Silanylamine-based compound, method of preparing the same and organic light emitting device including organic layer comprising the silanylamine-based compound

A technology of silylamine and compound, which is applied in the field of organic light-emitting devices of silylamine compounds, their preparation methods and organic layers containing them, and can solve the problems of lifespan, efficiency and energy consumption of organic light-emitting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

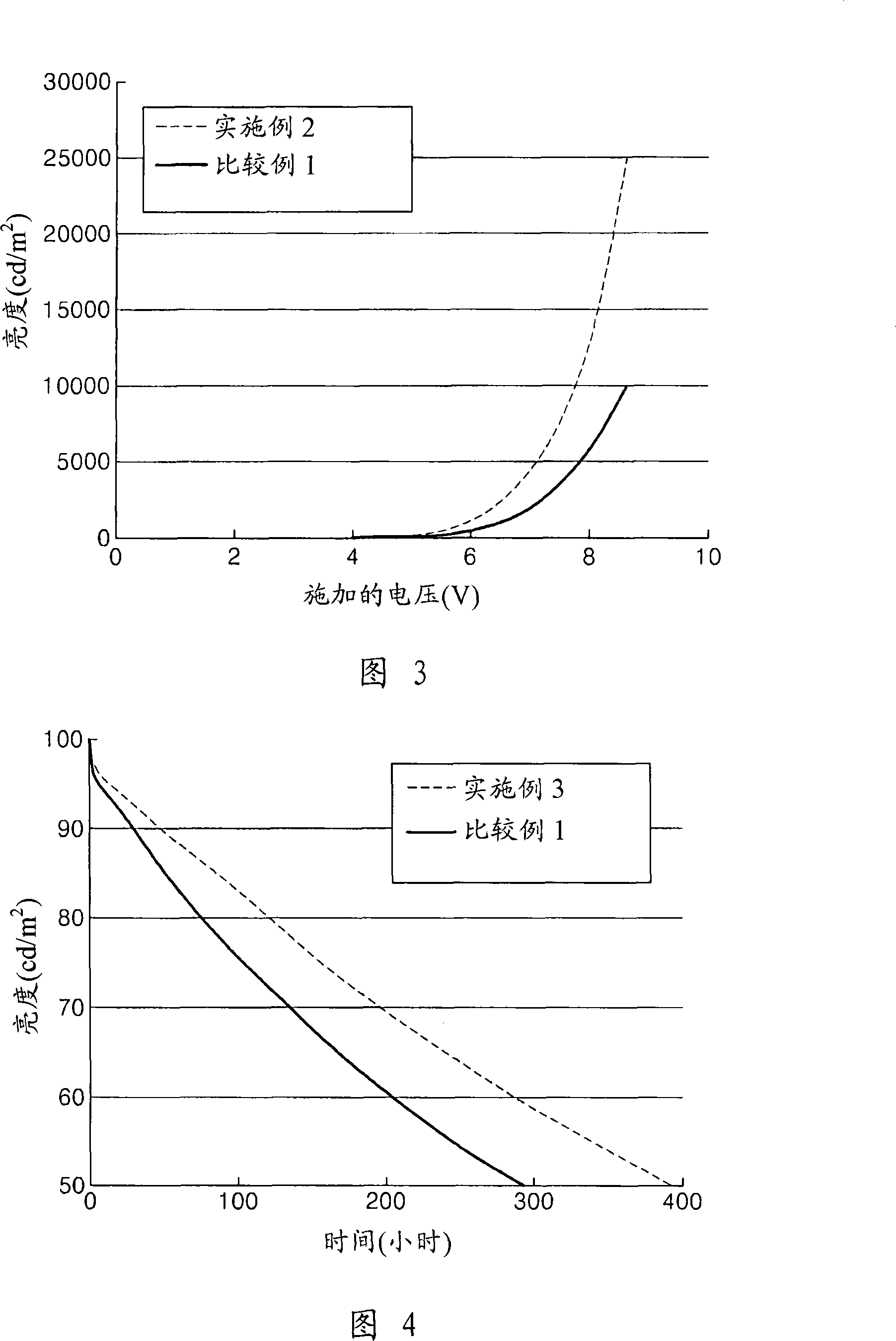

Embodiment 1

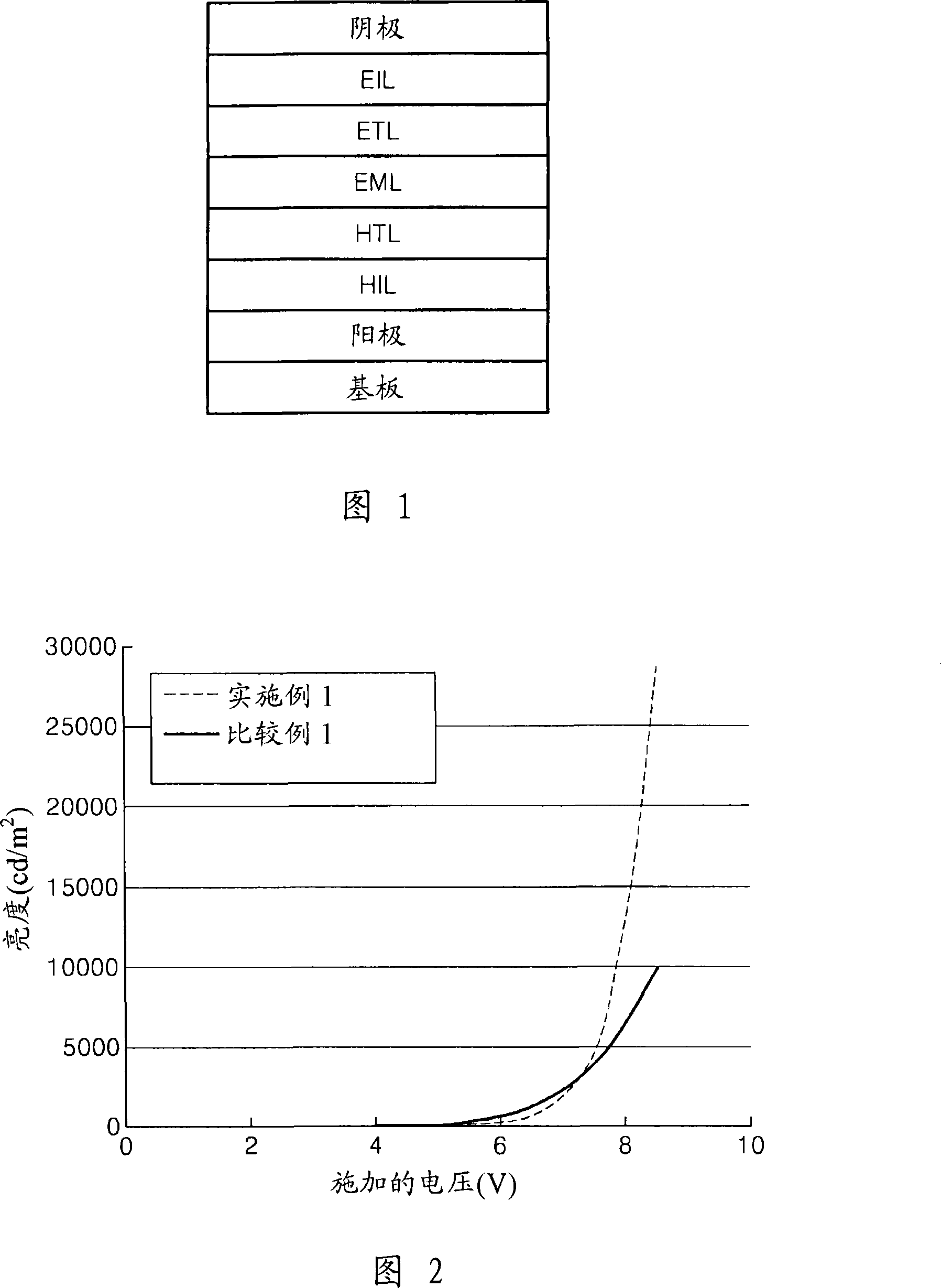

[0173] The corning's 15Ω / cm 2 (1,200 Ȧ) ITO glass substrates were cut into pieces of 50 mm×50 mm×0.7 mm in size, cleaned ultrasonically with isopropanol for 5 minutes, ultrasonically cleaned with deionized water for 5 minutes, and cleaned with UV ozone for 30 minutes. Then, this glass substrate was installed in a vacuum deposition apparatus.

