Method for producing organic concentration protein of soybean

A production method and a technology for concentrating protein, applied in the field of soybean protein production methods, can solve problems such as poor production safety and increased technical difficulty in production, and achieve benefits to human health, small production water consumption, and simple production processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

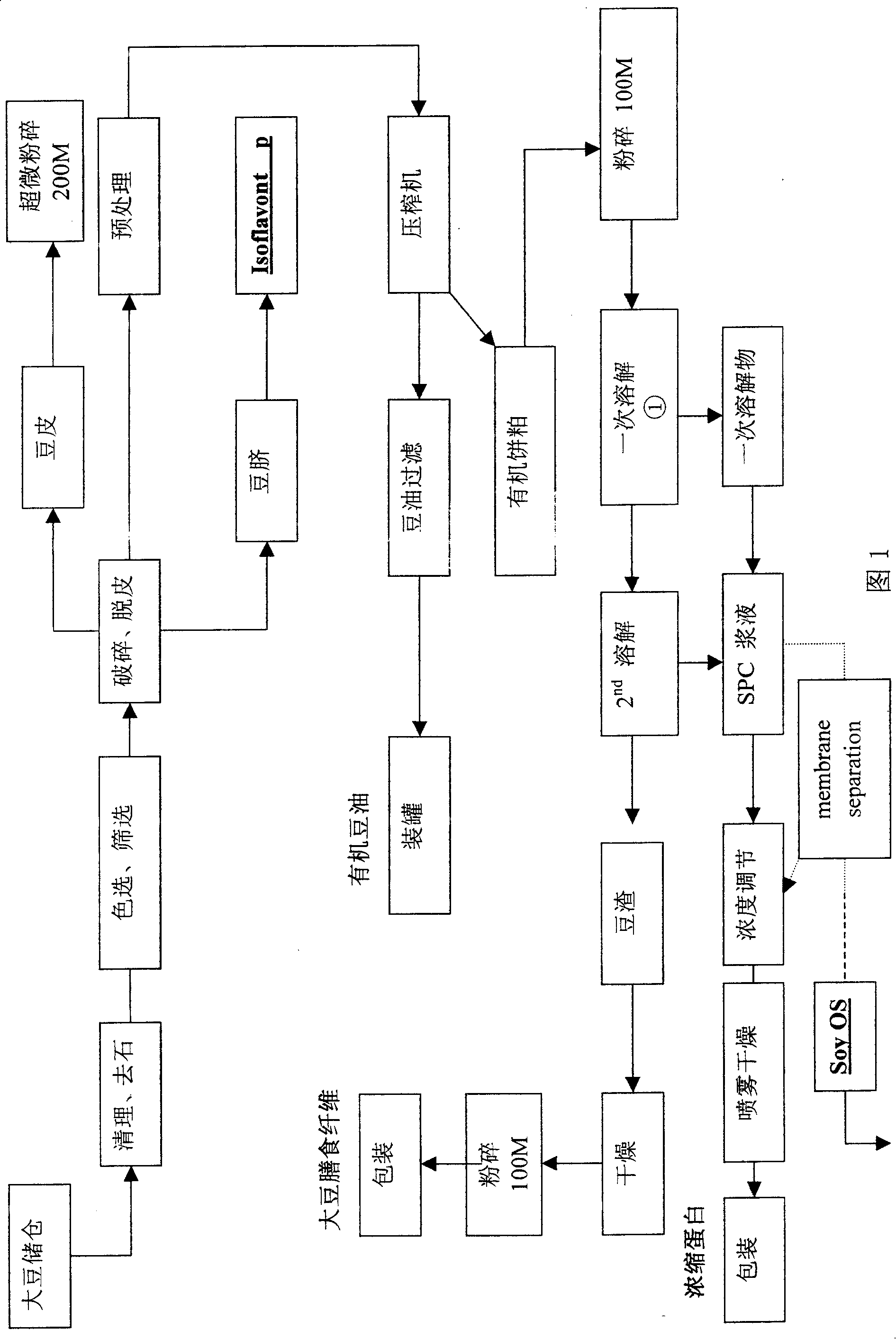

[0021] Embodiment 1, standard soybean protein production method.

[0022] 1. Degreasing soybeans and making soybean meal powder.

[0023] Soybeans from the soybean storage warehouse are measured and cleaned to remove light impurities, dust, stones, ironware, etc., and are sorted by a color sorter. Enter the skin, germ, and kernel separator, the skin and germ are collected separately and then output to the workshop, and the kernel is softened and rolled and heat-treated for 60-70 and then input into the press. The organic soybean oil obtained after being processed by a press machine is filtered, then filled into cans, labeled, boxed, and sold on the market; the obtained organic cake is used as a raw material of the present invention and crushed to 100 meshes.

[0024] 2. Soybean meal powder soaked in water.

