Heat-insulation water-sealing groove for coke dry quenching furnace and preparation method thereof

The technology of hot water sealing tank and dry quenching coke oven is applied in the field of coal chemical industry. , high deformation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

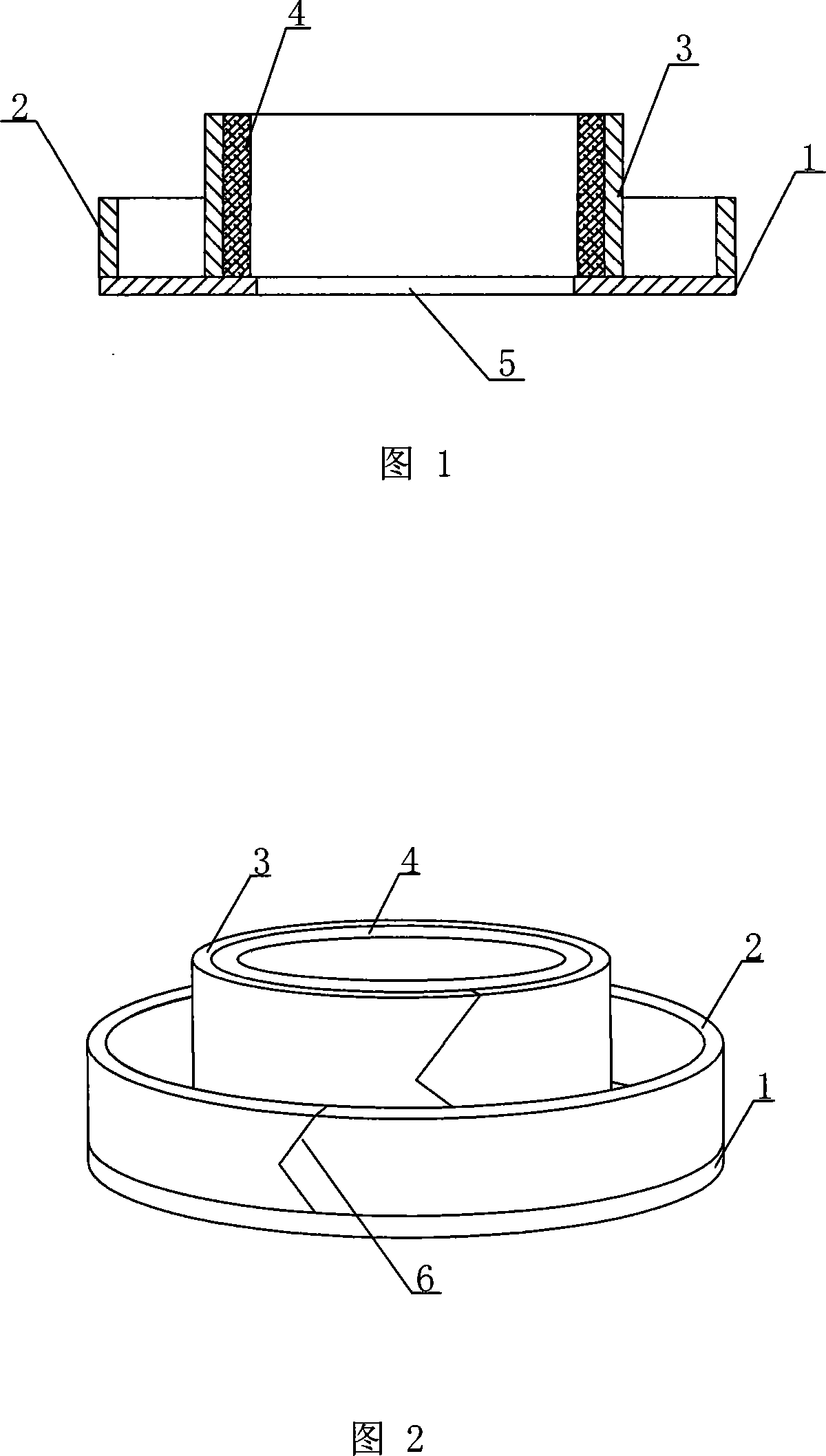

[0028] Embodiment 1 As shown in Figure 1, the metal body of the heat-insulating heat-seal tank for CDQ coke ovens is divided into three parts: the inner skirt 3, the outer skirt 2 and the bottom plate 1, and a layer is arranged on the inner side of the inner skirt Casting layer 4 of fire-resistant and heat-insulating material.

[0029] The center of the bottom plate 1 is provided with a gas through hole 5, the inner skirt 3 is welded and fixed on the bottom plate on the outer edge of the gas through hole, the outer ring of the inner skirt is welded with an outer skirt 2, and the inner skirt and the outer skirt are cylindrical The structure, the inner skirt and the outer skirt are welded and fixed concentrically, the bottom plate, the inner skirt and the outer skirt are all ordinary A3 hot-rolled low-carbon steel plates, the thickness of which is about 3-5mm, and the inner side of the inner skirt is fixed. The refractory and heat-insulating casting layer 4 is a refractory and h...

