System for generating plasma body

A plasma and coil technology, applied in the field of semiconductor manufacturing, can solve the problems affecting the flattening effect of the wafer, weak plasma energy, etc., and achieve the effects of consistent etching and deposition rates, increased electromagnetic field strength, and reduced energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

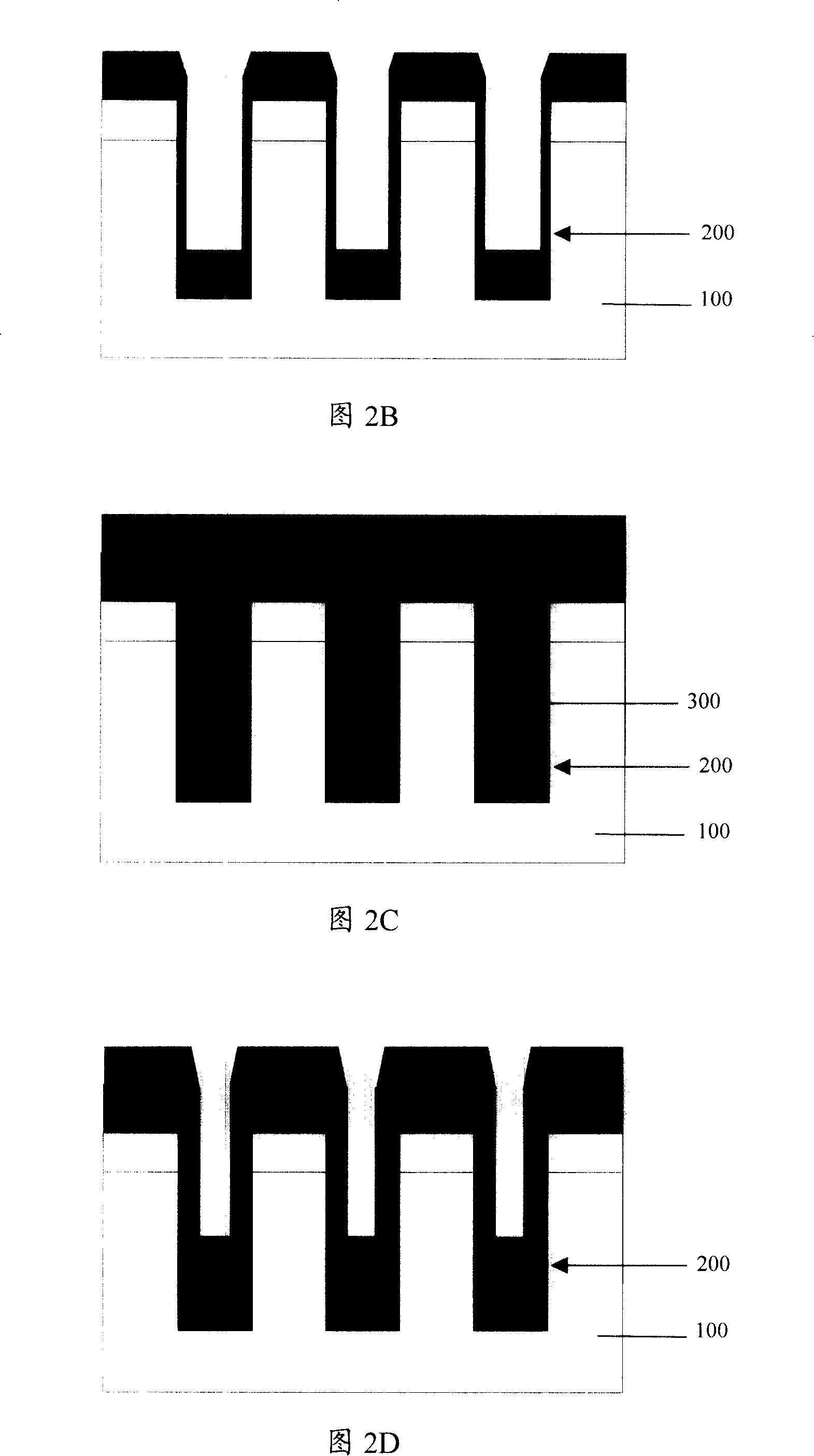

[0035] The invention relates to the technical field of semiconductor integrated circuit manufacturing, in particular to a method for forming a shallow trench isolation structure in a semiconductor device and the shallow trench isolation structure. It should be noted here that this specification provides different embodiments to illustrate the various features of the present invention, but these embodiments are only for convenience of description by using specific compositions and structures, and do not limit the present invention.

