Temperature sensitive chitosan hydrogel

A chitosan and gel technology, applied in the field of chitosan hydrogel and its preparation, can solve the problems of increasing the patient's economic burden, pain, non-biodegradation, accelerated degradation, etc., and avoid organic chemical reagents and other harmful substances. , The effect of high temperature responsiveness and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

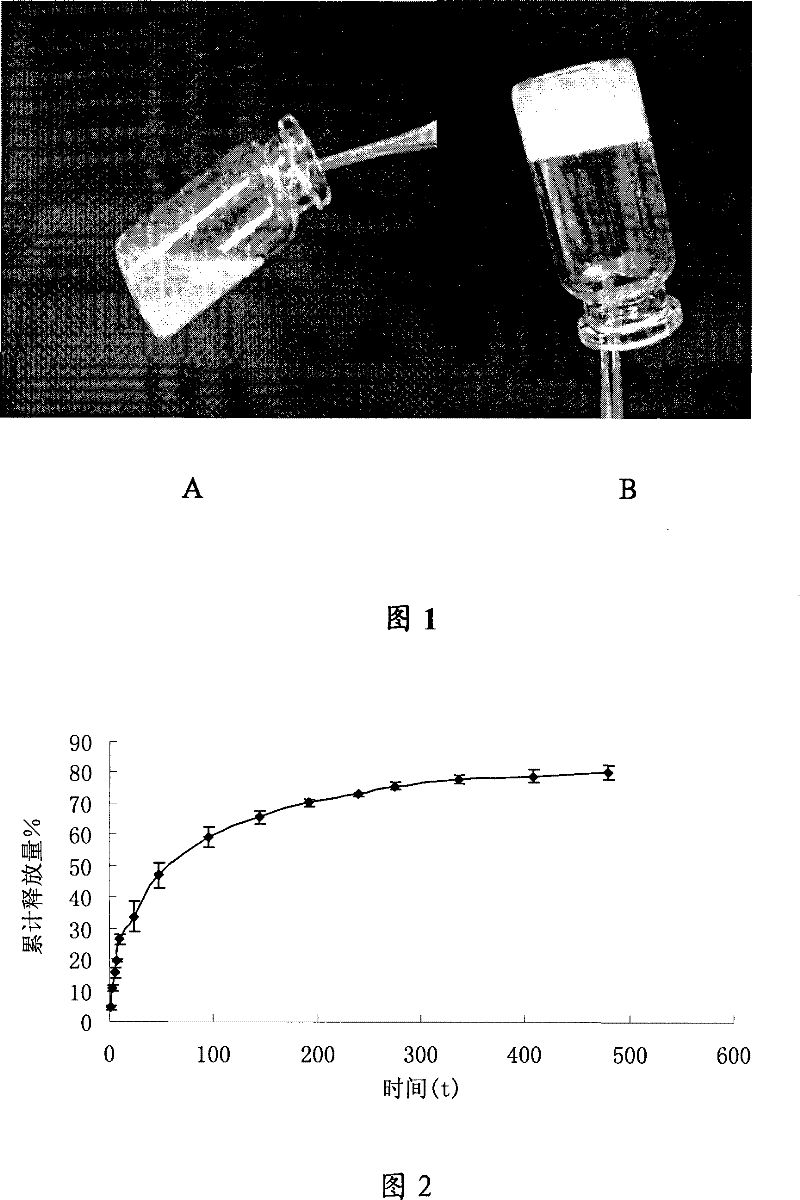

[0031] Dissolve 0.1 g of chitosan in 5 mL of 1mol / L glacial acetic acid solution and dissolve completely. 1.5 g glycerol was added. Add 3.4 mL of 15% (w / v) borax solution dropwise under stirring condition, and stir well to make it evenly mixed. The resulting solution had a pH of 7.0. The mixed solution was heated to 37°C and kept at a constant temperature for 20 minutes to fully gel the system. The system is stable at 4°C. Chitosan, glycerin, borax mixed solution, and photos of chitosan hydrogel gelled at 37°C figure 1 shown.

Embodiment 2

[0033] Dissolve 0.1 g of chitosan in 5 mL of 1mol / L glacial acetic acid solution and dissolve completely. 0.7 g of mannitol was dissolved in 3.7 mL of distilled water. Under the condition of stirring, 2.9 mL of 10% (w / v) borax solution was added dropwise, fully stirred to make it evenly mixed, and the pH value of the obtained solution was 7.0. The mixed solution was heated to 37°C and kept at a constant temperature for 20 minutes to fully gel the system. The system is stable at 4°C.

Embodiment 3

[0035] Dissolve 0.1 g of chitosan in 5 mL of 1mol / L glacial acetic acid solution and dissolve completely. 1.5 g glycerol was added. Add 3.4 mL of 15% (w / v) borax solution dropwise under stirring condition, and stir well to make it evenly mixed. Add 20% bovine serum albumin (BSA, model drug) to the mixed solution to dissolve, and mix evenly. The mixed solution containing bovine serum albumin was heated to 37°C and kept at a constant temperature for 20 minutes to fully gel the system. The system is stable at 4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com