Method for preparing sheet porous structural ZnO nano powder

A technology of porous structure and nanopowder, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems that the synthesis of nano-ZnO with two-dimensional porous structure has not been reported in the literature, and achieve non-degeneration, low cost, and relatively low cost. The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Dissolve the zinc acetate dihydrate raw material in water to prepare a 0.1M zinc acetate solution, take 25mL of the zinc acetate solution in a flask, and add 25mL of a 0.2M urea solution dropwise under magnetic stirring to obtain a mixed solution.

[0031] (2) Place the flask of the mixed solution obtained in step (1) in a microwave oven, react at a power of 650W for 45min, and the reaction temperature is 75°C to obtain a cloudy solution.

[0032] (3) The turbid liquid obtained in step (2) is filtered, washed, and dried to obtain a basic zinc carbonate precursor.

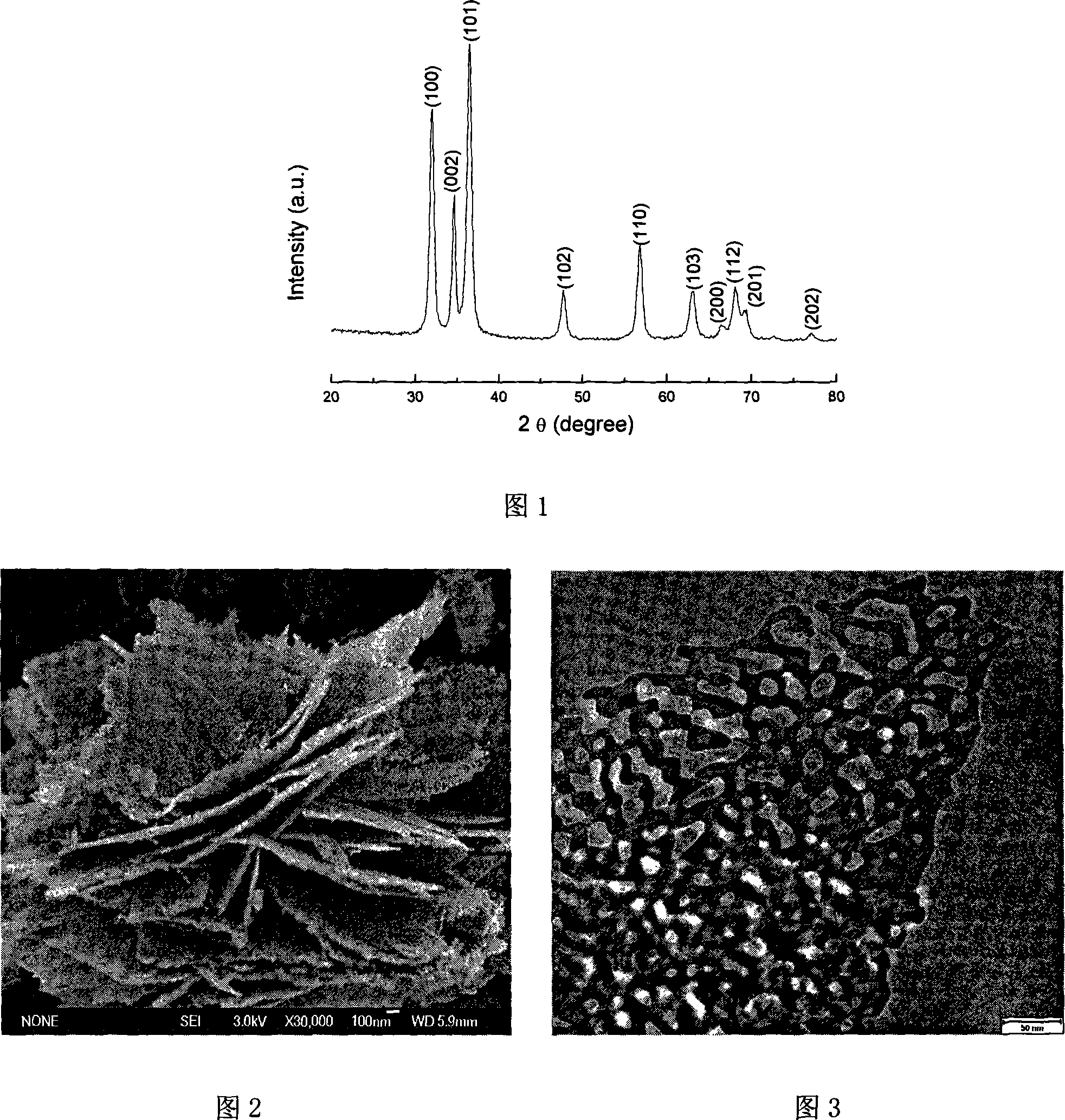

[0033] (4) The basic zinc carbonate precursor obtained in step (3) was placed in a muffle furnace at 450° C. for 2 h and calcined to obtain sheet-like porous ZnO nanopowder.

Embodiment 2

[0035] (1) Dissolve the zinc acetate dihydrate raw material in water to prepare a 0.3M zinc acetate solution, take 25mL of the zinc acetate solution in a flask, and add 25mL of a 0.4M urea solution dropwise under magnetic stirring to obtain a mixed solution.

[0036] (2) Place the flask of the mixed solution obtained in step (1) in a microwave oven, and react for 30 minutes at a power of 800W at a reaction temperature of 70° C. to obtain a cloudy solution.

[0037] (3) The turbid liquid obtained in step (2) is filtered, washed, and dried to obtain a basic zinc carbonate precursor.

[0038] (4) The basic zinc carbonate precursor in step (3) was placed in a muffle furnace at 500° C. for 2 h and calcined to obtain sheet-like porous ZnO nanopowder.

Embodiment 3

[0040] (1) Dissolve the zinc acetate dihydrate raw material in water to prepare a 0.5M zinc acetate solution, take 25mL of the zinc acetate solution in a flask, and add 30mL of a 0.6M urea solution dropwise under magnetic stirring to obtain a mixed solution.

[0041] (2) Place the flask of the mixed solution obtained in step (1) in a microwave oven, react for 30 minutes at a power of 850W, and the reaction temperature is 80° C. to obtain a cloudy solution.

[0042] (3) The turbid liquid obtained in step (2) is filtered, washed, and dried to obtain a basic zinc carbonate precursor.

[0043] (4) The basic zinc carbonate precursor in step (3) was placed in a muffle furnace at 550° C. for 2 h and calcined to obtain sheet-like porous ZnO nanopowder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com