Mechanized full-automatic integrated equipment for making milk sector

An integrated equipment and fully automatic technology, which is applied in the field of food machinery, can solve the problems of casein fiber breaking, difficulty in ensuring the quality of finished products, and low level of mechanization, and achieve the effect of intelligent data input, large-scale production, and improved appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical contents of the present invention will be further described below in conjunction with the examples; the following examples are illustrative, not restrictive, and the protection scope of the present invention cannot be limited with the following examples.

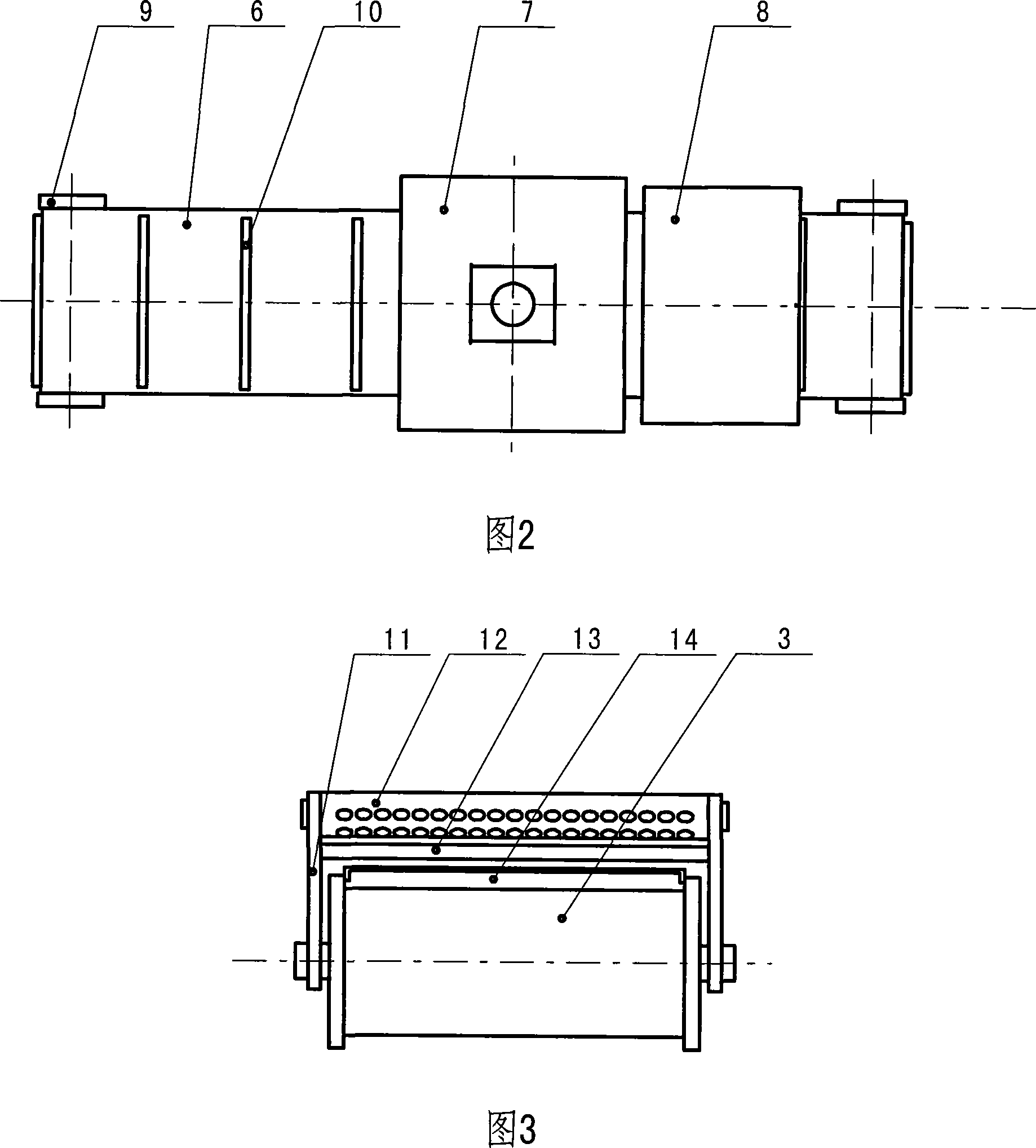

[0026] The mechanized integrated equipment for milk fan processing is composed of a clot extruder 1, a motorized rotating shaft roller stretching machine, and a processing combination machine. Wherein the clot extruder borrowed another patent of the applicant for this patent——a heat stretching machine (patent number: 200620027250.5) for making pizza cheese in situ cleaning, its structure can refer to the description of this patent, in This will not be repeated here. The structure of the other components is:

[0027] Motorized rotating shaft roller stretching machine:

[0028] This motorized rotating shaft roller stretching machine is composed of a motor (not shown in the figure), a rotating shaft 5, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com