Down hole physical upgrading of heavy crude oils by selective energy absorption

A crude oil, electromagnetic energy technology, applied in wellbore/well components, isolation devices, production fluids, etc., can solve the problem that the visbreaking process cannot work in situ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

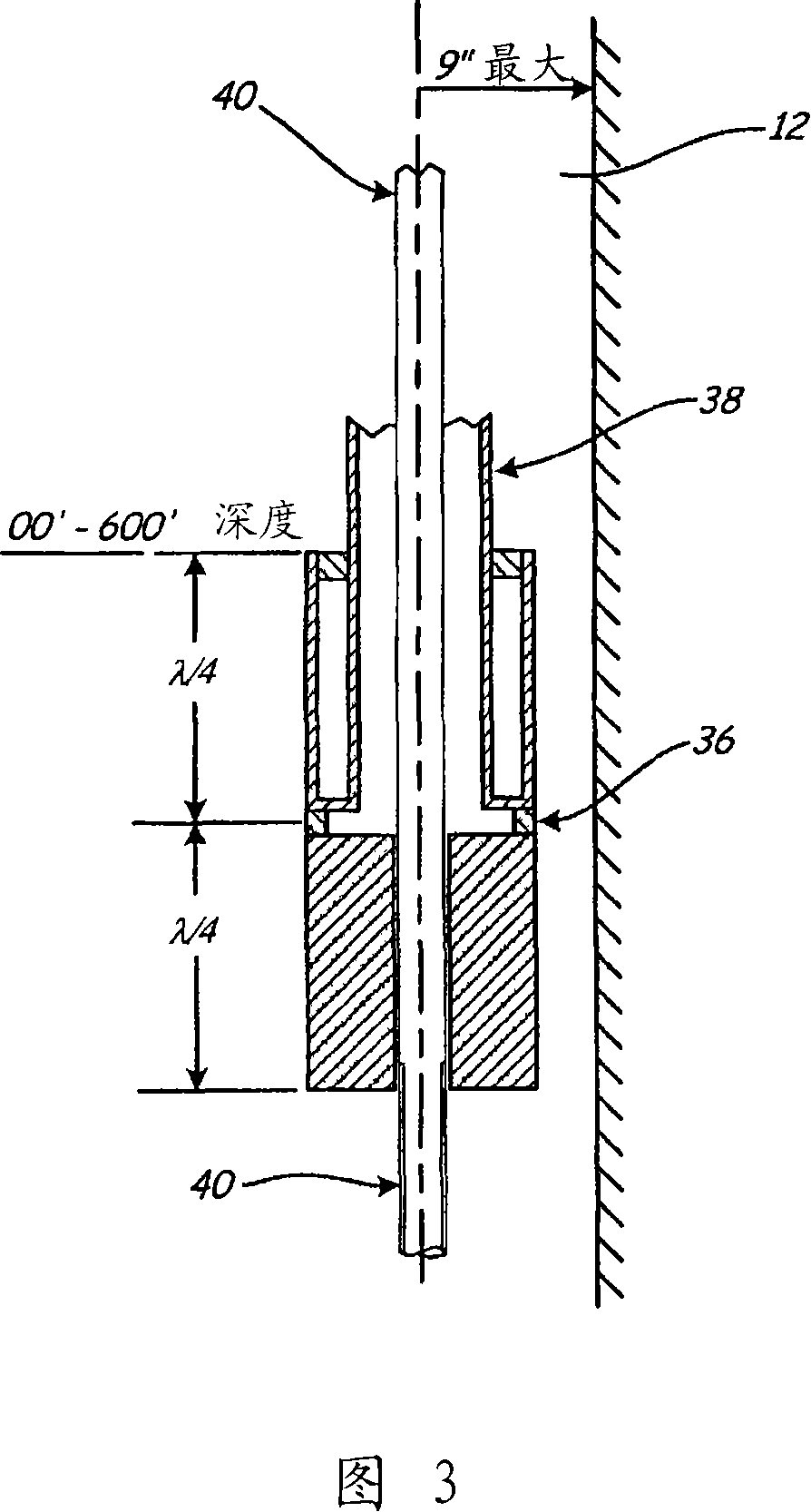

[0018] Electromagnetic energy can be applied in situ to heavy crude oil using various forms of downhole electromagnetic structures. The appropriate configuration for any particular application will depend on factors including depth, uniformity of heat, and minimization of unsaturated hydrocarbon generation and coking.

