Gasoline engine electric-starting flywheel

A gasoline engine and electric starting technology, which is applied to the starting of the engine, the starting of the motor for the engine, and engine components, etc., can solve the problems of large rotational inertia, pollution of the processing environment, and large processing allowance, so as to reduce the rotational inertia and reduce the The effect of simple manufacturing cost and processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

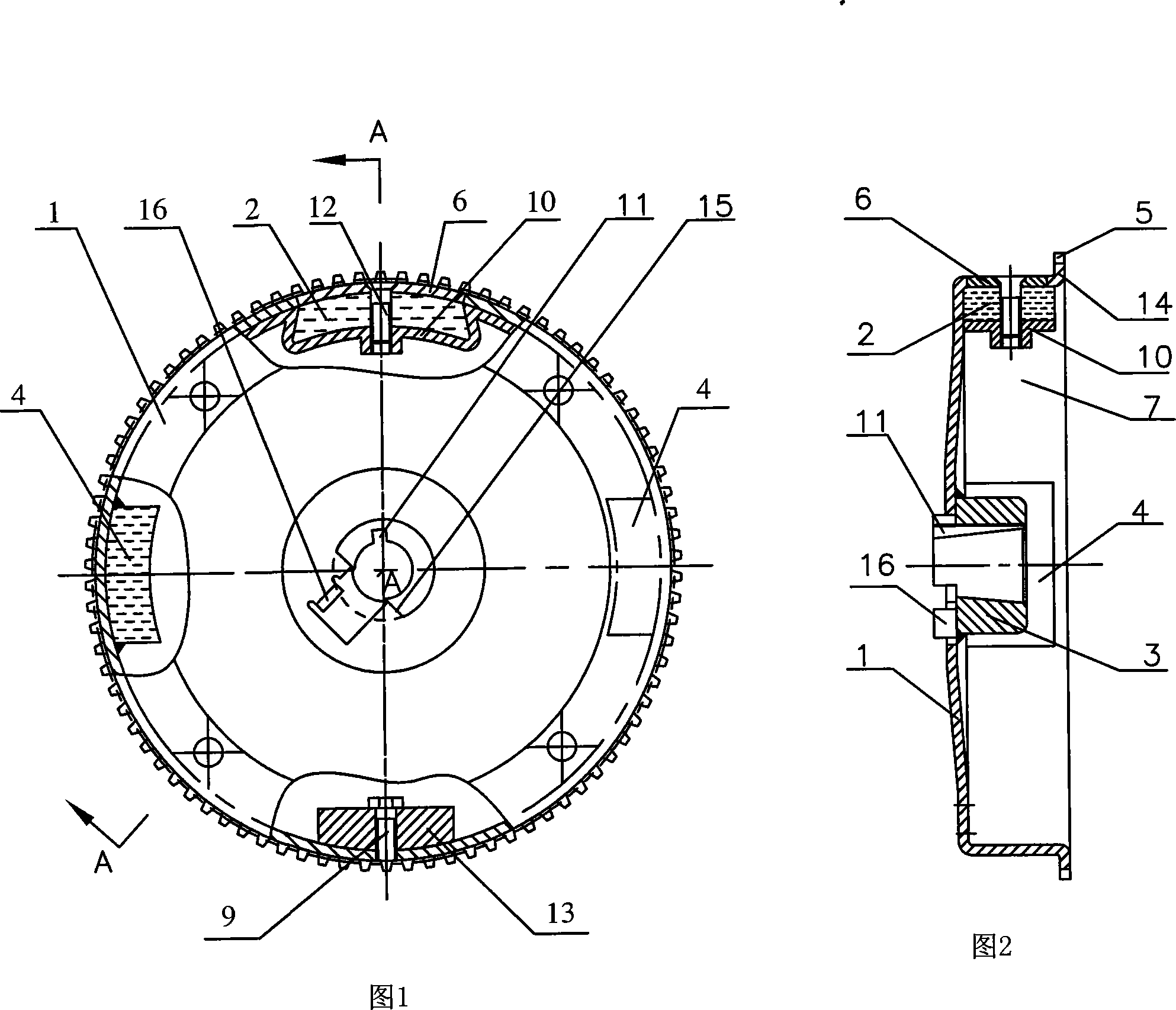

