Environment-friendly type oil refining method and oil refining device employing the method

An oil refining device, an environmentally friendly technology, applied in the field of oil refining with waste plastics and waste rubber, can solve the problems of waste gas without treatment, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

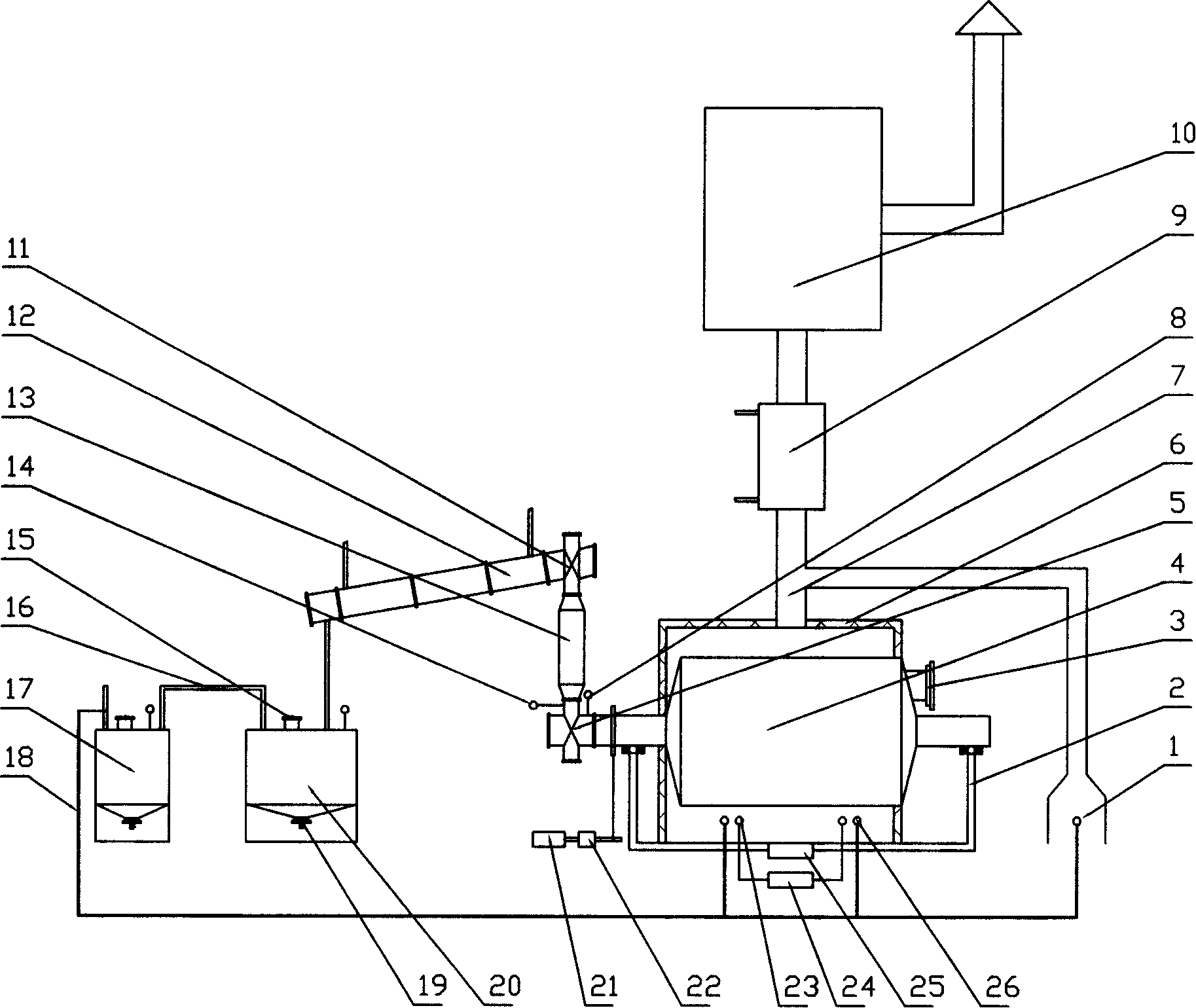

[0013] Embodiment 1: As shown in the accompanying drawing, the oil refining device, the rotary processor body 4 is installed on the rotary bracket 2, the motor 21 is connected with the rotary processor body through the reducer 22, and the rotary processor body 4 is located in the heat preservation shell 6 A fuel burner 23 and a first gas burner 26 are installed below the rotary processor body 4 , and the fuel burner 23 is supplied with oil from the fuel tank 24 . There are feed inlet 3 and steam outlet on the rotary processor body 4, and the steam outlet is connected with the gas distribution bag 13 through the four-way Unicom pipe 5, and a pressure gauge 14 and a temperature gauge 8 are installed at the steam outlet, and the gas distribution bag The outlet of 13 is connected with the inlet of the oil passage condenser 12 through the communication pipe 11, and the outlet of the oil passage condenser 12 is connected with the oil-water separator 20. The oil-water separator 20 is ...

Embodiment 2

[0017] Embodiment 2: In this embodiment, potassium hydroxide is used as the dissolving agent, and the addition of potassium hydroxide is 5 / 1000 of the total weight of waste rubber and waste plastics. The temperature is lowered to 10 DEG C, and others are the same as in Example 1.

Embodiment 3

[0018] Embodiment 3: In this embodiment, sodium hydroxide is used as the dissolving agent, and the addition of sodium hydroxide is 4 / 1000 of the total weight of waste rubber and waste plastics. The temperature is lowered to 20° C., and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com