Regeneration method for printer cartridge

A technology for printers and ink cartridges, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of air leakage, damage, and ink leakage of ink cartridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

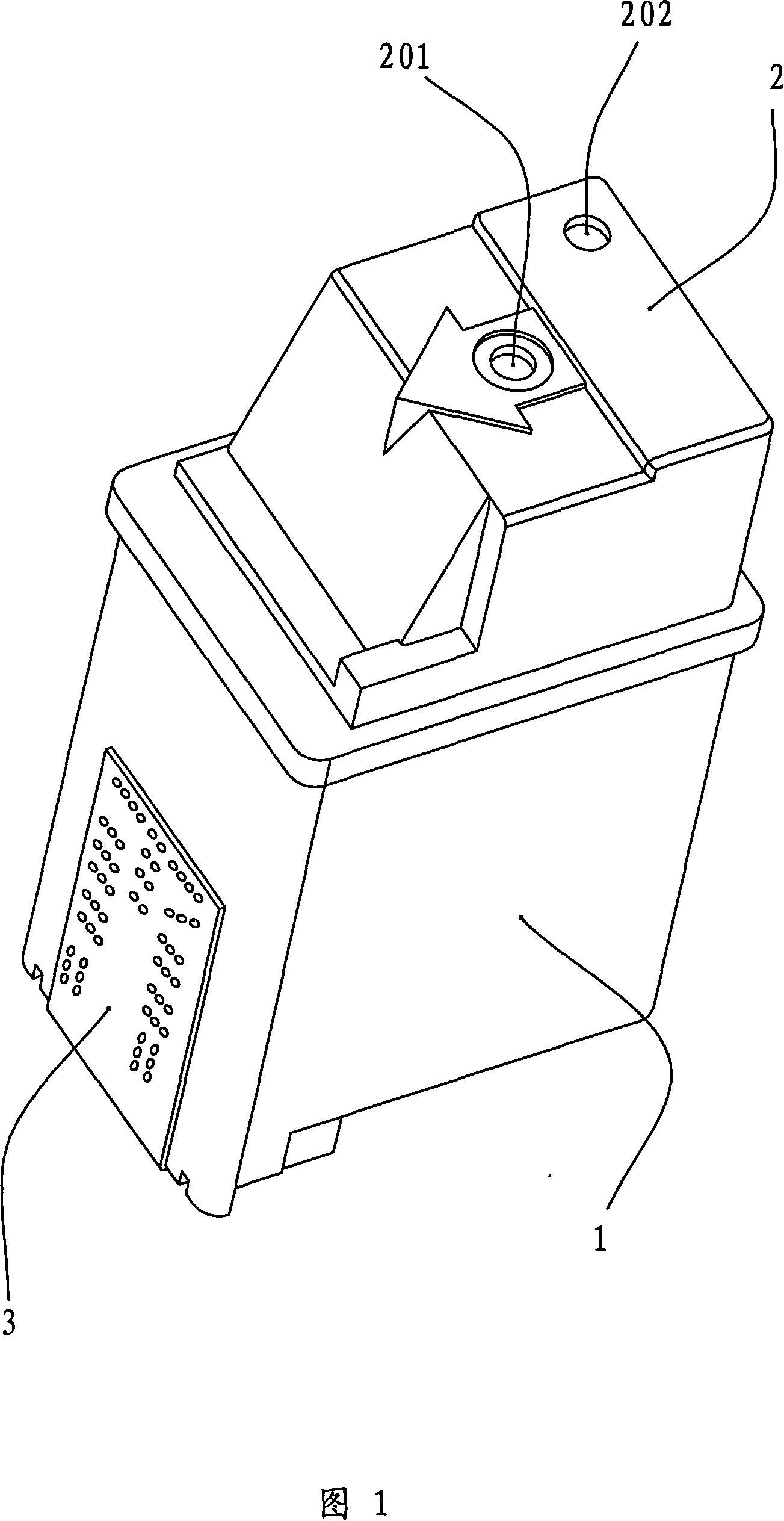

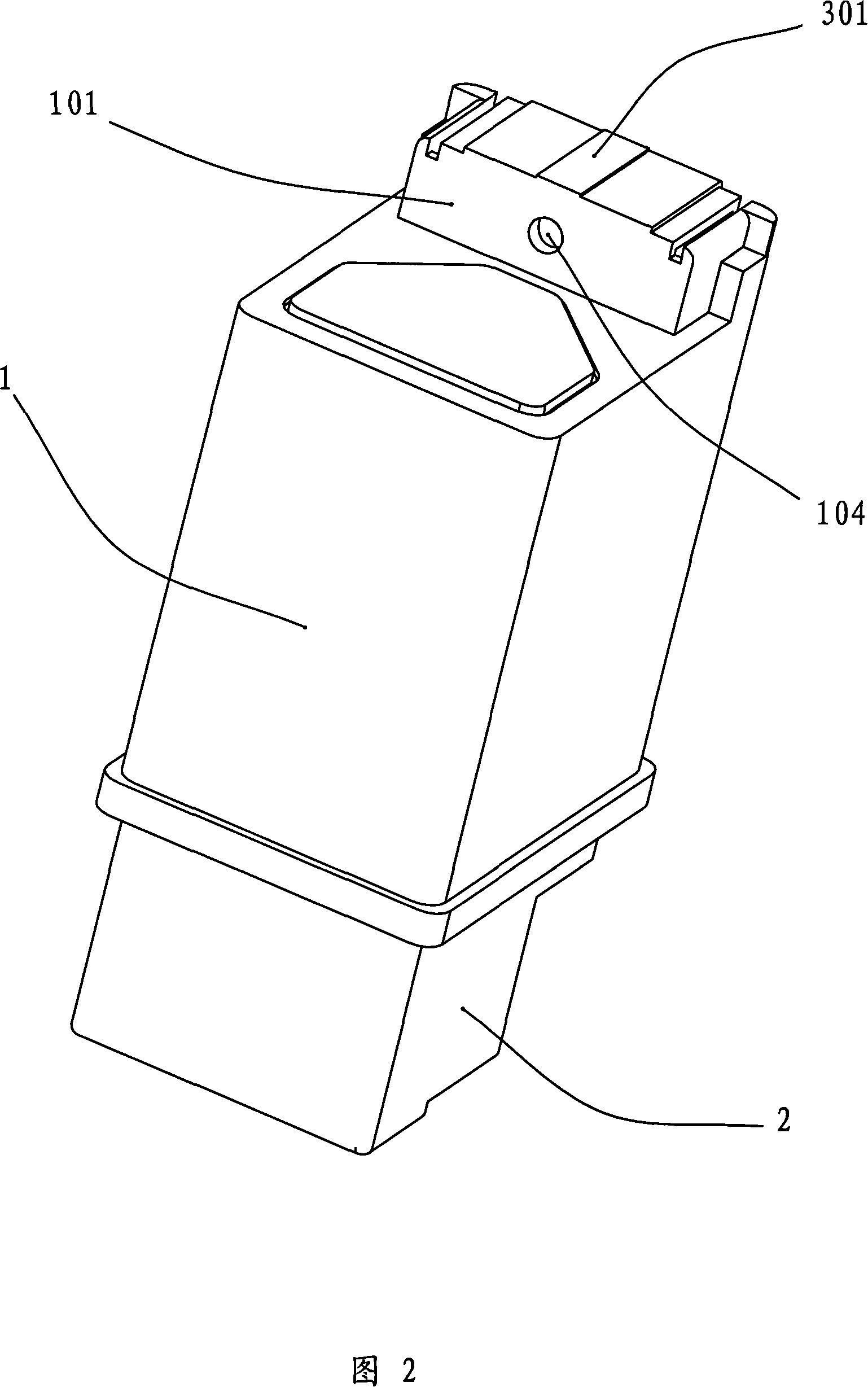

[0033]Referring to Figures 1, 2, and 3, it is a conventional ink jet printer ink cartridge. The shape of the ink cartridge is generally a rectangular parallelepiped, which is formed by connecting and surrounding a plurality of side walls. Its structure includes a box body 1 , a box cover 2 and a print head substrate 3 . After the box body 1 and the box cover 2 are fastened together, a hollow inner cavity of the ink cartridge for storing ink (not shown in the figure) is formed. A boss 101 extends from the bottom end of the box body 1 relative to the box cover 2 . An ink supply port communicated with the ink storage chamber of the ink cartridge is opened on the boss 101 , and the ink supply port is closed by the corresponding print head 301 on the print head substrate 3 . Inside the boss 101 is an ink channel (not shown) that communicates with the ink storage chamber of the ink cartridge and the print head 301 , and constitutes an ink supply passage from the ink storage chambe...

Embodiment 2

[0045] For the ink cartridges with the structures shown in Figures 1, 2, and 3, after the ink in the ink storage chamber is exhausted due to normal use, for example, the ink is normally supplied to the inkjet printer, a recycling method including the following sequential process steps is used to recover the ink regeneration:

