Repair joint of photoelectric composite sea cable

A photoelectric composite and optical cable joint technology, which is applied in the direction of optical fiber/cable installation, clamping/spring connection, fiber mechanical structure, etc., can solve the problems of inability to connect submarine cables, etc., and achieve simple structure, reliable operation, and simple installation and operation procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

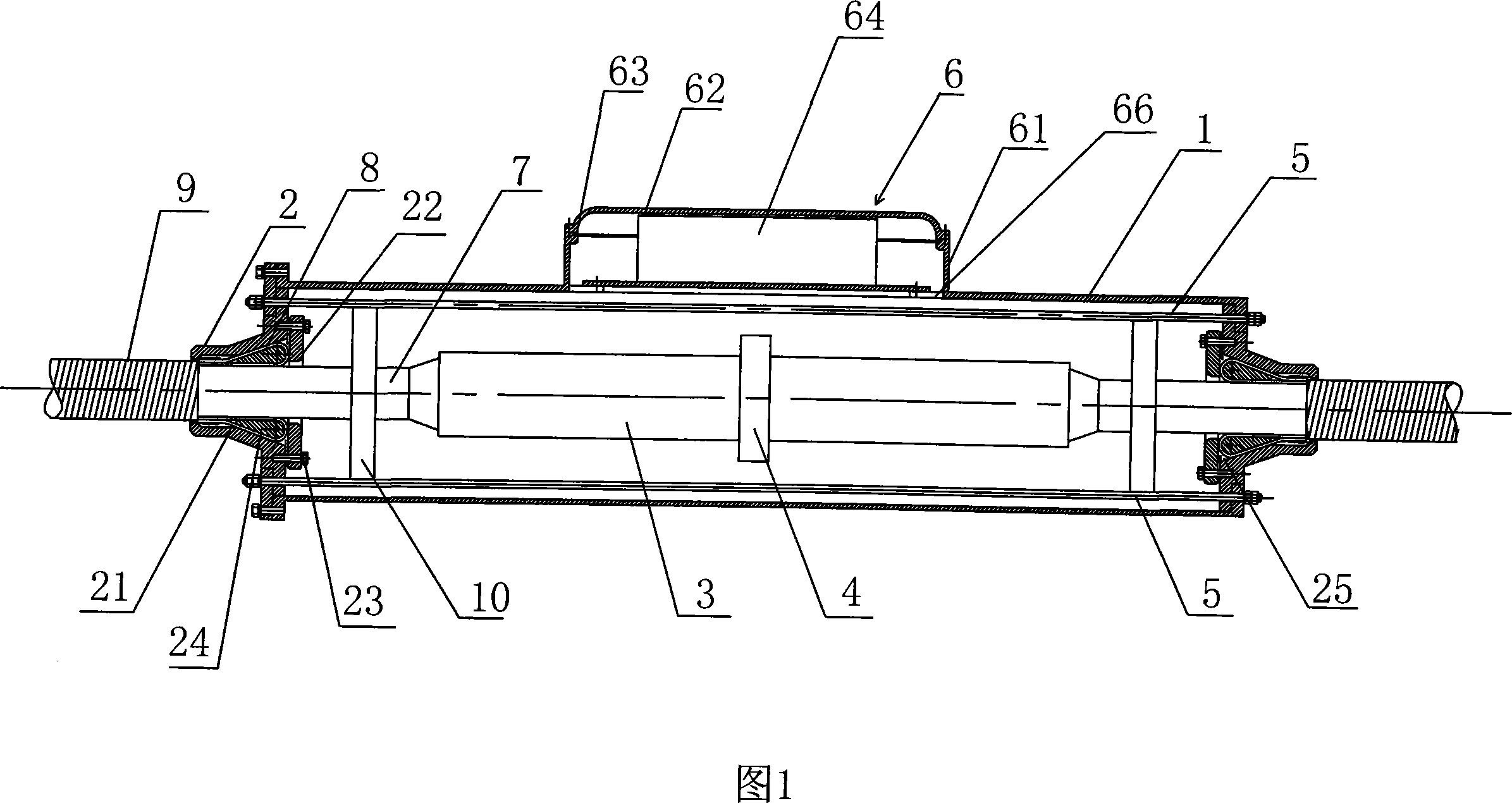

[0018] Embodiment 1: As shown in Figure 1, a repair joint of a photoelectric composite submarine cable, which includes a cylinder body 1 and cover plates 2 arranged at both ends of the cylinder body 1, the cylinder body 1 and the cover plate 2 cooperate to form an integral body, and the submarine cable 7. The through cover plate 2 is joined in the cylinder body 1. In this embodiment, the cylinder body 1 is made of hard organic material, which can be hard PVC or epoxy glass fiber reinforced plastic, and the surface is coated with a layer of epoxy paint for mechanical protection. effect. The cover plate 2 is provided with a sealing fixing part, and a set of conductive pull rods 5 is arranged between the sealing fixing part and the cylinder body 1. The sealing fixing part is electrically connected with the conductive pull rods 5. The setting of the conductive pull rods 5 not only ensures the armored The electrical connection between the steel wires effectively tightens the cylind...

