Revolving cracking machine

A technology of crushers and racks, applied in the direction of grain processing, etc., to achieve the effect of simplifying the crushing process, reducing the type and quantity, and improving the efficiency of crushing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

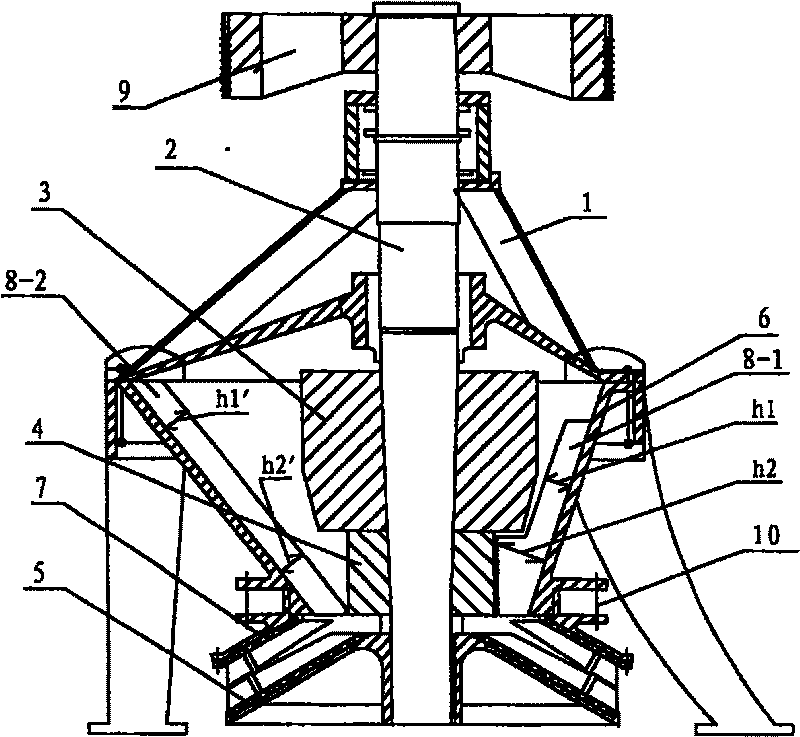

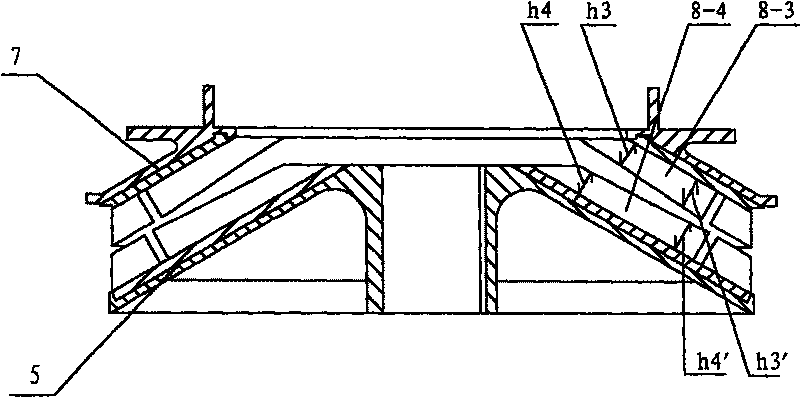

[0034] The structure of the embodiment of this technical solution, through Figure 1 ~ Figure 3 To represent.

[0035] exist figure 1 Among them, this circular cutting and rubbing crusher includes a drive shaft 2 vertically arranged on the frame 1, a rotating grinding head connected to the driving shaft and a groove plate fixed on the frame, and the gap between the grinding head and the groove plate Constitute the material crushing cavity.

[0036] Its rotating grinding head is made of big breaking wheel 3, middle breaking wheel 4 and lower cone disc 5.

[0037] Further, the big broken wheel is a combination of a cylinder with an upper part and a positive and inverted truncated cone at the lower part, or an inverted truncated cone.

[0038] The middle breaking wheel is a cylinder, and the lower cone is an upright truncated cone.

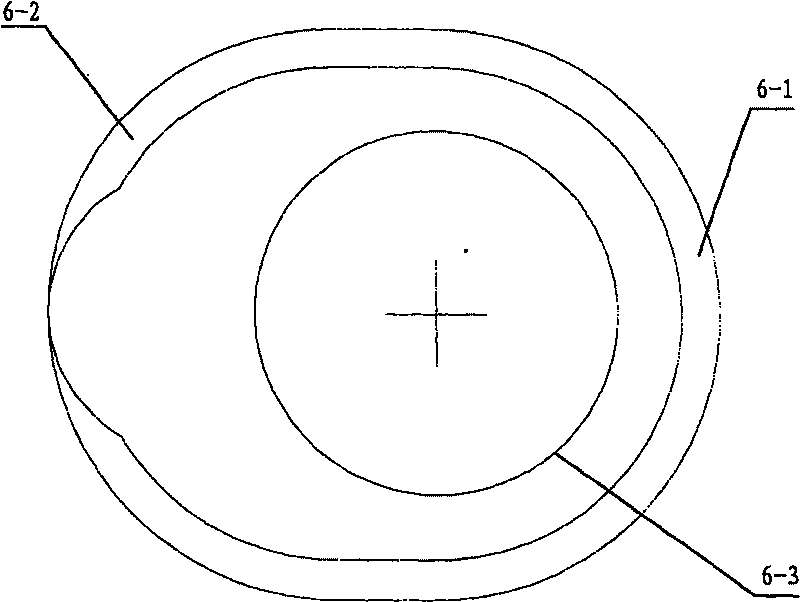

[0039] The slot plate corresponding to the positions of the large broken wheel and the middle broken wheel constitutes a working chamber 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com