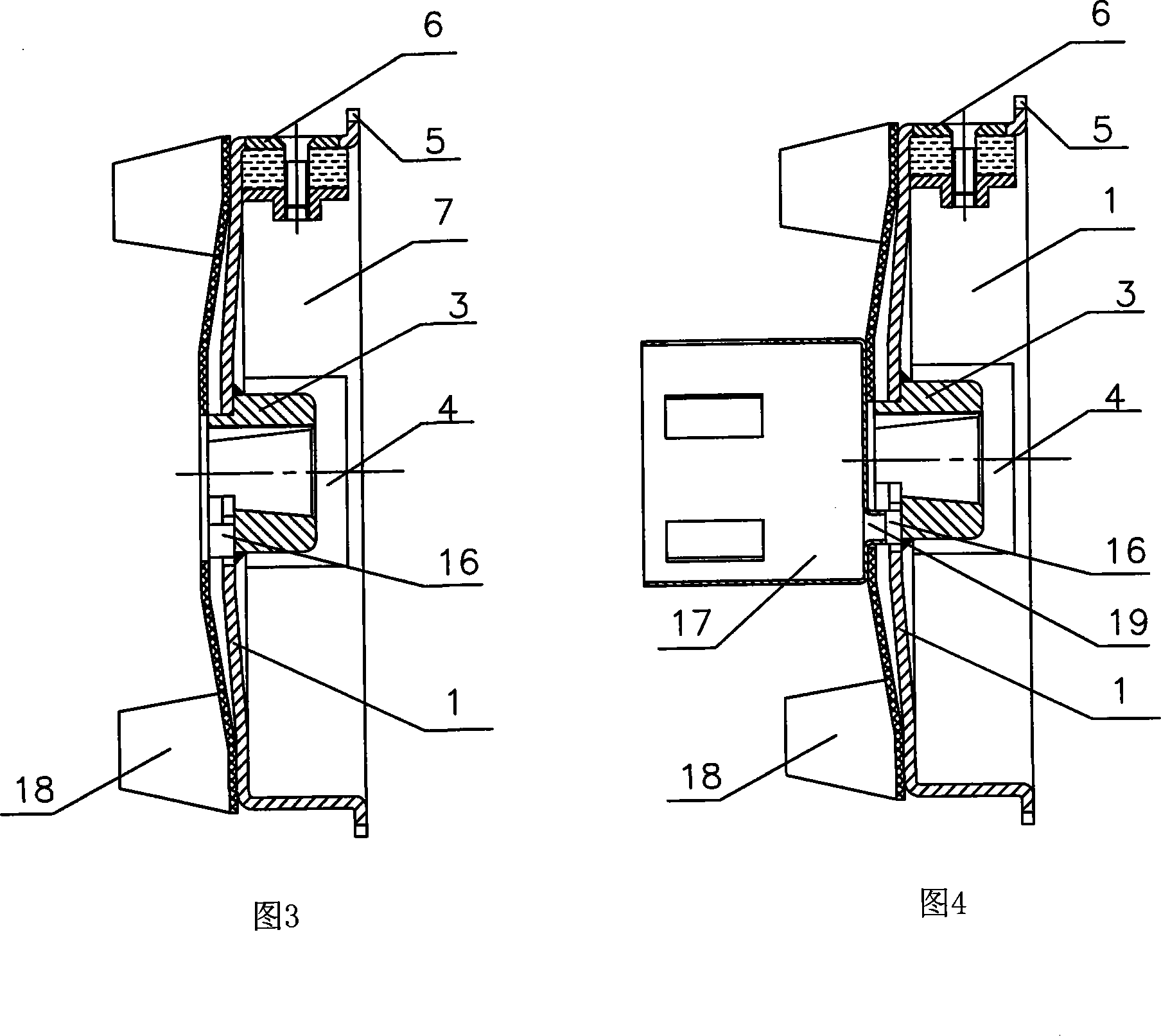

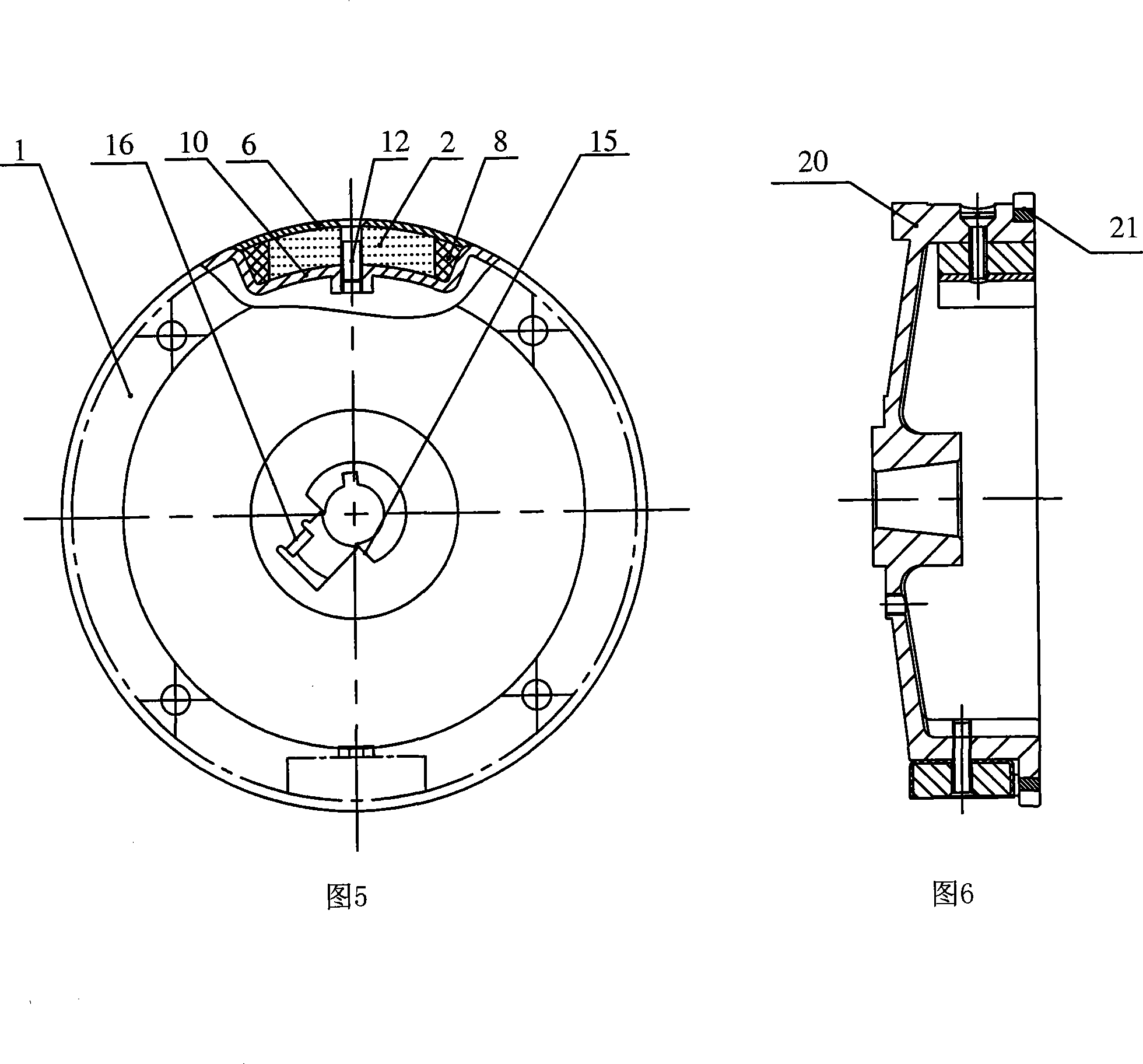

[0015] Referring to Fig. 1 to Fig. 3, the flywheel disc 1 of the electric start flywheel of the present invention is a flywheel disc formed by deep drawing and stamping of a steel plate with a cavity 7 and an electric start driven tooth 5. The driven teeth 5 are located on the flange 14 of the ring flywheel that is turned and extended from the mouth of the cavity 7 of the flywheel 1. The flange 14 is integrated with the flywheel 1 and is perpendicular to the axis of the flywheel 1. The driven teeth 5 are punched and formed on the circumference of the flange 14 . A mouth is provided on the peripheral surface of the flywheel disc 1, and a bracket 10 for fixing the outer magnetic steel is provided in the concave cavity of the flywheel disc 1 corresponding to the mouth. The bracket 10 is bent into a groove and fixedly connected to the inner peripheral wall of the flywheel disc 1 , and the same effect can be achieved by welding or riveting on the inner peripheral wall of the flywhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com