Apparatus for conforming a planar film on an optical lens, method for functionalizing an optical lens by means of said apparatus, the optical lens so-obtained

A technology for optical lenses and flat films, applied to a device for forming flat films on optical lenses, which can solve the problems of repeated reproducibility, limited use conditions, and difficulties in optical lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0154] Example 1: Cold "UV embossing (molding)" in ophthalmic lenses using a commercial film Anti-reflection microstructures are implemented on the convex surface of the sheet,-enabled devices containing equipment capable of controlling the A vacuum device that translates the piston.

[0155] A commercial acrylic coating (SHC 3100-LTI) with a thickness of 3 microns (μm) was deposited by spin coating onto the convex surface of the lens having a radius of curvature of 120 mm and a diameter of 65 mm.

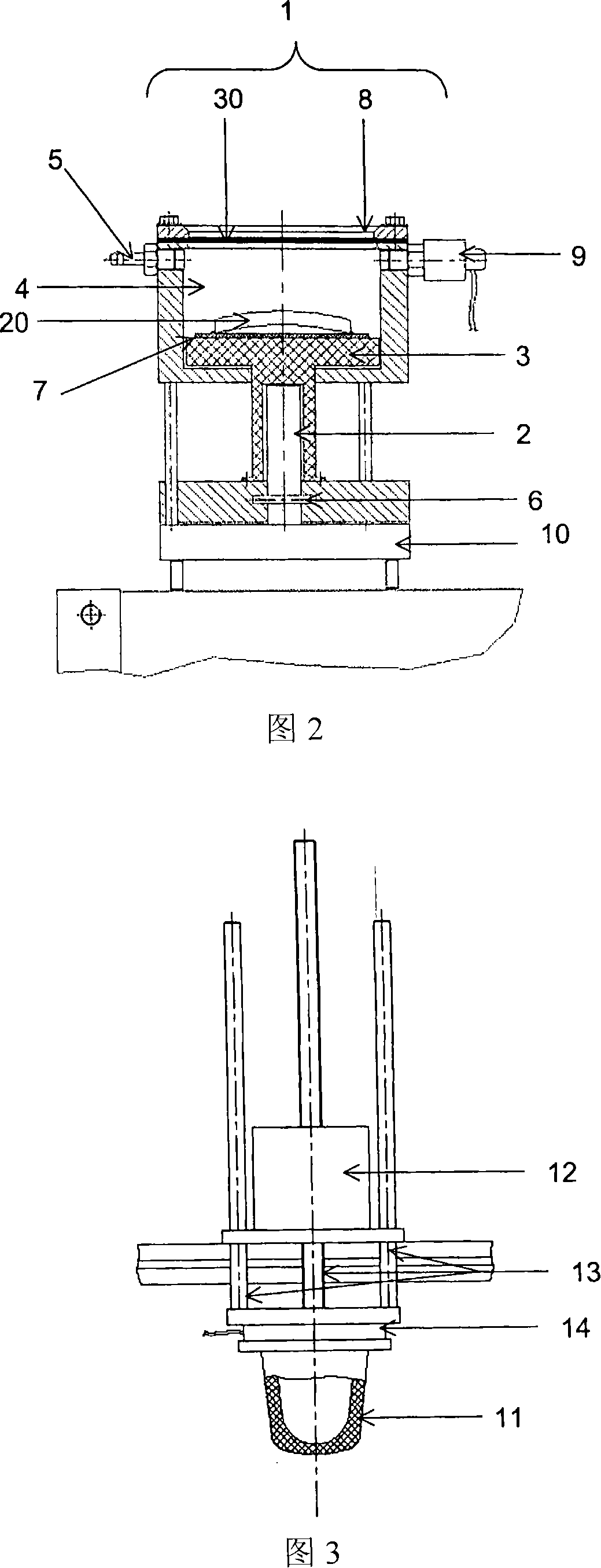

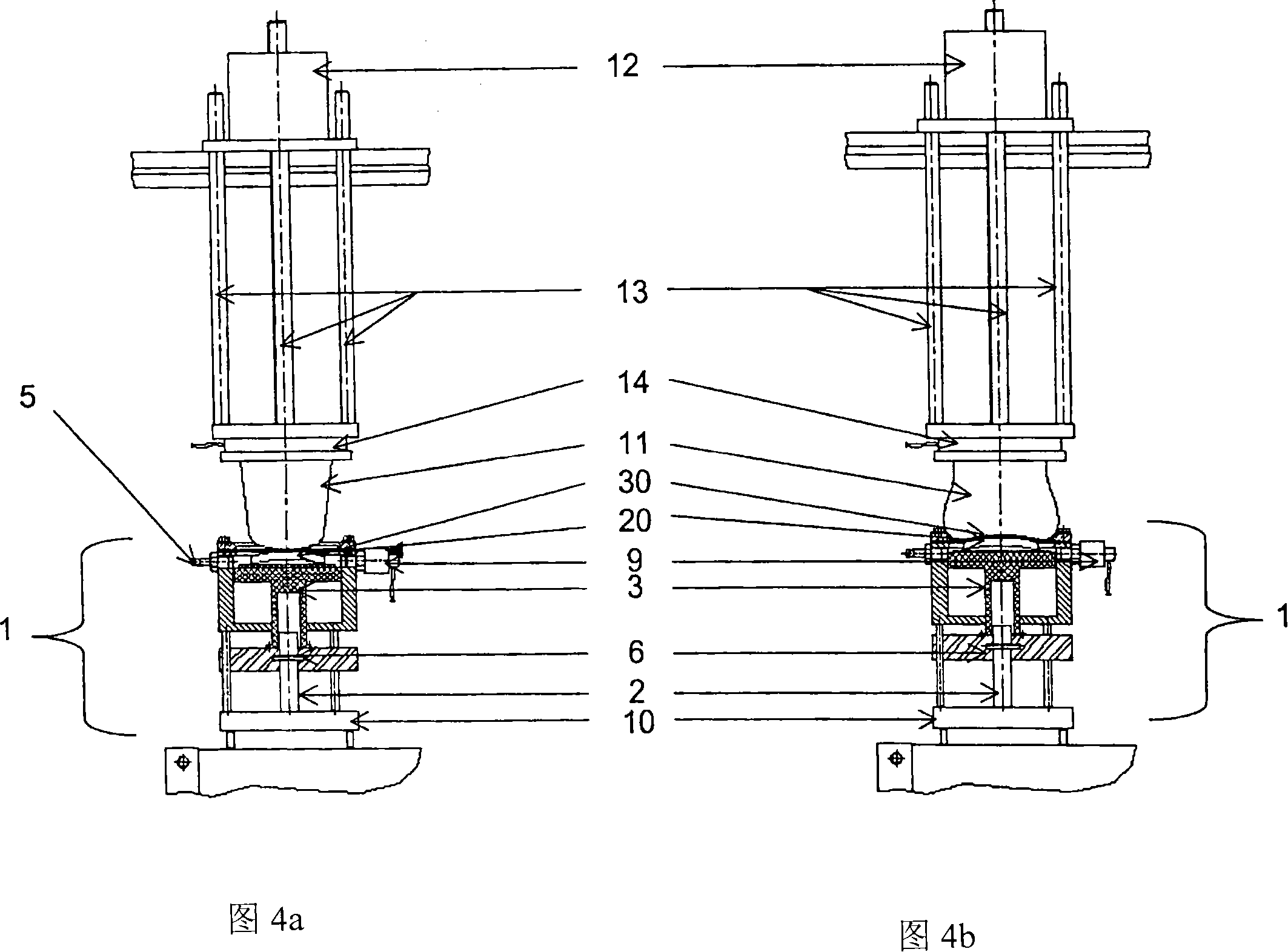

[0156] The optical lens 20 is placed convex side up on the lens carrier 7 in the module 1, the module being sealed by a planar flexible membrane 30 supported in the membrane carrier 8, said flexible membrane being The PET (polyethylene terephthalate) film is also functionalized on its inner side by using a microstructured coating. The membrane was realized by embossing, the total thickness of the membrane (PET+microstructured coating (functionalization)) was 100 micrometers (μ...

Embodiment 2

[0163] Example 2: Using PDMS Microstructured Replicas on the Concave Surface of an Ophthalmic Lens Cold "UV imprinting (molding)" achieves anti-reflective microstructures, -enabling devices containing packaged A vacuum device is provided to control the translation of the piston.

