Method for preparing diglyceride

A technology of diglyceride and vegetable oil, applied in the direction of fermentation, etc., to achieve good industrial application prospect, good catalytic effect, and the effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

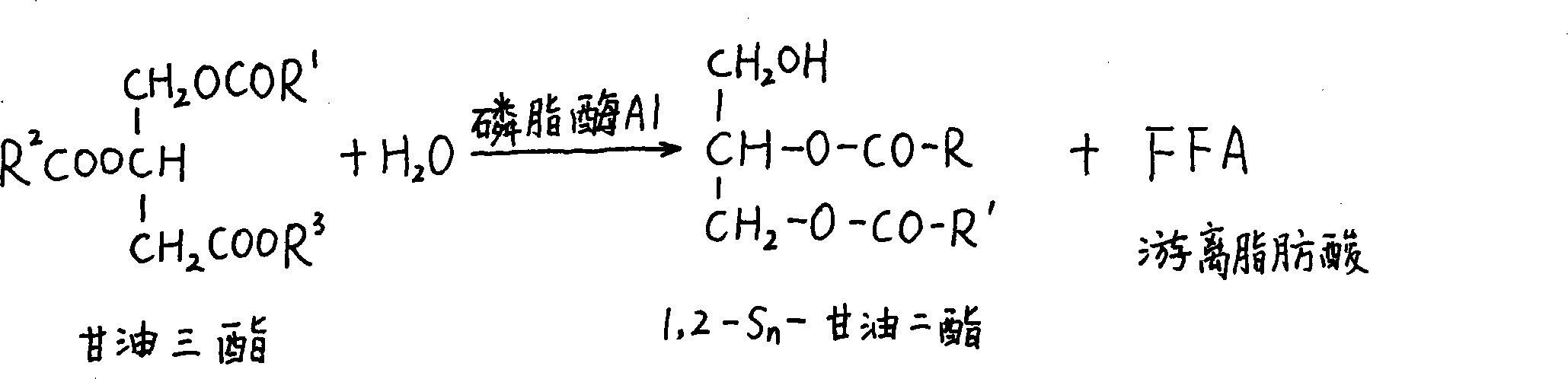

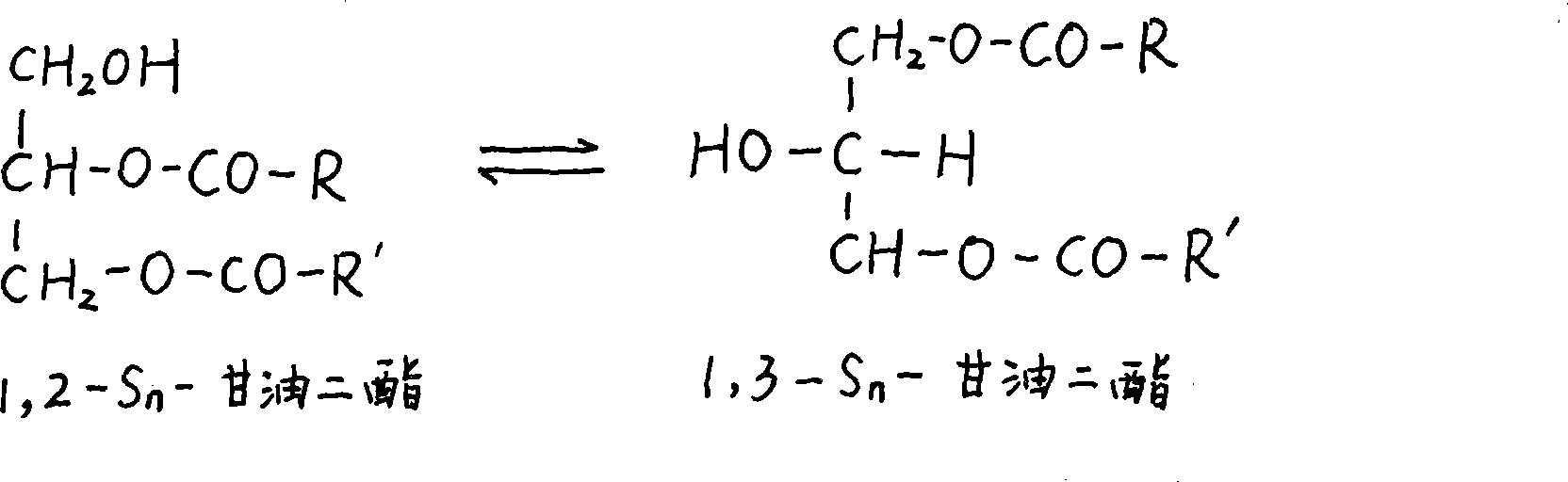

Problems solved by technology

Method used

Image

Examples

Embodiment 1

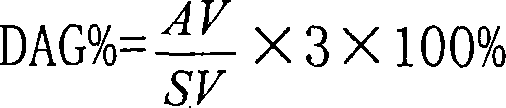

[0028] Weigh 100 g of refined soybean oil into a three-neck reactor, add 10 g of water and 0.05 g of phospholipase A1. The middle port of the three-neck reactor is connected to the stirrer, the left port is connected to the condenser, and the right port is closed with a ground plug. The reaction temperature was set at 50° C. and the stirring speed was 300 r / min for 4 hours. After the reaction, the reaction solution was poured into a separatory funnel and allowed to stand for 60 min to separate layers. The upper layer is an oil layer, and the lower layer is water and enzyme liquid. Drain the liquid in the lower layer, transfer the oil layer into a flask, and dry it by rotary evaporation for 30 minutes at an absolute pressure of 5000 Pa and a temperature of 90° C. to obtain crude diglyceride. The acid value of the crude diglyceride was determined to be 36.80 mgKOH / g.

[0029] Distill the crude diglycerides at 135°C, an absolute pressure of 30 Pa, and a stirring speed of 300 r...

Embodiment 2

[0031] Weigh 100 g of refined soybean oil into a three-neck reactor, add 36 g of water and 0.26 g of phospholipase A1. The middle port of the three-neck reactor is connected to the stirrer, the left port is connected to the condenser, and the right port is closed with a ground plug. The