Self-suction gas-liquid mixing impeller

A gas-liquid mixing and self-priming technology, which is applied in the direction of mixers, mixing methods, fluid mixers, etc., can solve the problems of poor gas-liquid mixing and dispersion, inability to increase air suction and suction and discharge at the same time, equipment vibration, etc. The problem is to achieve the effect of convenient adjustment of the air-bleeding volume, good air-water mixing effect, and increasing the length of the flow channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

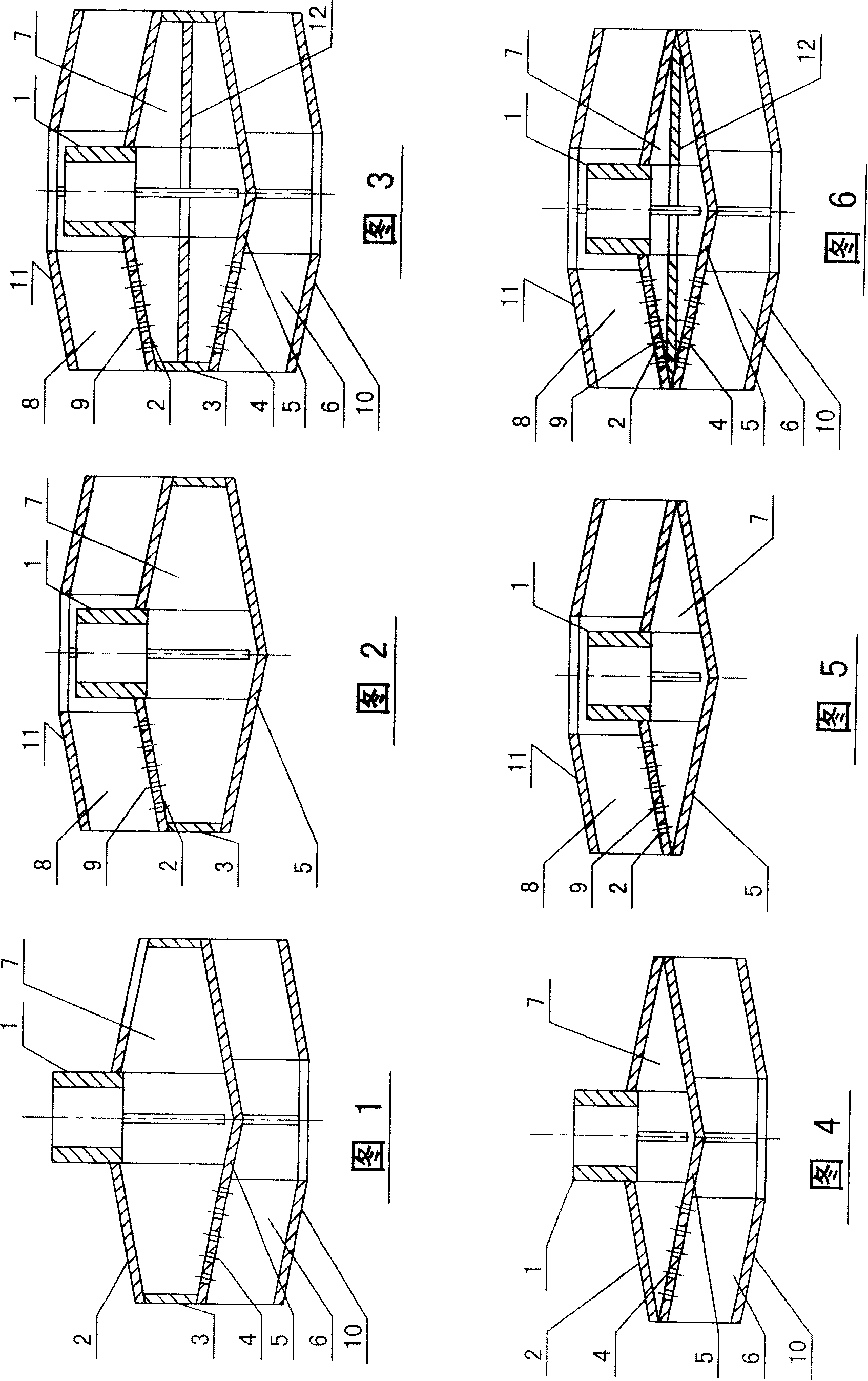

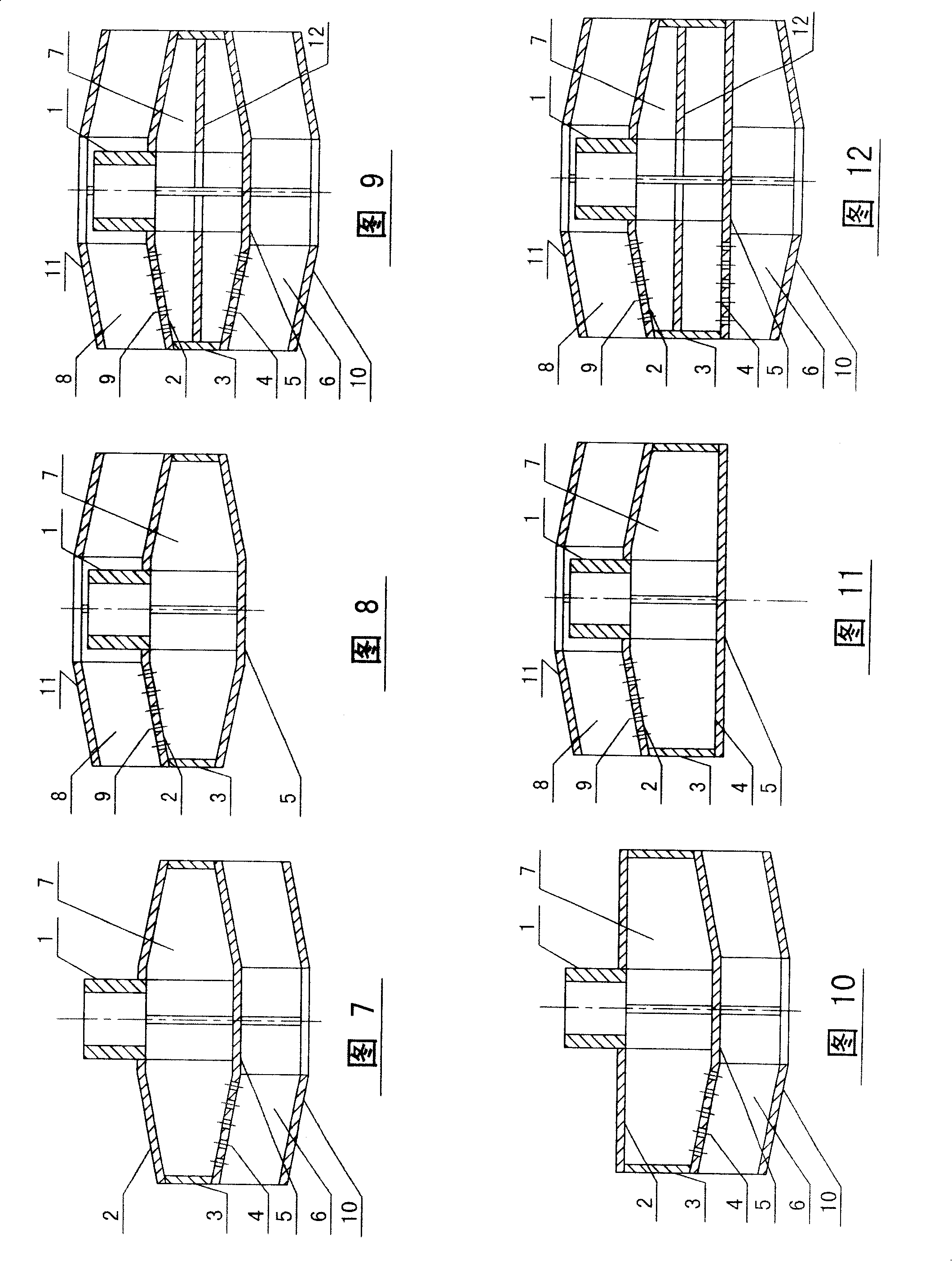

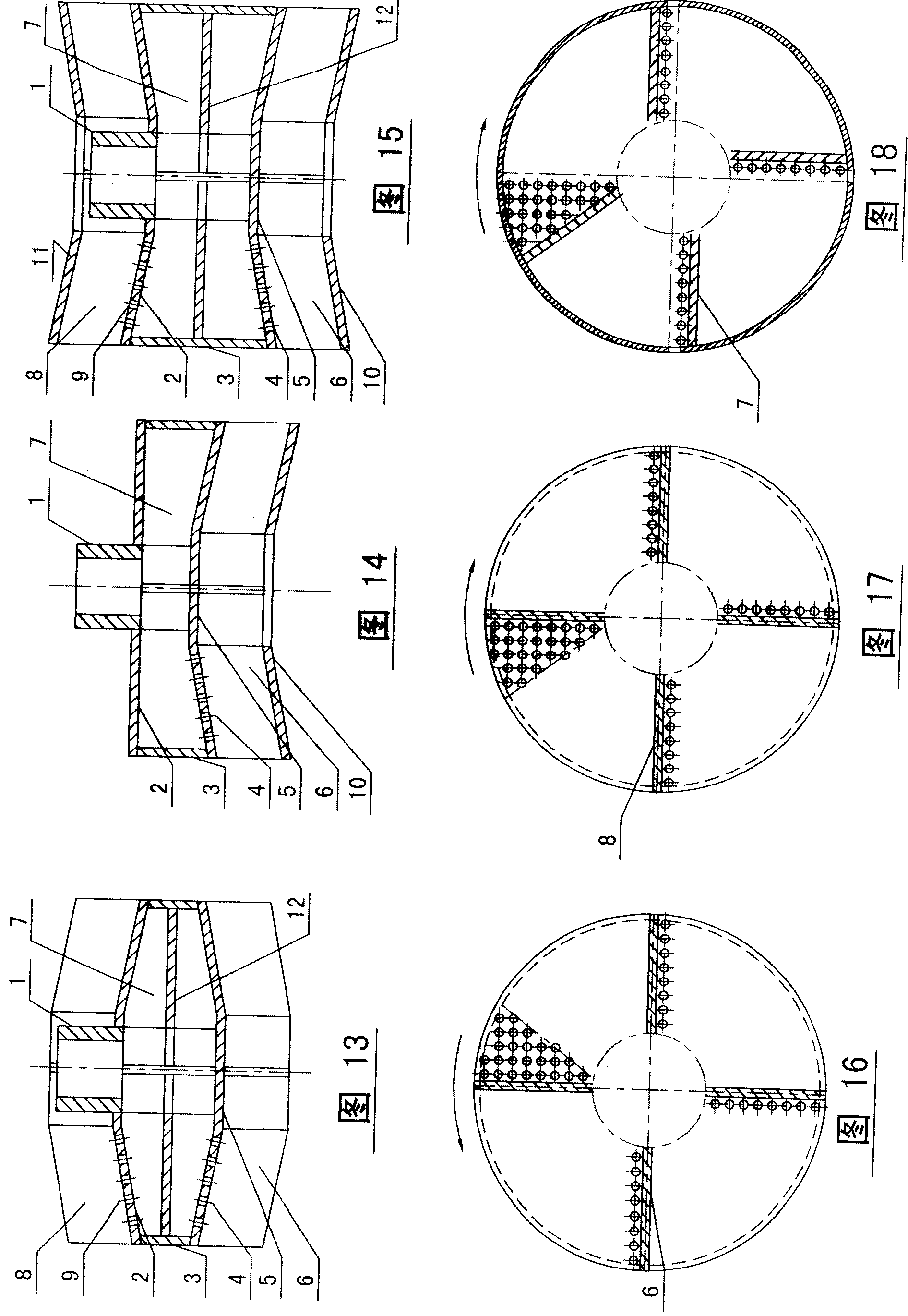

[0032] The structure and operation mode of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] As shown in Figures 1 to 15, the self-entrained gas-liquid mixing impeller of the present invention consists of a hollow coupling 1, an upper cover plate 2, a cylinder 3 (the cylinder 3 may not be provided, as shown in Figures 5 and 6), The lower cover plate 5, the lower guide vane 6 and / or the upper guide vane 8, wherein the upper cover plate 2, the cylinder body 3, and the lower cover plate 5 constitute the cylindrical hollow disk of the impeller; the lower guide vane 6 and the lower guide vane The air distribution holes 4 of the cover plate are arranged on the lower cover plate 5, and the air distribution holes 4 of the lower cover plate are located on the rear side of the lower guide vane 6; the upper guide vanes 8 and the air distribution holes 9 of the upper cover plate are arranged on the upper cover plate 2, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com