Large cone rubber guard rail and its making method

A technology of rubber fenders and manufacturing methods, applied in chemical instruments and methods, lamination devices, ships, etc., can solve the problems that waste tires do not have bending resistance and shear resistance, and wood piles are easy to waste wood, etc., and achieve ideal protection. effect, saving natural wood and manpower, improving the ability to resist bending and shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

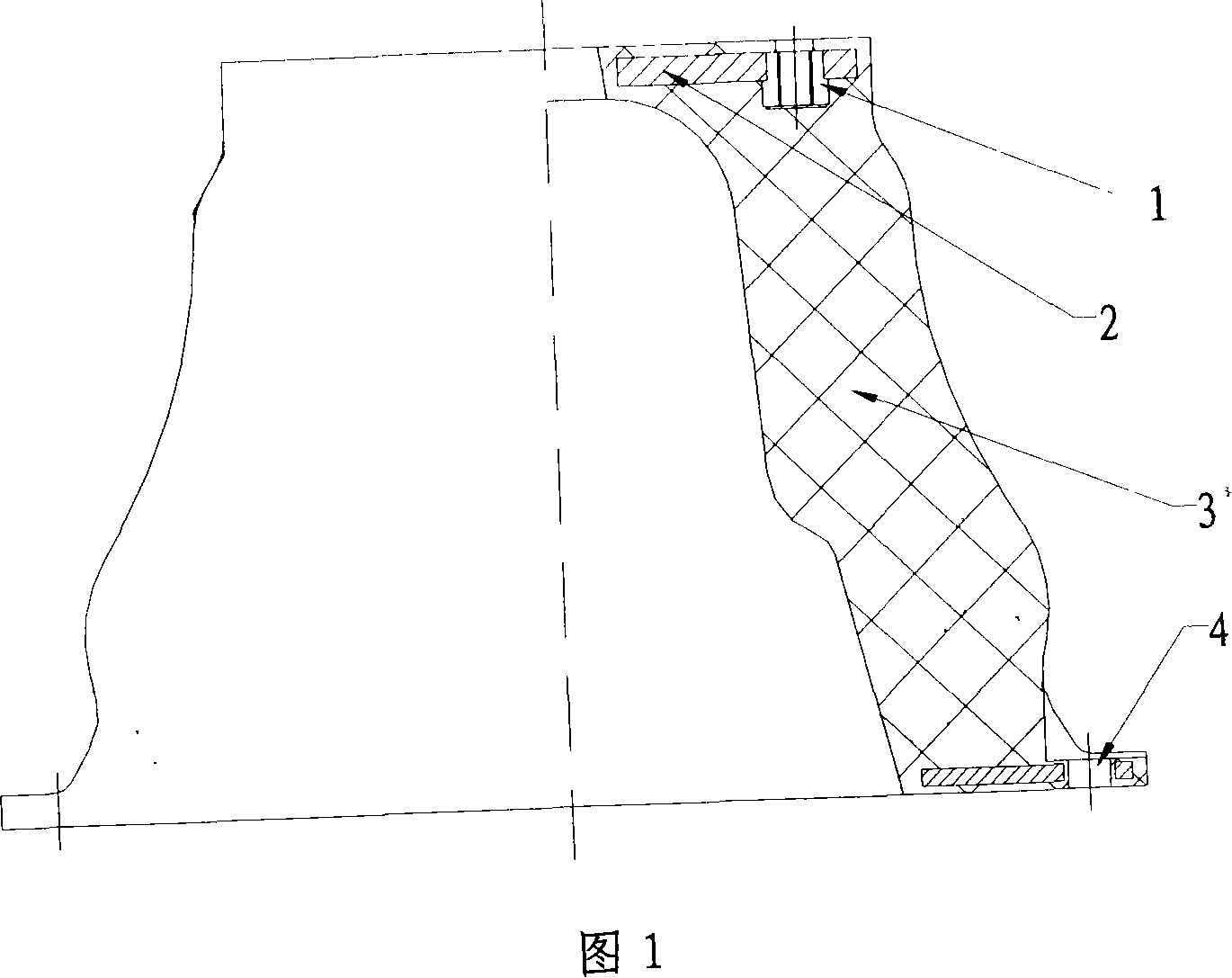

[0006] Embodiment 1: Referring to Figure 1, a large conical rubber fender is characterized in that the hollow conical rubber body 3 is provided with embedded nuts 1 and embedded frame steel plates 2 on the front plane, and bolt holes 4 are provided on the rear plane .

[0007] A method for manufacturing a large conical rubber fender, characterized in that: A, the steel plate is blanked, sand blasted to remove rust, brushed with metal adhesive, and the steel plate is covered with glue; B, according to: raw rubber 52%, S And NS2%, carbon black 40%, aromatic oil 4%, 4010NA2% as the main components, and then add CTP according to 0.5% of the main components, the raw rubber is masticated, mixed, and then processed with the skeleton steel plate prepared in step A. Co-extrusion, vulcanization, unmolding, repair and warehousing of twin extruders.

Embodiment 2

[0008] Embodiment 2: Referring to Figure 1, a large conical rubber fender is characterized in that the hollow conical rubber body 3 is provided with embedded nuts 1 and embedded frame steel plates 2 on the front plane, and bolt holes 4 are provided on the rear plane .

[0009] A method for manufacturing a large conical rubber fender, characterized in that: A, the steel plate is blanked, sand blasted to remove rust, brushed with metal adhesive, and the steel plate is coated with glue; B, according to: raw rubber 56%, S And NS 2.5%, carbon black 36.5%, aromatic oil 3%, 4010NA 2% as the main ingredients, and then according to the main ingredients of 0.6% CTP, add raw rubber mastication, mixing, and then with the skeleton prepared in step A The steel plate is co-extruded, vulcanized, unmoulded, repaired and stored in the double extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com