Direct driving reluctance motor

A reluctance motor, direct technology, applied in electrical components, electromechanical devices, synchronous motors with static armatures and rotating magnets, etc., can solve the problem of large excitation power, increase the cost of the drive system, limit the performance volume ratio of the motor, etc. problem, to achieve the effect of reducing excitation consumption, volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

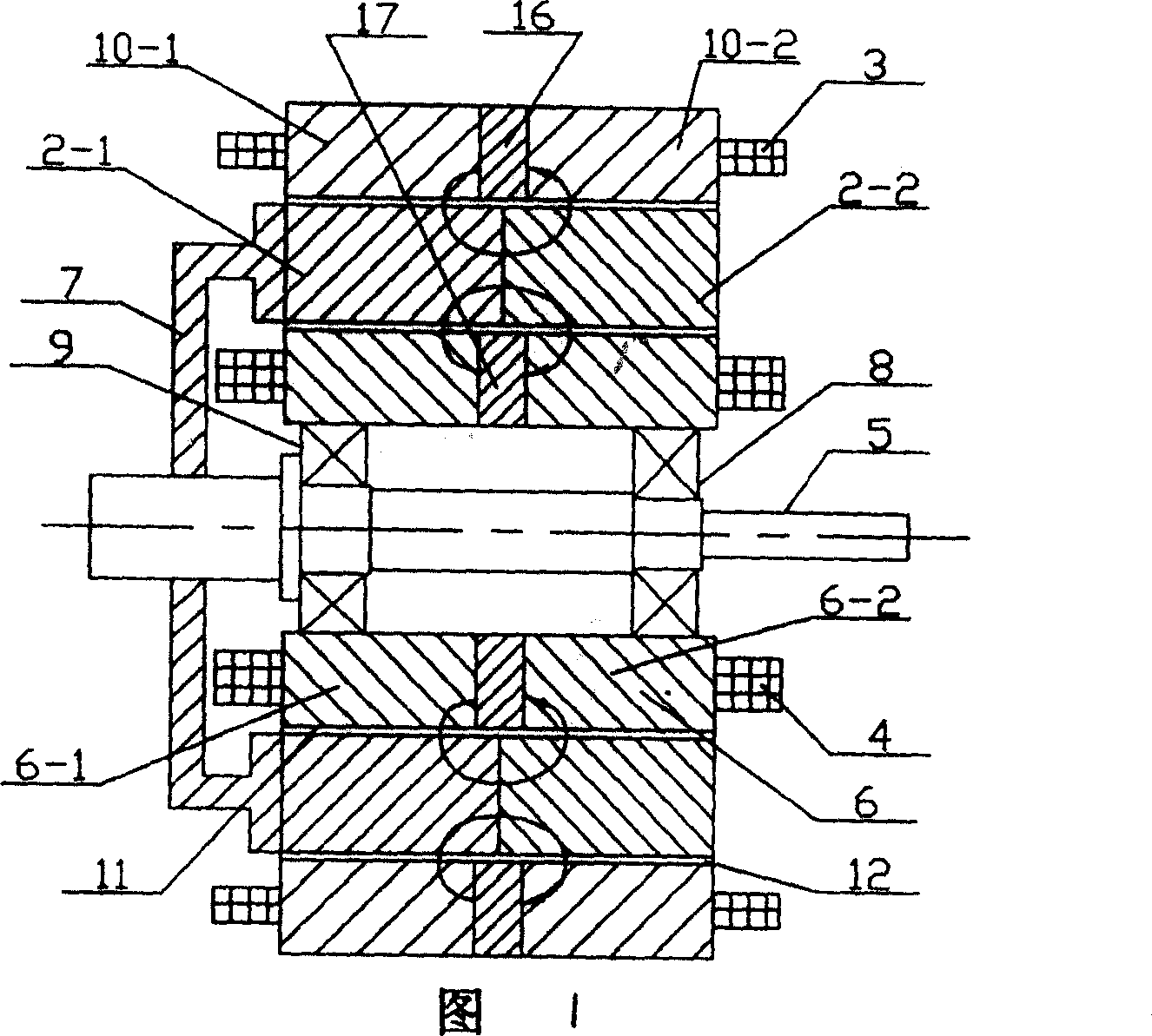

[0007] Embodiment: A direct-drive reluctance motor. The outer circle of the rotor core made of silicon steel sheets and the inner circle of the outer stator core made of silicon steel sheets form an outer air gap, and the inner circle of the rotor core and the outer circle of the inner stator core form an inner air gap. Air gap, tooth slots are opened on the inner circle of the outer stator core and the outer circle of the inner stator core, the outer stator and the inner stator excitation winding are respectively arranged on the inner circle of the outer stator core and the outer circle of the inner stator core, and the rotor cage is made of non-magnetic material Fixed on the shaft to support the rotor core, the shaft is embedded in the inner hole of the inner stator core through the bearing, and the circular permanent magnet 16 filled with a magnetic field in the axial direction is arranged in the middle of the length direction of the outer stator core 10 and puts the outer st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com