Embodiment 2

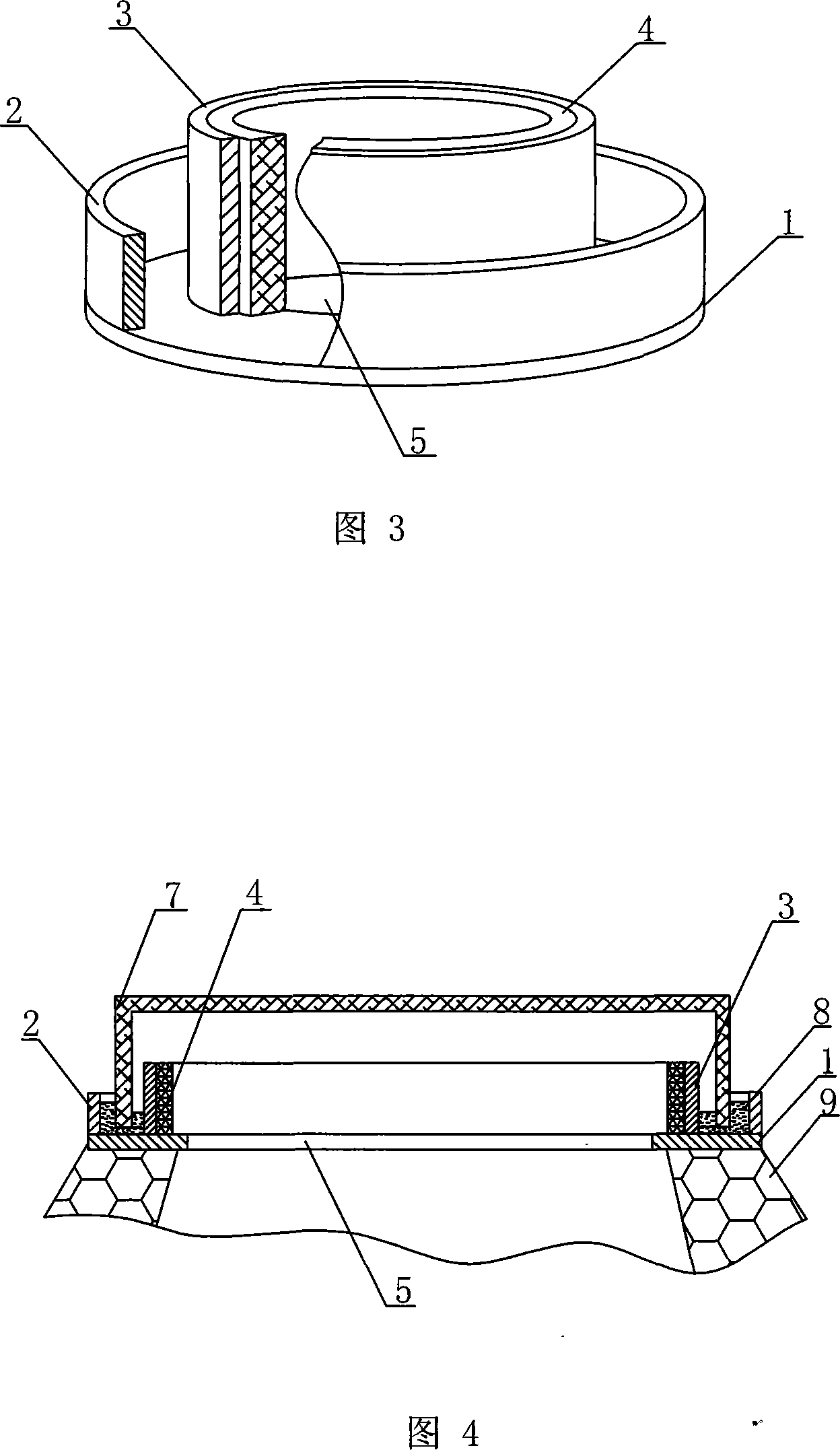

[0032] Embodiment 2 As shown in Figure 2 and Figure 3, the metal body of the heat-insulating water seal tank for CDQ coke ovens is divided into three parts: the inner skirt 3, the outer skirt 2 and the bottom plate 1, and the inner side of the inner skirt A pouring layer 4 of fire-resistant and heat-insulating material is arranged close to it.

[0033] The center of the bottom plate is cut with a gas hole, the bottom plate on the outer edge of the gas hole is welded and fixed with an inner skirt, and the outer ring of the inner skirt is welded with an outer skirt, and the inner skirt and the outer skirt are welded by ordinary carbon steel plates The cylindrical structure, the inner skirt and the outer skirt are concentrically welded and fixed on the bottom plate. The bottom plate, the inner skirt and the outer skirt are made of ordinary carbon steel plates with a thickness of about 8-10mm. The fire-resistant and heat-insulating casting layer fixed on the inner side of the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com