Corrosion-resisting clogging-proof overcritical water oxidization reactor

A supercritical water oxidation and reactor technology, which is applied in the oxidation water/sewage treatment and other directions, can solve the problems of accidents, decreased heat transfer efficiency, reactor or pipeline blockage, etc., and achieves convenient production, disassembly and assembly, and simple structure. , to ensure the effect of stable and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

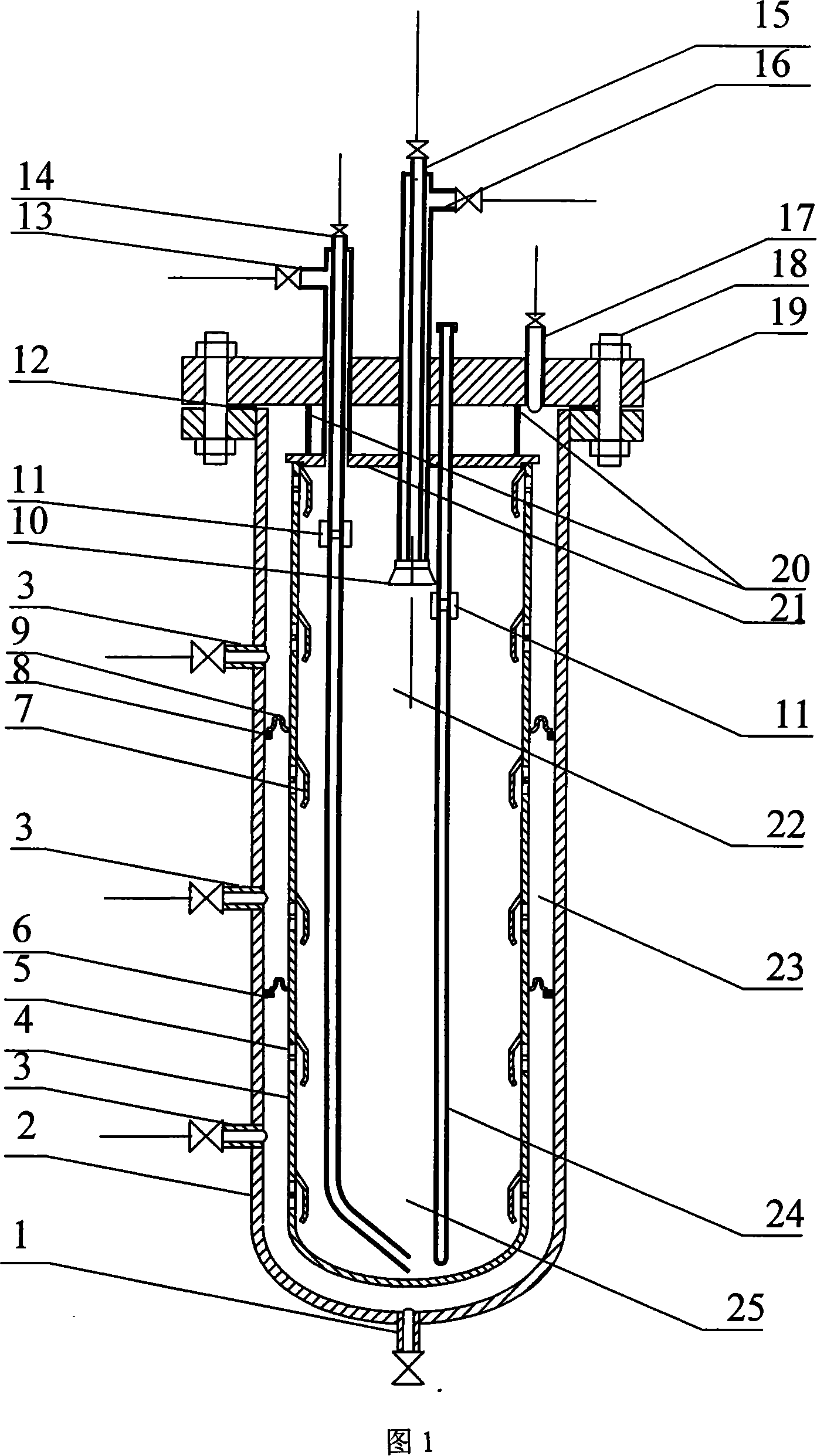

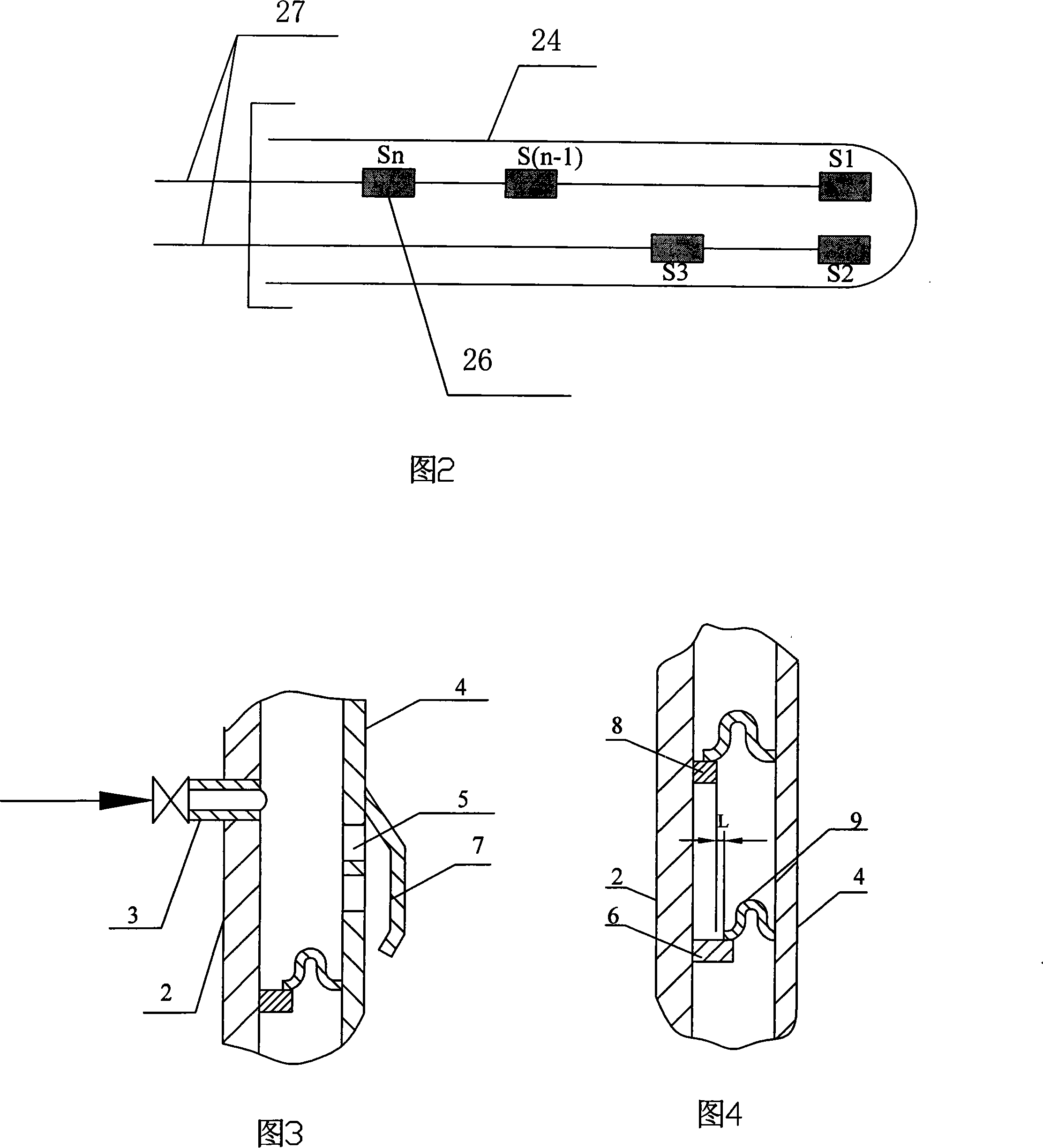

[0026] A specific embodiment of the present invention is given below in conjunction with each accompanying drawing.

[0027]The reactor in Fig. 1 is an inner and outer double cylinder structure, 2 is the outer cylinder of the reactor, and 4 is the inner cylinder of the reactor. The outer cylinder cover 19 and the inner cylinder upper cover 21 are fixedly connected as a whole through the bracket 20, and the inlet and outlet pipelines 13, 14, 15, 16 and the temperature measuring envelope 24 are directly welded on the inner cylinder upper cover and the outer cylinder cover. An oxygen inlet pipe 15 and a liquid inlet pipe 16 of a casing structure are arranged at the central line of the reactor, and a nozzle device 10 is added at the bottom of the casing. The gas product outlet pipe 13 and the liquid product outlet pipe 14 also adopt a casing structure. The liquid product outlet pipe 14 and the temperature measuring jacket 24 are respectively inserted into the bottom of the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com