) Take Al-Si-Cu alloy (the mass percentage of Si is 11.5%, the mass percentage of Cu is 3.0%, and the balance is Al), Al-10Sr master alloy (the mass percentage of Sr is 10%), Al The -7C intermediate prefabricated block (the mass percentage of carbon nanofibers is 7%) was dried in a vacuum drying oven for later use.

[0034] (2) Put the matrix alloy into a graphite crucible and heat up to 740°C, and remove the scum on the surface after it is completely melted. Then add the Al-10Sr master alloy covered with aluminum foil paper in batches according to the proportion, the total addition of Sr accounts for 0.06wt.% of the total weight of the melt, and apply high-energy ultrasound while adding Sr, and the ultrasonic horn probe extends into the melt The depth in the center is about 5mm, the ultrasonic power is 2.8kW, the ultrasonic frequency is 20kHZ, and the ultrasonic time is 10min. Then the alloy melt was heated to 780 °C for 40 min to ensure that Sr was completely melte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com