[0174] Compound 9 was vacuum deposited on the substrate to form a HIL with a thickness of 600 Ȧ. 4,4'-bis[N-(1-naphthyl)-N-phenylamino]biphenyl (NPB) was vacuum deposited on the HIL to form the HTL with a thickness of 300 Ȧ.

[0175] IDE215 (a blue fluorescent host obtained from Idemitsu Co.) and IDE118 (a blue fluorescent dopant obtained from Idemitsu Co.) (98:2, w / w) were vacuum-deposited on the HTL to form a 300 Å-thick EML.

[0176] Then, Alq 3 Vacuum deposited on the EML to form an ETL with a thickness of 300 Ȧ, LiF was vacuum deposited on the ETL to form an EIL with a thickness of 10 Ȧ, Al was vacuum deposited on the EIL to a t...

Embodiment 2

[0178] An organic light emitting device was prepared as in Example 1, except that Compound 43 was used instead of Compound 9 when forming the HIL.

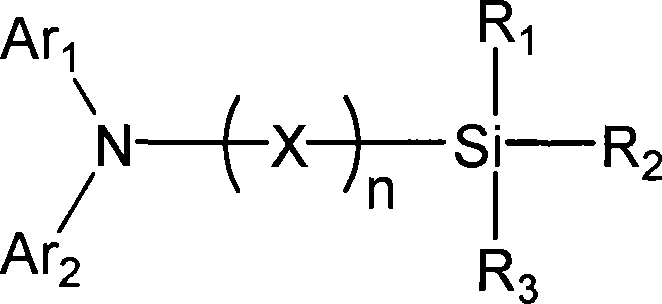

Embodiment 3

[0180] An organic light emitting device was prepared as in Example 1, except that Compound 44 was used instead of Compound 9 when forming the HIL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com