Combustion method and system

A combustion system and burner technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of inability to quickly adjust operating parameters, optimal NOx reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

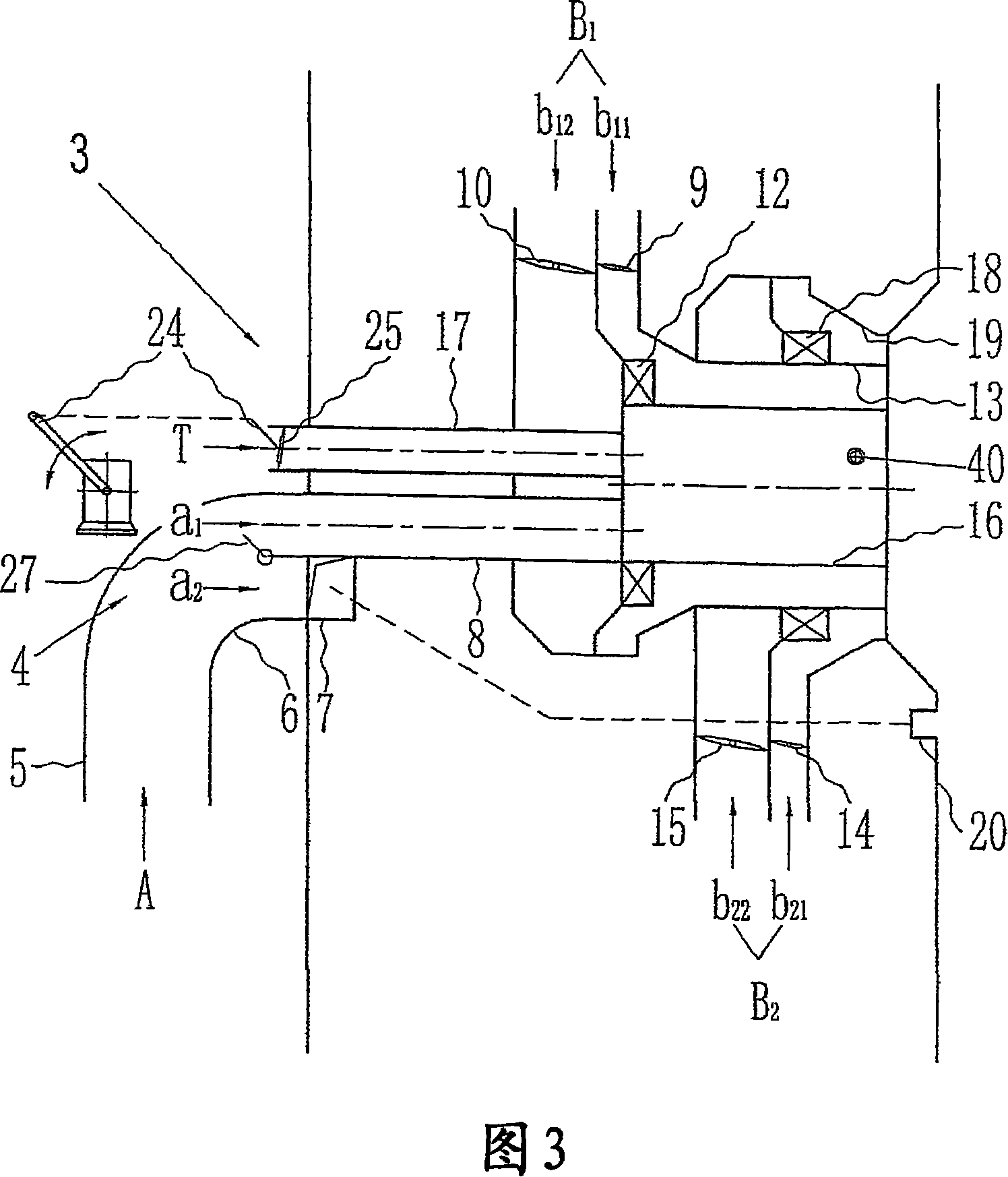

[0032] The following preferred embodiments of the invention are sometimes discussed in terms of coal combustion and air as the gaseous carrier and oxidant. The technique is applicable to any other pulverized solid fuel and any other gaseous carrier. The invention will be illustrated with the aid of the drawings, but the description with reference to the drawings is not intended to limit the scope of the invention.

