Comprehensive utilization technique and system for soft-burned dolomite fines

A technology for lightly burning dolomite and fine powder, applied in the field of technology, can solve problems such as environmental pollution and waste of limited resources, and achieve the effects of reducing investment and energy consumption, saving resources, and ensuring uniformity and smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

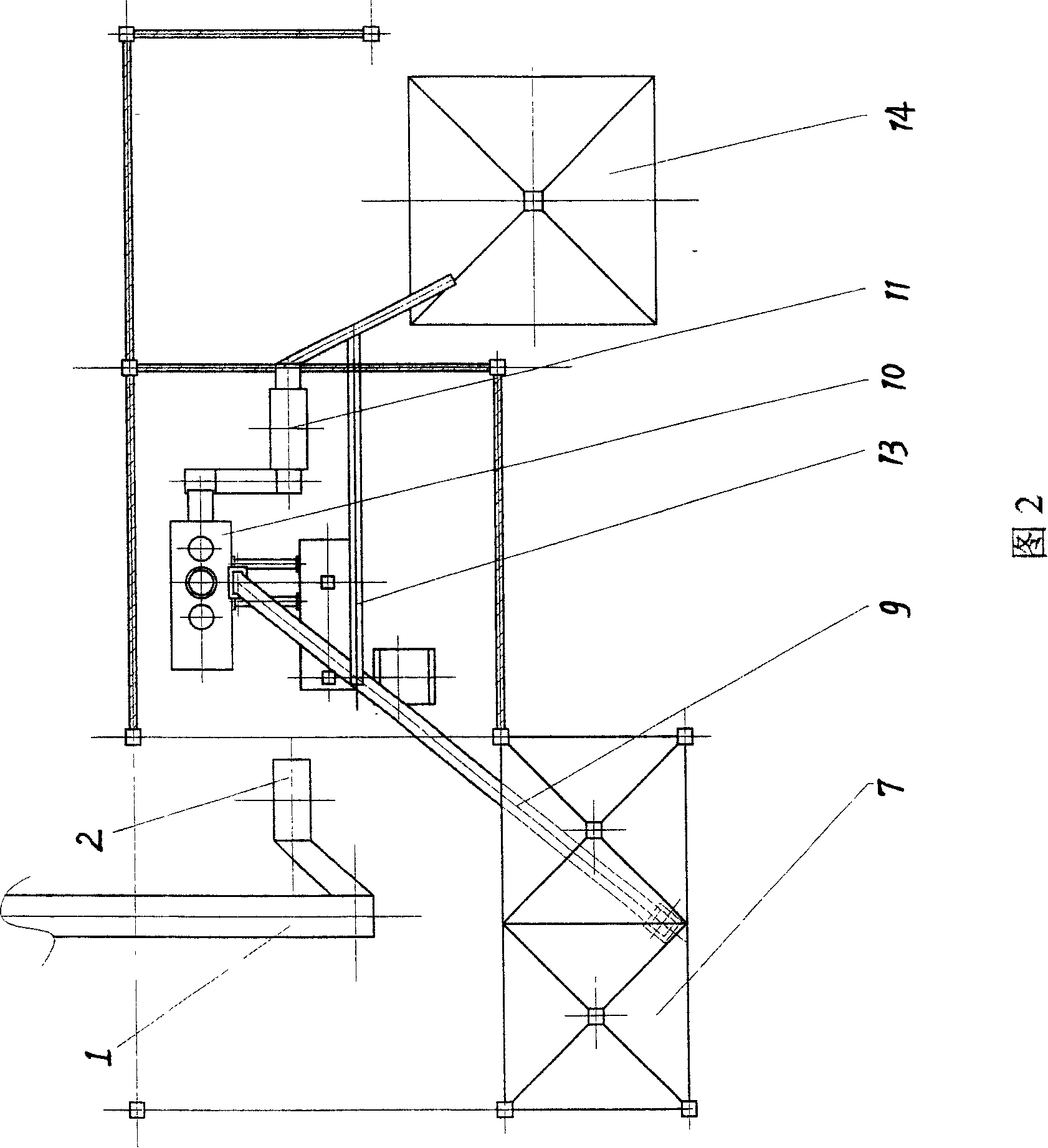

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

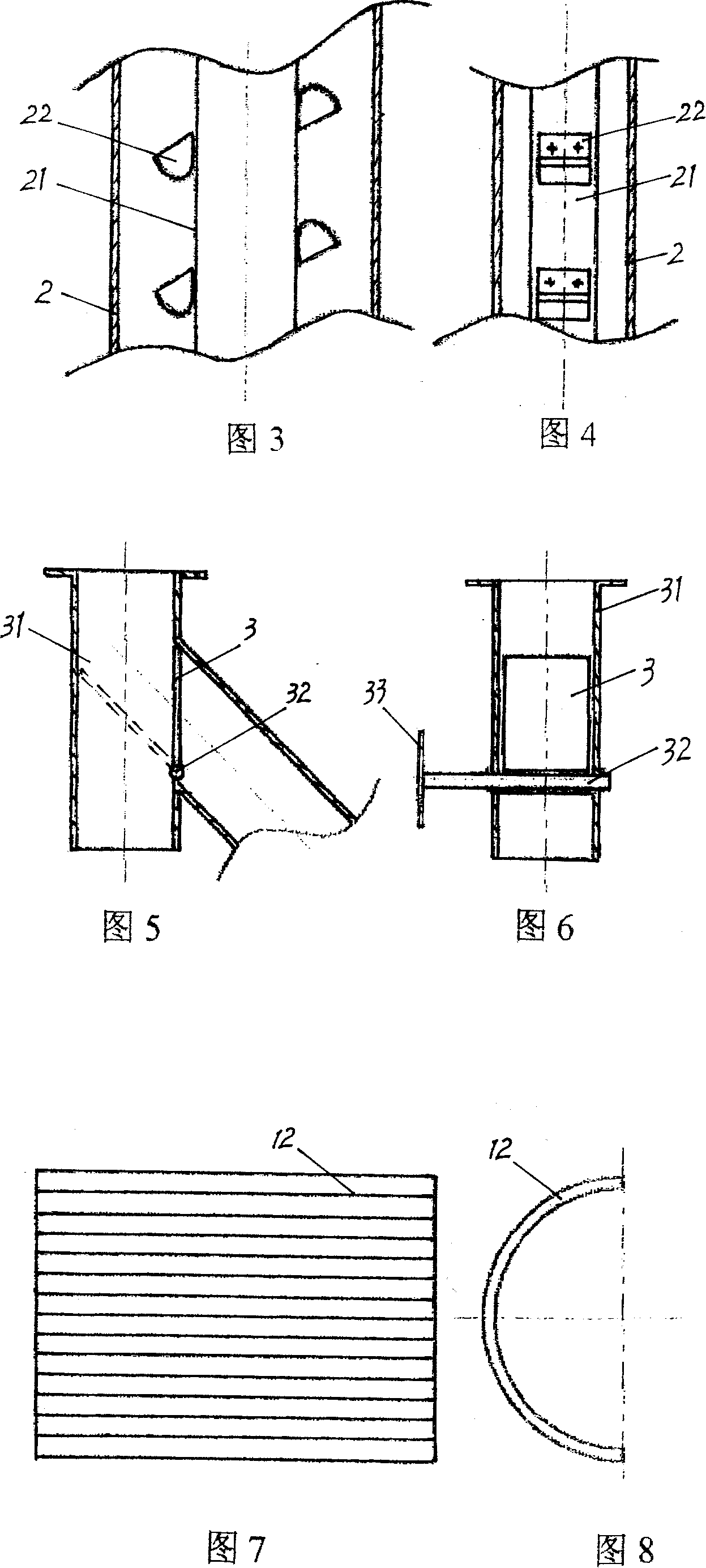

[0020] The conveyor 1 below the discharge port of the shaft kiln is connected with the hoist 2 through a slide pipe, and the hoist 2 is a chain hoist, and the chain 21 inside is provided with hoppers 22 at intervals, as shown in Fig. 3 and Fig. 4 , and the hoist 2 exits The material opening is connected with the three-fork feeding pipe 31 and the tube screen 4 with the flap 3 on it, the upper end of the flap 3 is suspended, and the lower end is connected with the pipe wall through the hinge shaft 32, and the other end of the hinge shaft 32 is extended to the outside of the pipe and connected with the handle 33 , the operating handle 33 can make the turning plate 3 rotate around the hinge shaft 32, as shown in Fig. 5 and Fig. Link to each other with the powder mixing bin 7 through the chute, the bin wall above the outlet of the powder mixing bin 7 is provided with a min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com