Fan system, electric motor, and claw-pole motor

A fan system, salient-pole technology, applied in the field of fan systems, can solve the problems of low vibration and noise, and achieve the effect of low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

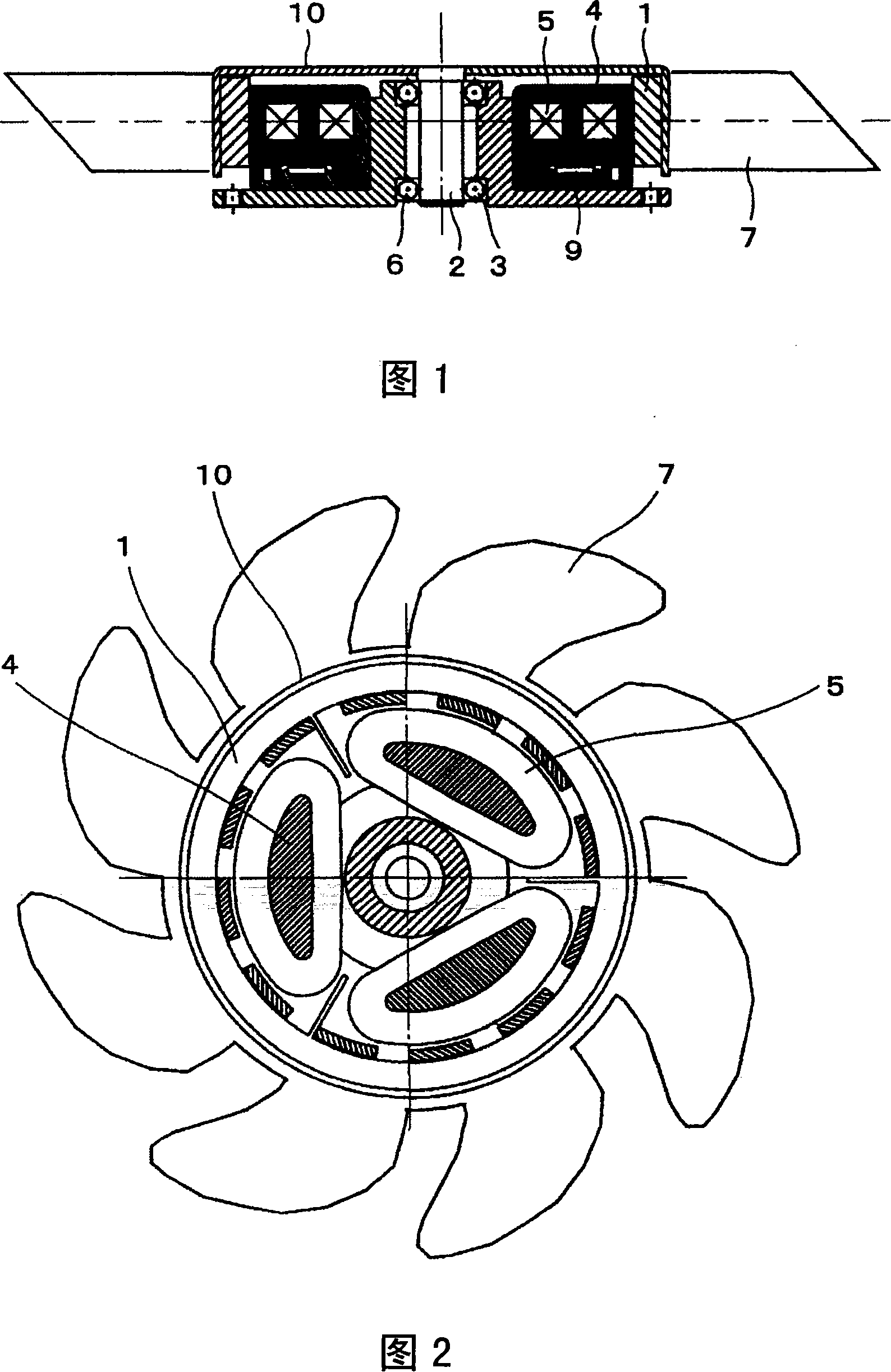

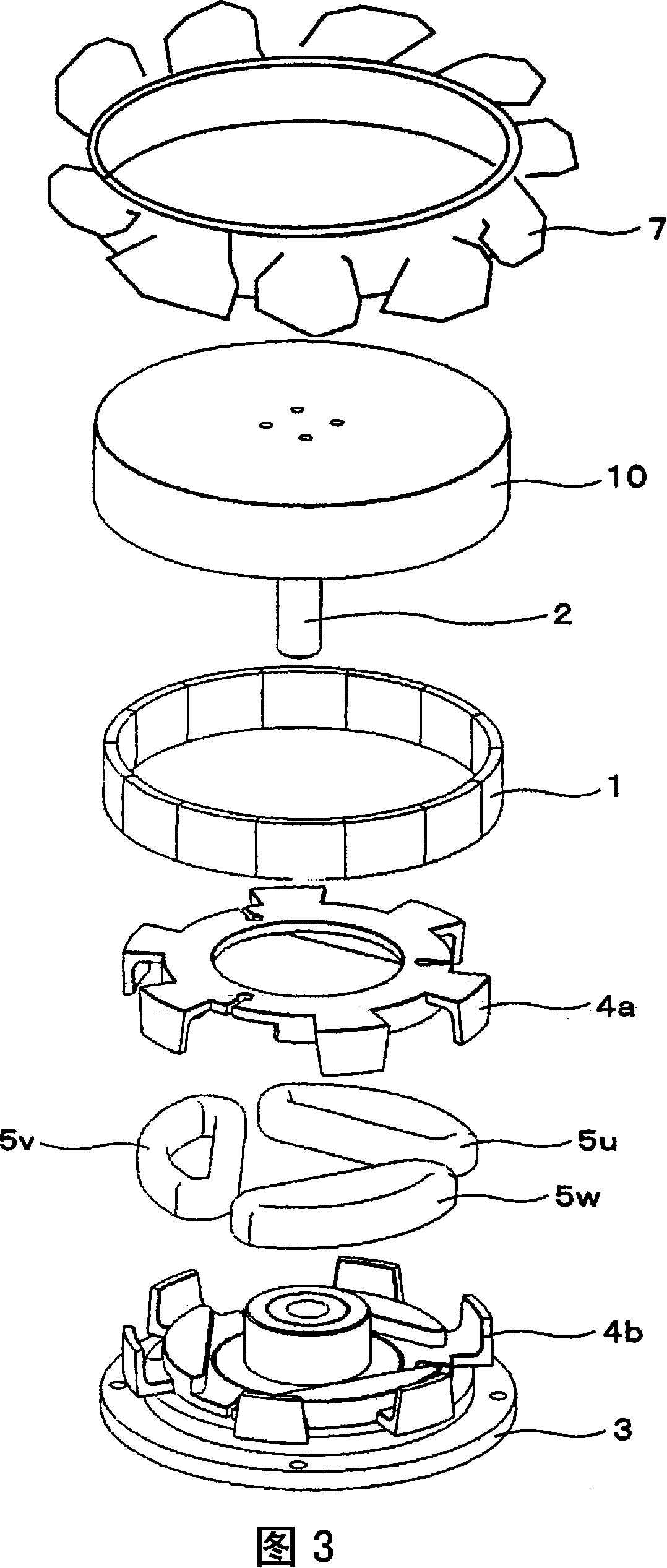

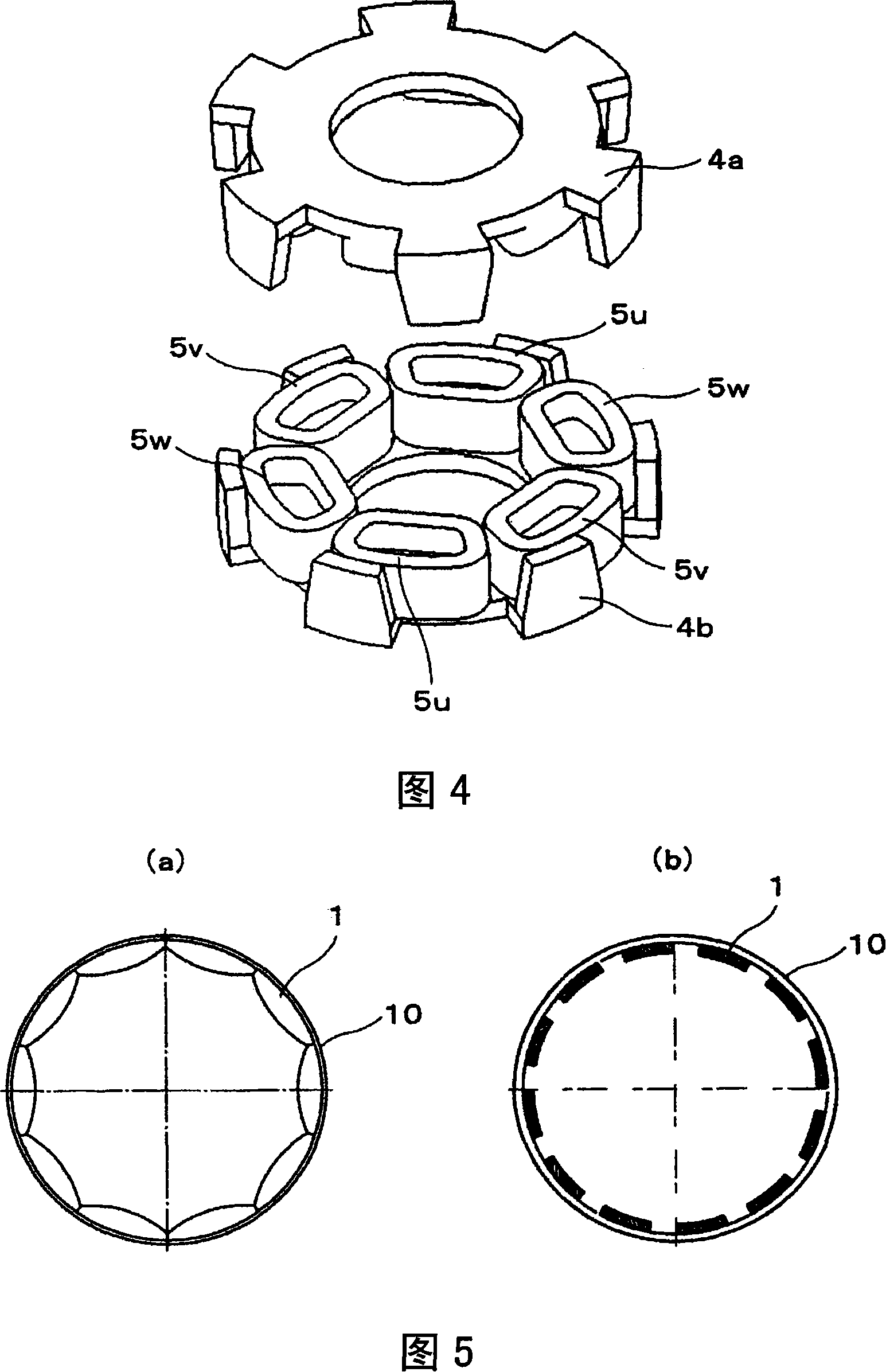

[0039] Fig. 1 shows the structure of the thin fan system of the present invention by means of a sectional view. The driving source is configured by arranging an outwardly rotating salient pole motor having a plurality of phase windings in one plane, and disposing blades on the outside of the yoke of the rotor. The salient pole motor has a structure in which a stator winding 5 is built inside a stator core 4, and the end of the winding is not exposed in the axial direction of the stator core. On the stator composed of the stator core 4 and the stator winding 5 , a control board 9 is mounted so as to ensure insulation by an insulating plate or the like, thereby constituting a stator assembly. The stator assembly is configured with the coaxiality and right angle of the bracket 3 holding the bearing, and the rotor yoke 10 combined with the shaft 2 held by the bearing. The magnet and the stator assembly arranged on the rotor yoke 10 pass through the gap It is rotatable on its oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com