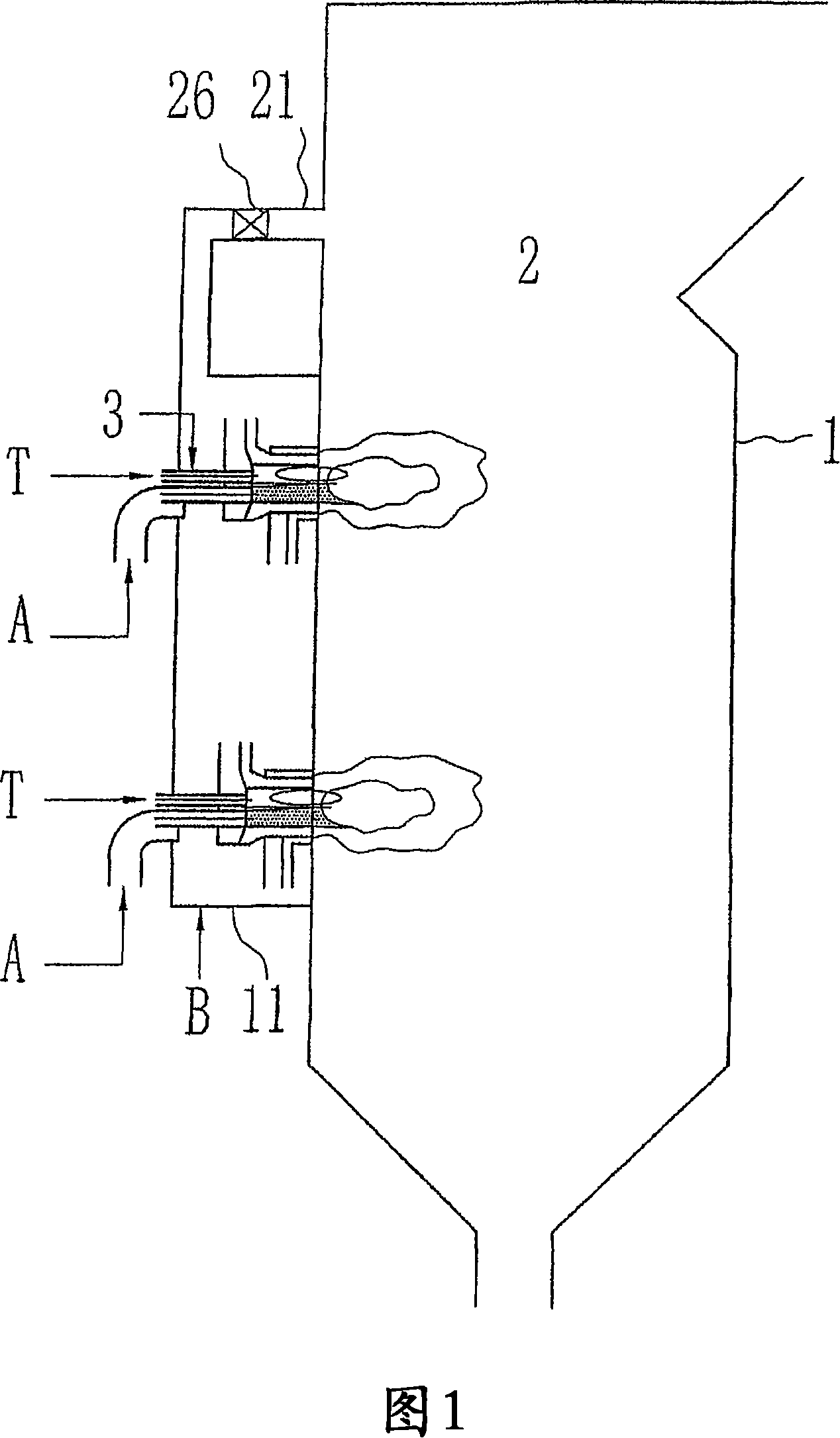

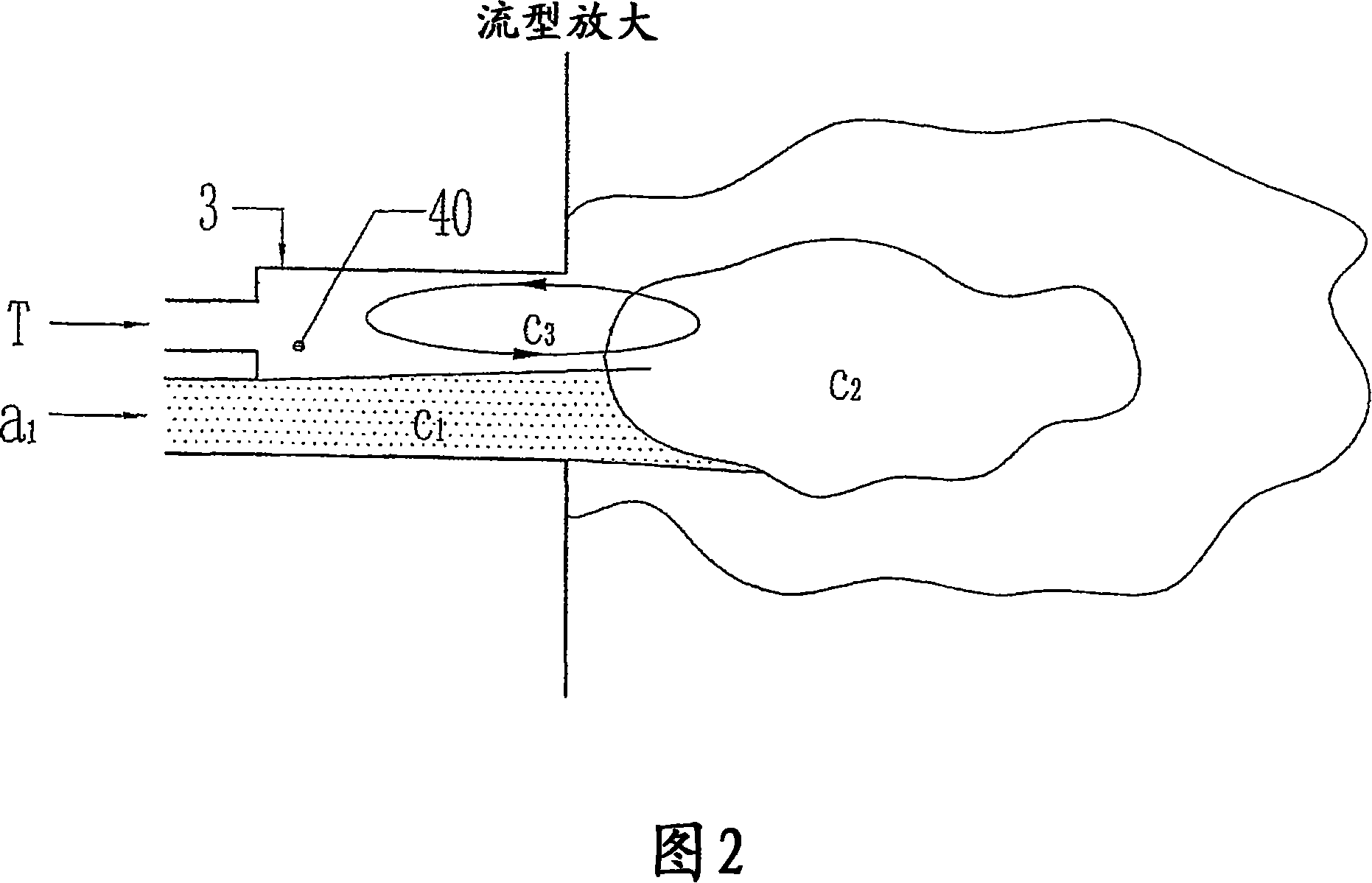

[0033] 1 to 4 show a preferred embodiment of a swirl burner according to the invention. Certain embodiments of the combustor are described in more detail in FIGS. 4 and 5 . The invention also includes once-through burners in which the secondary flow and / or other flows are supplied into the combustion chamber in a once-through manner.

[0034] FIG. 1 shows a combustion system comprising a burner 3 and a combustion device 1 with a chamber 2 . The combustion device of the present invention may be any device within which combustion occurs. Typical combustion device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com