Low nickel-chrome-molybdenum alloy cast iron wear-resistant material for profiled bar straightening roller

A nickel-chromium-molybdenum alloy and wear-resistant material technology is applied in the field of low-nickel-chromium-molybdenum alloy cast iron wear-resistant materials, which can solve the problems of high one-time service life and inconsistent production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

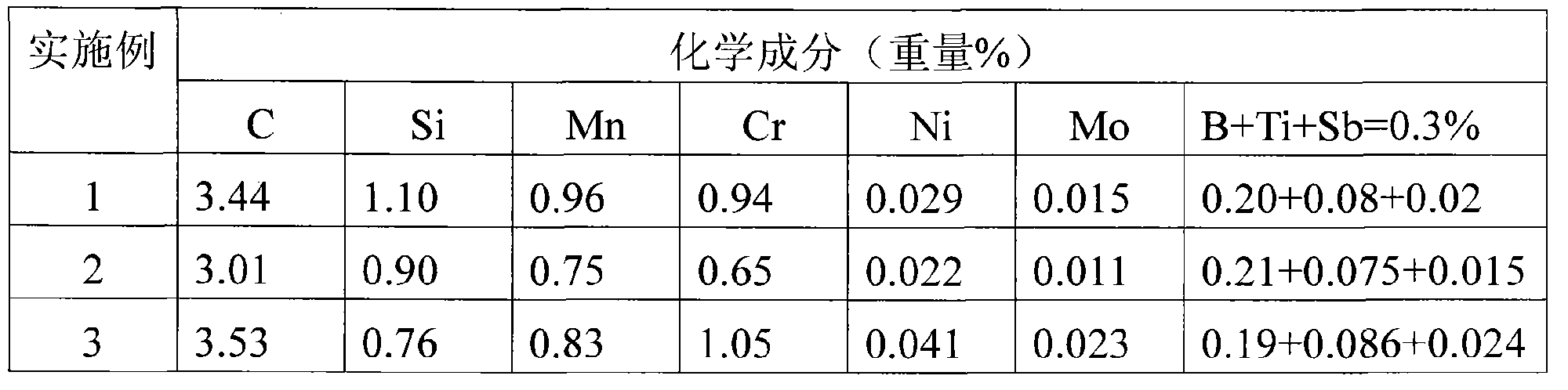

Embodiment 1

[0006] Embodiment 1: The sample of the present invention has been made into 10# angle steel straightening rolls and put on trial at the No. 3 Steel Rolling General Plant of Maanshan Iron and Steel Co., Ltd., and its chemical composition is shown in Table 1. The depth of the cast iron white area is more than 20mm, and the hardness of the working surface of the roll body is within the range of HRc58-63.

[0007] During the trial, it was used together with the nickel-chromium-molybdenum infinite chilled cast iron straightening roller provided by a factory in Jiangsu. After straightening 13433 tons of 10# angle steel, the two types of straightening rollers were found to be uniformly worn during off-line inspection. After the same turning depth of 2.25mm, 10821 tons of 10# angle steel were rolled on the line again.

Embodiment 2

[0008] Embodiment 2: The sample of the present invention has been made into 8# channel steel straightening roller and is still on trial at Mashan Iron and Steel Co., Ltd., and its chemical composition is shown in Table 1. The hardness of the working surface of the roll body is in the range of HRc55-60, and the comprehensive service life of the two rollings is 23,500 tons.

Embodiment 3

[0009] Embodiment 3: The sample of the present invention has been made into a 350×175 small H-shaped steel straightening roll, which is also tested in Maanshan Iron and Steel Co., Ltd., and its chemical composition is shown in Table 1. The hardness of the working surface of the roll body is in the range of HRc57-62, and the comprehensive service life of the two rollings is 24,100 tons.

[0010] The practical trial of the invention at the production site proves that its service life is not lower than that of the commonly used nickel-chromium-molybdenum infinite chilled cast iron straightening rollers, and can effectively reduce the cost of producing shaped steel.

[0011] Table 1 Chemical composition of low-nickel-chromium-molybdenum alloy cast iron wear-resistant materials

[0012]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com