[0046] First, an adhesive is applied on the periphery of the air hole 201 of the ink cartridge box cover and the periphery of the adhesive film 4 covering the air hole 102 at the bottom of the box body respectively. UV light irradiates the adhesive to cure it. The wavelength of ultraviolet light is 0.04-0.39 microns, and the irradiation time is 4-8 seconds.

[0047] Next, a first through hole 202 connecting the ink storage chamber and the external atmosphere is formed on the ink cartridge cover 2 by drilling or punching, and a second through hole 202 is formed on the ink cartridge case body wall between the filter screen and the print head 301 Through ...

Embodiment 3

[0054] For the ink cartridges with the structures shown in Figures 1, 2, and 3, after the ink in the ink storage chamber is exhausted due to normal use, for example, the ink is normally supplied to the inkjet printer, a recycling method including the following sequential process steps is used to recover the ink regeneration:

[0055] First, an adhesive is applied around the air hole 201 of the cartridge cover. UV light irradiates the adhesive to cure it. The wavelength of ultraviolet light is 0.04-0.39 microns, and the irradiation time is 4-8 seconds.

[0056] Then, the adhesive film 4 covering the air hole 102 at the bottom of the box is removed and replaced with a new adhesive film. The new adhesive film is fixed on the periphery of the air hole 102 at the bottom of the box body by melting the periphery of the air hole 102 at the bottom of the box body.

[0057] Afterwards, an adhesive with the same composition as that applied to the periphery of the air hole 201 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com