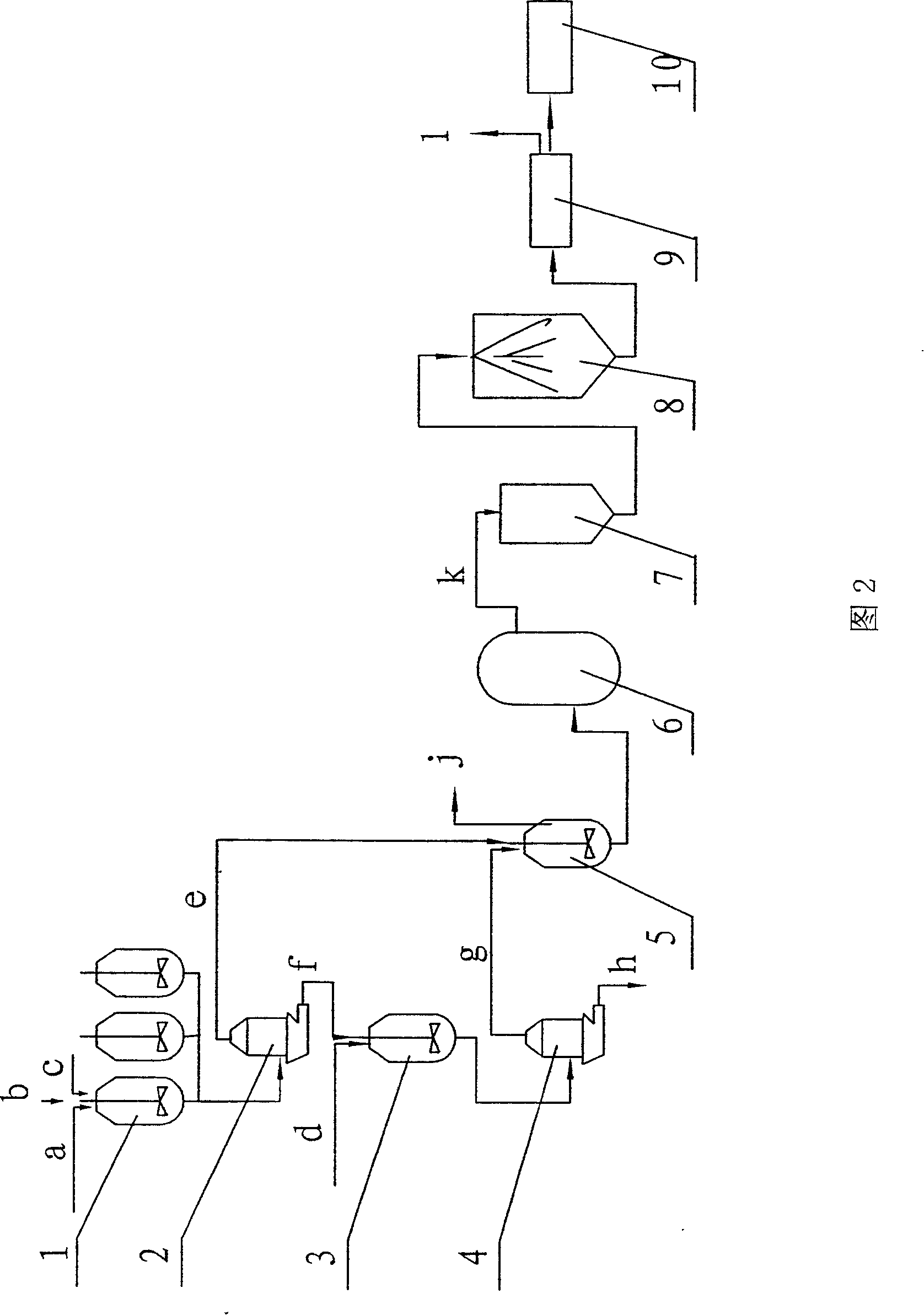

[0025] Add low-temperature soybean meal powder b in the first dissolution and leaching tank 1 with stirring and heating devices shown in Figure 2, add 7-9 times the weig...

Embodiment 2

[0038] Embodiment 2, the production method of beverage type soybean protein.

[0039] 1. Degreasing soybeans and making soybean meal powder.

[0040] With embodiment 1.

[0041] 2. Soybean meal powder soaked in water.

[0042] Add low-temperature soybean meal powder b in the first dissolution and extractor 1 shown in Figure 2, add 7-9 times the weight of soybean meal powder, water a at a temperature of 50°C, add 0.2-0.5% of the weight of soybean powder and edible salt and soybean powder weight 0.2-0.5% of baking soda c. Stir and heat to 75-90°C, keep warm for 15-20 minutes, if defoamer is required, follow GMP.

[0043] 3. Separation.

[0044] With embodiment 1.

[0045] 4. Secondary separation.

[0046] With embodiment 1.

[0047] 5. Concentration.

[0048] With embodiment 1.

[0049] 6. Add enzyme

[0050] The concentrated solution k is put into a tank with heating and stirring, the temperature is controlled at 45-60° C., papain is added according to the weight of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com