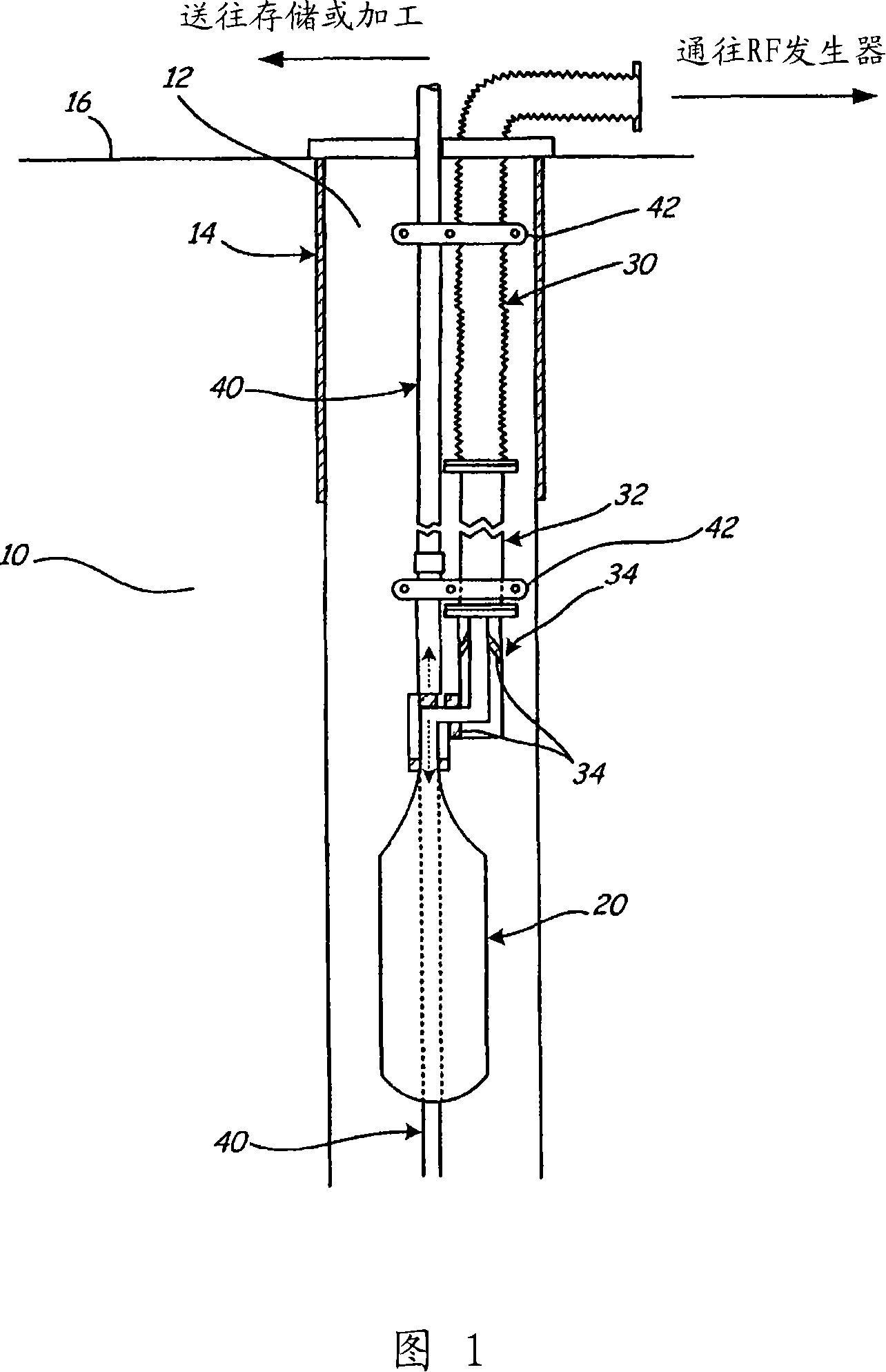

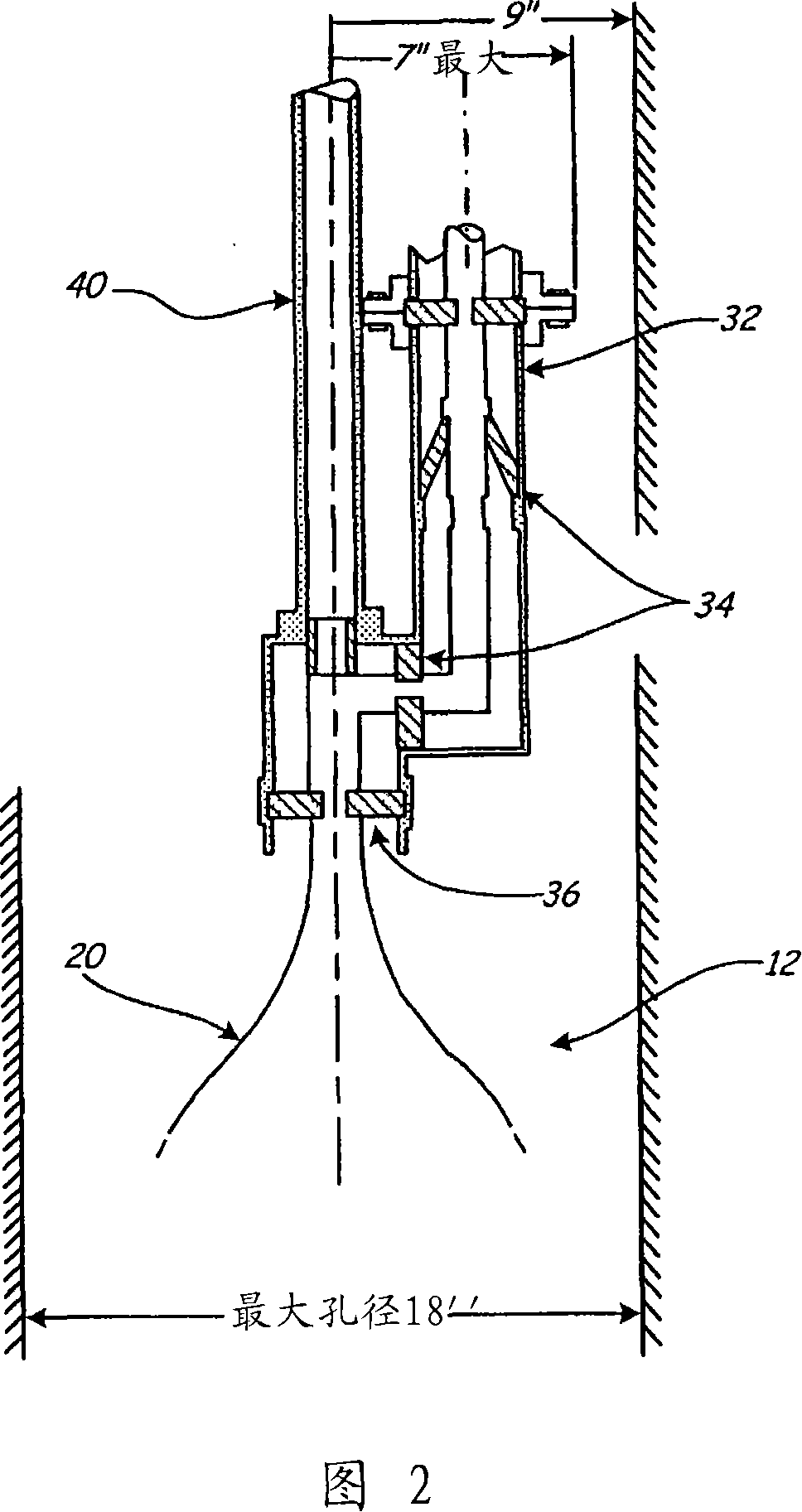

[0019] Figure 1 is a perspective view of a single borehole radial applicator. Applicator system 10 is placed within wellbore 12 . Wellbore 12 is supported by casing 14 . Electromagnetic energy is then applied to the heavy crude oil near the wellbore 12 using the applicator system 10 .

[0020] Applicator structure 20 is a transmission line retort. For reference, a typical applicator 20 is approximately 70 feet in length. In a typical configuration, applicator 20 may be placed in borehole 12 100-600 feet underground. Radio frequency ("RF") energy is provided to applicator 20 using an RF generator (not shown). The RF generator is connected to the applicator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com