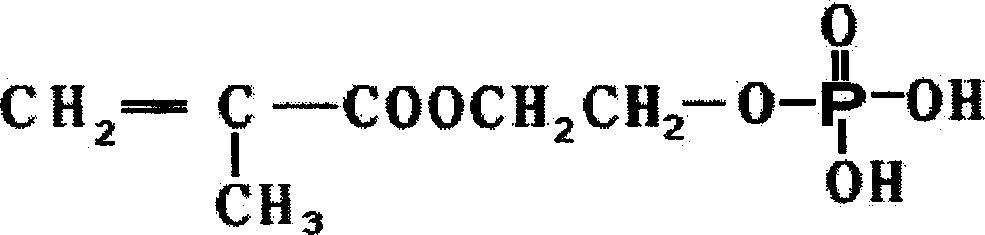

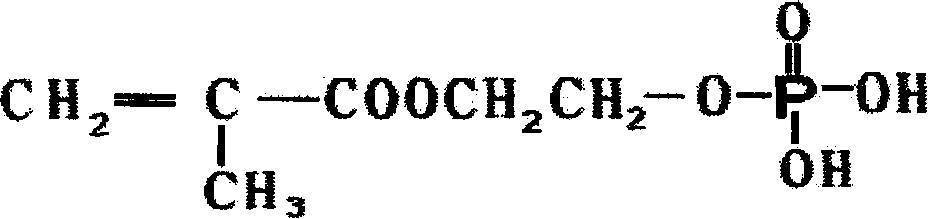

Methacrylic acid phosphoric acid ester slushing polymerisable emulsifier and its preparing method

A technology of phosphate methacrylate and polymeric emulsifier, which is applied in chemical instruments and methods, anti-corrosion coatings, chemical/physical processes, etc., can solve environmental pollution and other problems, achieve faster film forming speed, stable production process, and improve water resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

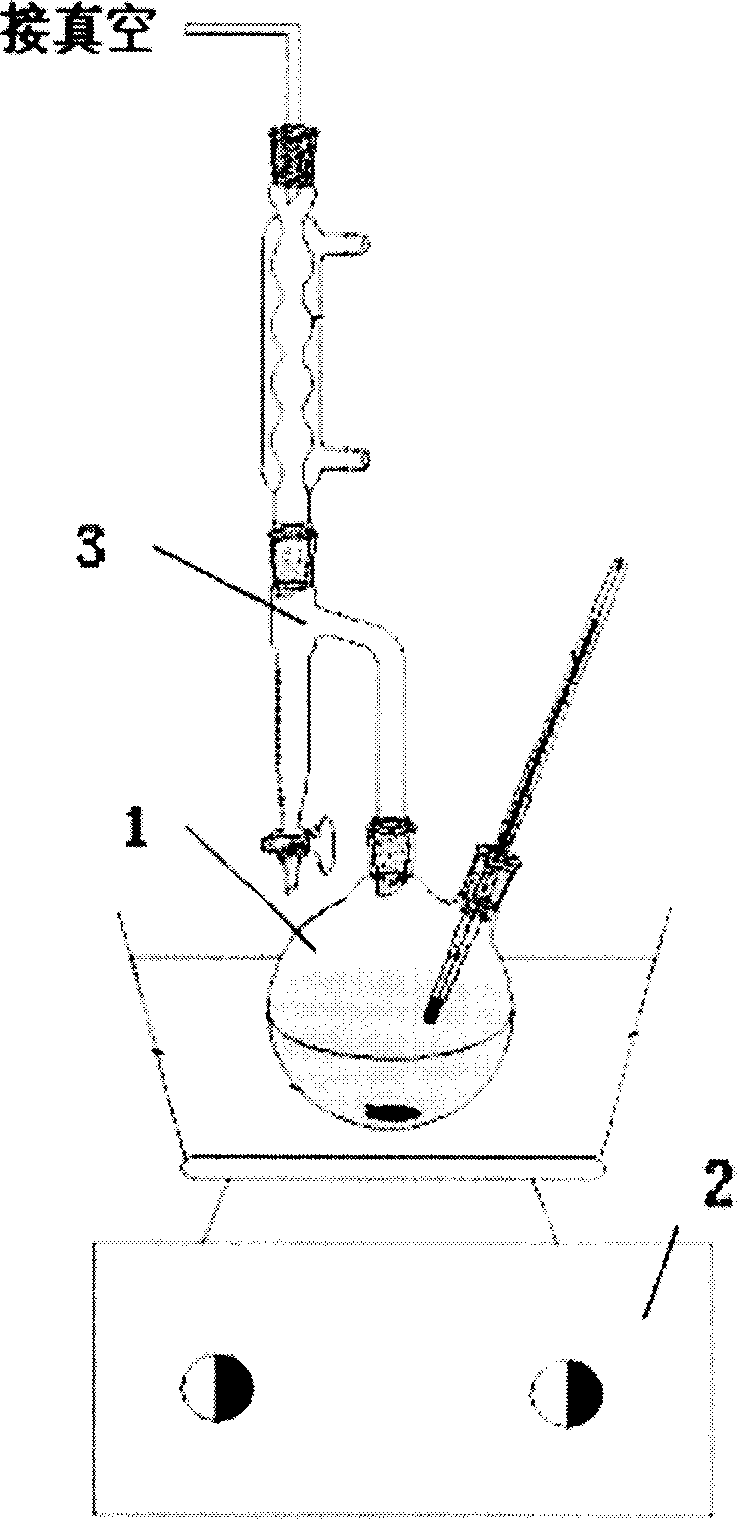

[0023] like figure 1 As shown, in the two-necked flask 1, 132 grams of methacrylate-β-hydroxyethyl ester, 98 grams of 98% phosphoric acid, and 20 grams of toluene were mixed, and 0.125 grams of hydroquinone was added, and the system was decompressed so that the system pressure reached 0.06 MPa, start the constant temperature magnetic stirrer 2 to stir (300r / min) and be heated to 60 ℃, constantly the water that is generated is separated by the water separator 3, obtain solution A after reacting 4h (at this moment, conversion rate reaches 60%), in The solvent toluene in the solution A was distilled off under reduced pressure at 0.07Mpa and recovered. After the reaction was completed, the product was taken out and sealed for packaging.

Embodiment 2

[0025] like figure 1 As shown, in the two-necked flask 1, 132 grams of methacrylate-β-hydroxyethyl ester, 98 grams of 98% phosphoric acid, and 20 grams of toluene were mixed, and 0.125 grams of hydroquinone was added, and the system was decompressed so that the system pressure reached 0.07 MPa, start the constant temperature magnetic stirrer 2 to stir (300r / min) and be heated to 60 ℃, constantly the water that is generated is separated by the water separator 3, obtain solution A after reacting 5h (conversion rate reaches 70%) at this moment, in The solvent toluene in the solution A was distilled off under reduced pressure at 0.08Mpa and reclaimed. After the reaction was completed, the product was taken out and sealed for packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com