reaction temperature was set at 40° C. and the total stirring speed was 300 r / min to react for 8 hours. After the reaction, the reaction solution was poured into a separatory funnel and allowed to stand for 40 min to separate layers. The upper layer is an oil layer, and the lower layer is water and enzyme liquid. Drain the liquid in the lower layer, transfer the oil layer into a flask, and dry it by rotary evaporation for 40 minutes under an absolute pressure of 4000 Pa and a temperature of 80° C. to obtain crude diglyceride. The acid value of the crude diglyceride was determined to be 53.79 mgKOH / g.

[0032] Distill the crude diglyceride at 130°C, an absolute pressure of 20 Pa, and a stirri...

Embodiment 3

[0034] Weigh 100 g of refined peanut oil into a three-neck reactor, add 40 g of water and 0.18 g of phospholipase A1. The middle port of the three-neck reactor is connected to the stirrer, the left port is connected to the condenser, and the right port is closed with a ground plug. The reaction temperature was set at 30° C. and the total stirring speed was 300 r / min to react for 12 hours. After the reaction, the reaction solution was transferred to a centrifuge for centrifugation and layering. The upper layer is an oil layer, and the lower layer is water and enzyme liquid. Drain the liquid in the lower layer, transfer the oil layer into a flask, and dry it by rotary evaporation for 50 minutes at an absolute pressure of 6000 Pa and a temperature of 80° C. to obtain crude diglyceride. The acid value of the crude diglyceride was determined to be 53.36 mgKOH / g.

[0035] Distill the crude diglyceride at 140°C, absolute pressure 1Pa, and stirring speed 300r / min to remove the fatt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com