Embodiment 2

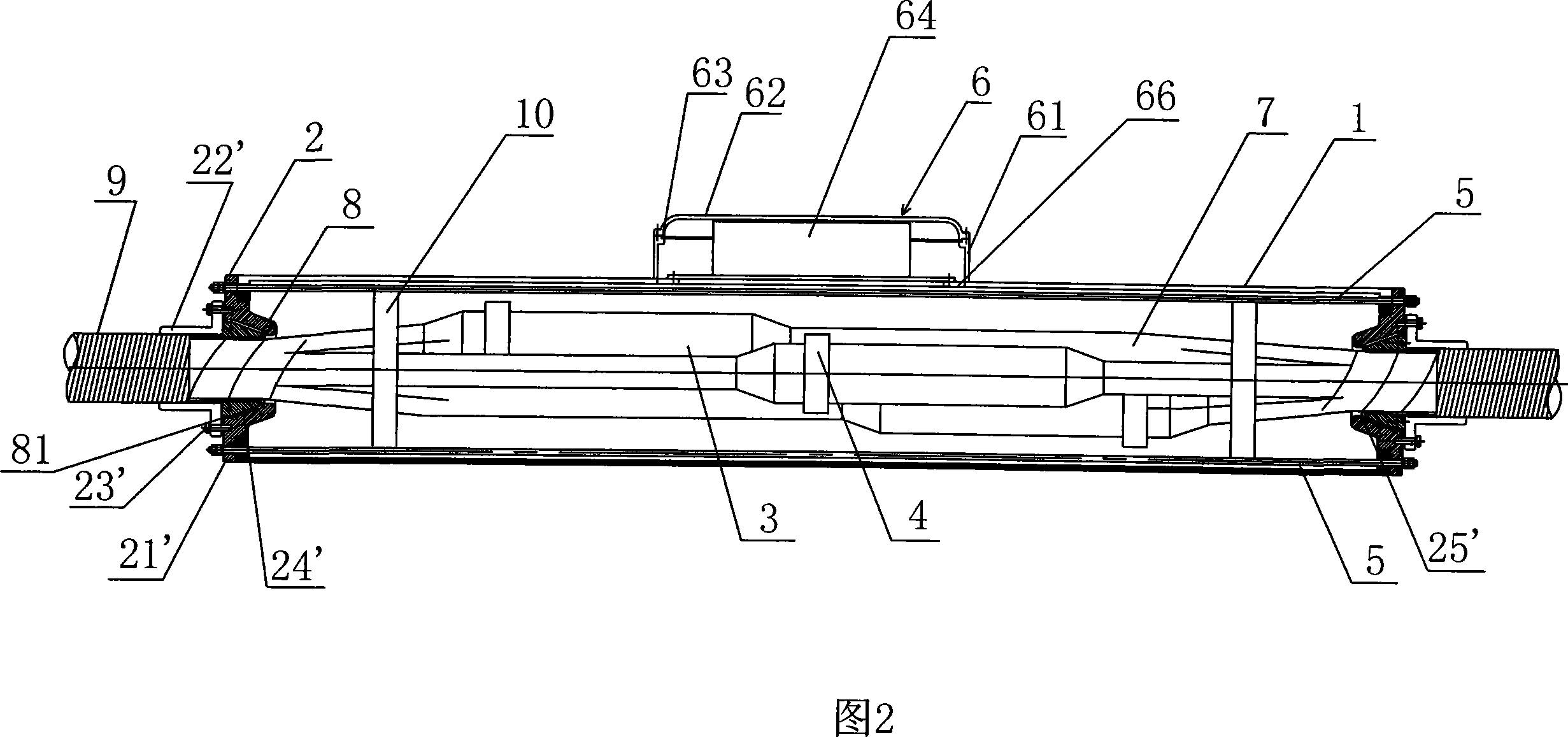

[0024] Embodiment 2: As shown in Figure 2, its structure is basically the same as that of Embodiment 1, the difference is that in this embodiment, the sealing fixture adopts another structure, which includes a tapered hole 25 located inside the cylinder body 1 'The conical base 21' and the L-shaped pressure plate 22' fixedly connected with the conical base 21' can be connected by screws 23'. A tapered sleeve 24' is arranged between the L-shaped pressure plate 22' and the tapered hole 25', and the armored steel wire 8 of the submarine cable 7 is wrapped outside the tapered sleeve 24', and the armored steel wire 8 and the tapered sleeve 24' are connected to the tapered hole 25. 'cooperate with each other, the free end 81 of the armored steel wire 8 and the L-shaped pressing plate 22' conflict with each other, one end of the L-shaped pressing plate 22' is connected with the sheath 9 of the submarine cable 7, the conical base 21', the L-shaped pressing plate 22' and the conical Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com