Alkali lignin modified sulfamate high-effective water reducer and preparation method thereof

A sulfamate and high-efficiency water-reducing agent technology, applied in the field of sulfamate high-efficiency water-reducing agent, can solve the problems of unfavorable concrete durability, poor concrete water retention, and many concrete bleeding channels, etc., and achieves slump The effect of small loss over time, easy availability of production raw materials and large slump

Inactive Publication Date: 2010-11-24

SOUTH CHINA UNIV OF TECH

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there are three problems in the production and application of sulfamate high-efficiency water reducers, which affect its production and popularization and application: First, the main raw materials, sodium p-sulfanyl sulfonate and phenol, are petroleum industry products, which are non-renewable Resources and raw materials are expensive, and production costs are high; second, the water retention of concrete is not good during the application process, and the phenomenon of segregation and bleeding is serious, and even the slurry is hardened and separated from water

Due to the large bleeding of the water reducing agent, there are many bleeding channels in the concrete, and the structure is prone to cracks, which has an adverse effect on the durability of the concrete; third, the main raw materials for production are phenol and formaldehyde, which are volatile toxic substances, and the products are often Contains relatively high free phenol or formaldehyde, which will cause great pollution to the environment and bring harm to operators. In the existing production process research, it has not been used as the main monitoring index

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

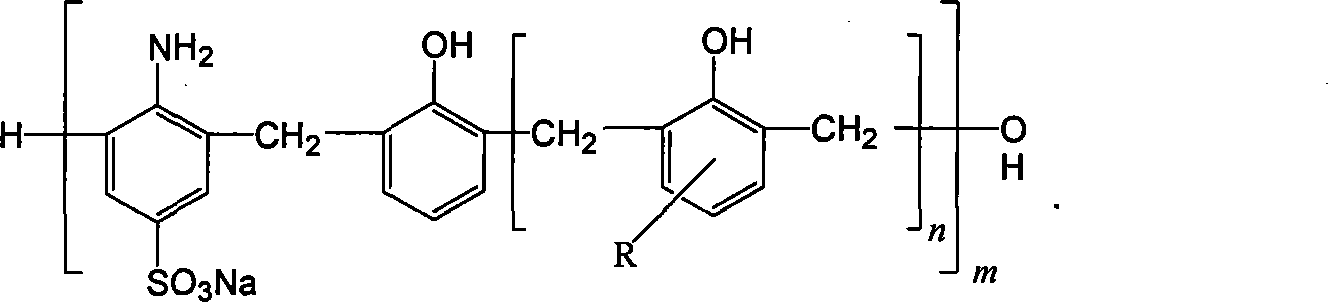

The invention discloses a preparation method of alkali lignin modified sulfamate highly effective water reducing agent, which includes the steps that: firstly, alkali lignin, phenol and water are evenly mixed, and an alkaline regulator is used to adjust the pH value of a reaction system to 8.0-10.0 and heat the temperature to 80-100 DEG C for half an hour to two hours; secondly, the pH value is adjusted to 9.0-11.0, and aminobenzene sulfonic acid sodium is added to react under the temperature of 60 to 80 degrees for half an hour to one hour; thirdly, the temperature is heated to 75-95 DEG C, and condensing agent is dropped. After that, the reaction continues for three to six hours and then the temperature is lowered. The obtained water reducing preparation, having low cost and small content of free formaldehyde and phenol, can improve the fluidity of concrete and compressive strength significantly. The preparation method is a simple technique without the discharge of three wastes in production.

Description

Alkali lignin modified sulfamate high-efficiency water reducer and preparation method thereof technical field The invention relates to a high-efficiency water reducer suitable for cement, concrete or mortar in construction engineering and a preparation method thereof, more specifically, a high-efficiency sulfamic acid salt prepared by modification using alkali lignin as raw material. Water reducing agent. Background technique With the continuous development of construction and engineering construction, the amount of concrete is increasing day by day. According to incomplete statistics, the world's annual output of cement exceeds 1.5 billion tons, which is equivalent to no less than 4.5 billion m3 of concrete, of which my country's concrete consumption is about 1.5 billion m3 . At present, the whole world starts from the speed, efficiency and cost of construction projects. The engineering structure and construction have continuously put forward new requirements for the perf...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B24/20C04B103/30

CPCC04B2103/30C04B40/0046

Inventor 邱学青庞煜霞欧阳新平杨东杰楼宏铭

Owner SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com