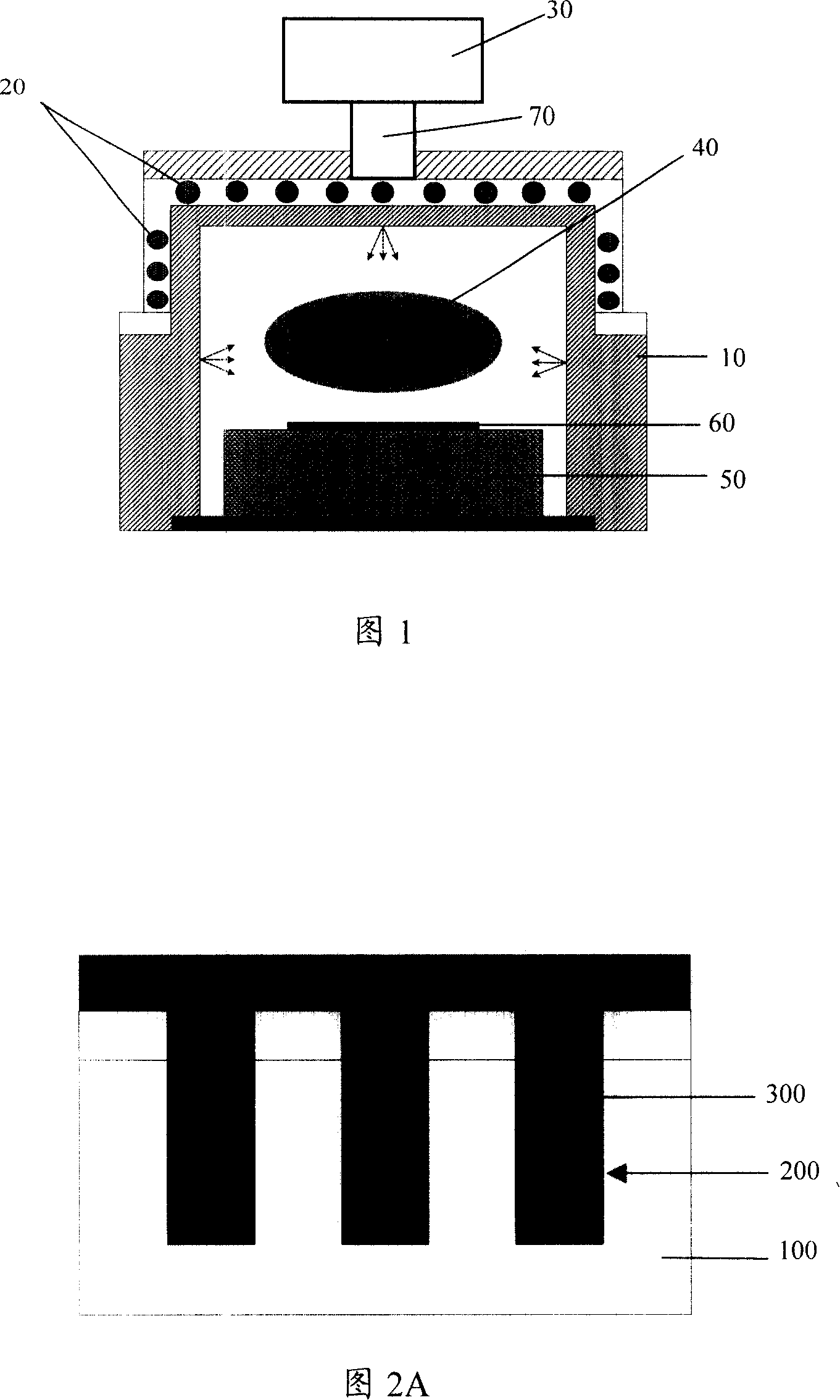

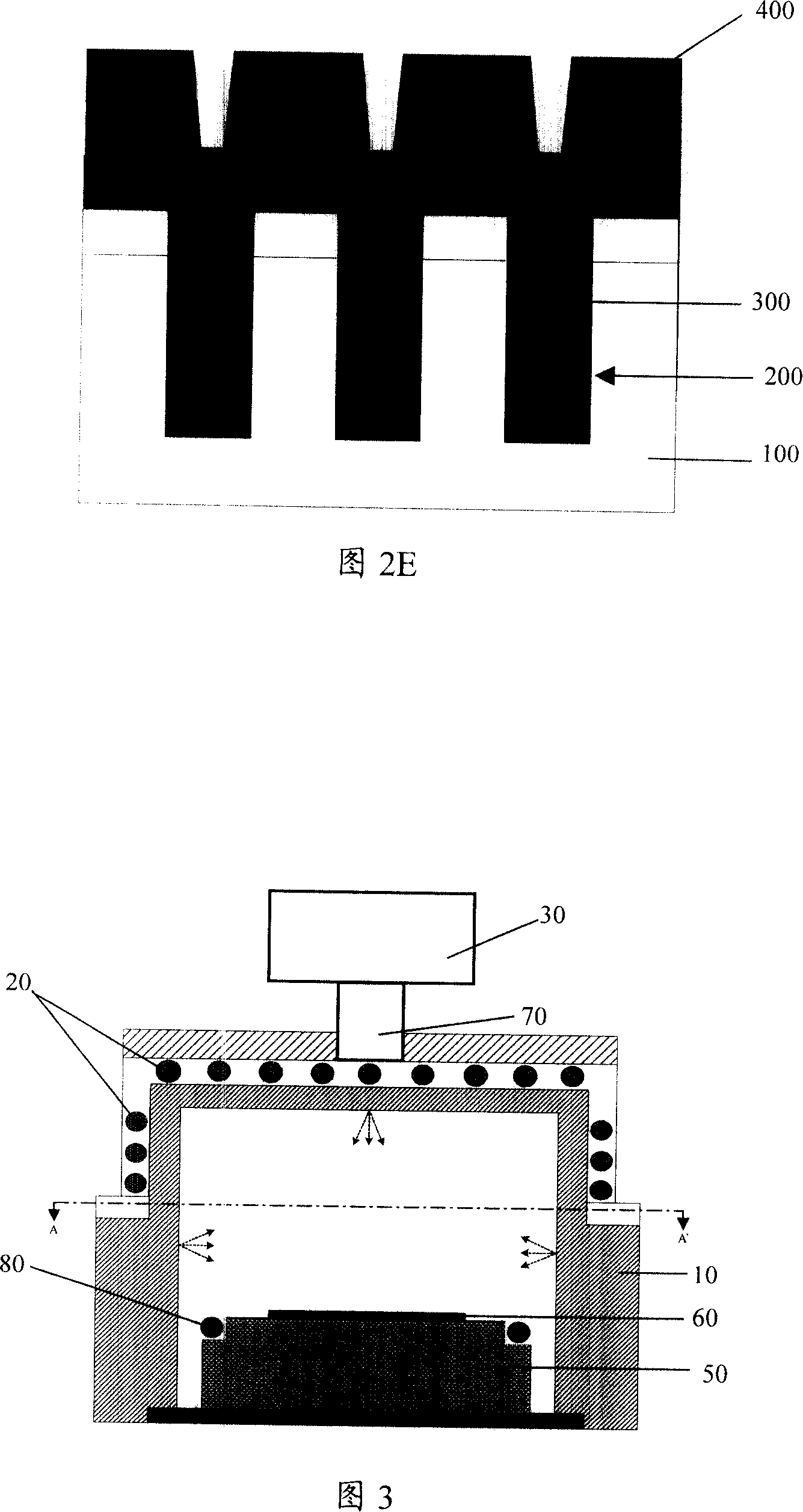

[0036] FIG. 3 is a simplified schematic diagram of a system structure for generating plasma according to an embodiment of the present invention. The schematic diagram is just an example, which should not li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drive current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com