[0164] A commercial acrylic coating (SHC 3100-LTI) having a thickness of 3 microns (μm) was deposited by spin coating onto the concave surface of a lens having a radius of curvature of 81 mm and a diameter of 65 mm.

[0165] The optical lens is placed concave side up on the lens carrier in the module, and the module is sealed by a planar flexible membrane supported in the lens carrier, the flexible membrane is on its inner side PDMS membrane microstructured on the face, UV (Sygard 184-Dow Corning) and having a thickness of 2 mm. The membrane, having a Shore hardness of 50 Shore A and a tensile modulus of rupture of 140%, was obtained by molding a replica from a microstructured master made of ni...

Embodiment 3

[0172] Example 3: Using a thermistor to bond a diaphragm to the convex surface of an optical lens, - the device used The device comprises a vacuum device equipped with the ability to control the translation of the piston.

[0173] Said lens, having a radius of curvature (convex) of 120 mm and a diameter of 65 mm, is placed convexly upwards (upper end 1 a of said module 1 ) on a lens carrier 7 in a module 1 supported by support means 9 The flat flexible membrane 30 in the membrane carrier 8 is sealed by a commercial membrane made of PET with a thickness of 75 microns (μm) (ARclear(R) DEV-8796-Adhesives Research , Inc.) and was coated with a layer of adhesive (Pressure Sensitive Adhesive - PSA) with a thickness of 25 micrometers (μm).

[0174] Arranged in said module 1 is a movable heating device 200 which, by means of hot air convection, makes it possible to raise the temperature of the membrane sealing said module, which in this way is heated to 160 °C, once the desired t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com