Through-hole etching method

A technology of through-hole etching and etching gas, which is applied in the directions of optics, instruments, and opto-mechanical equipment. Stability, effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

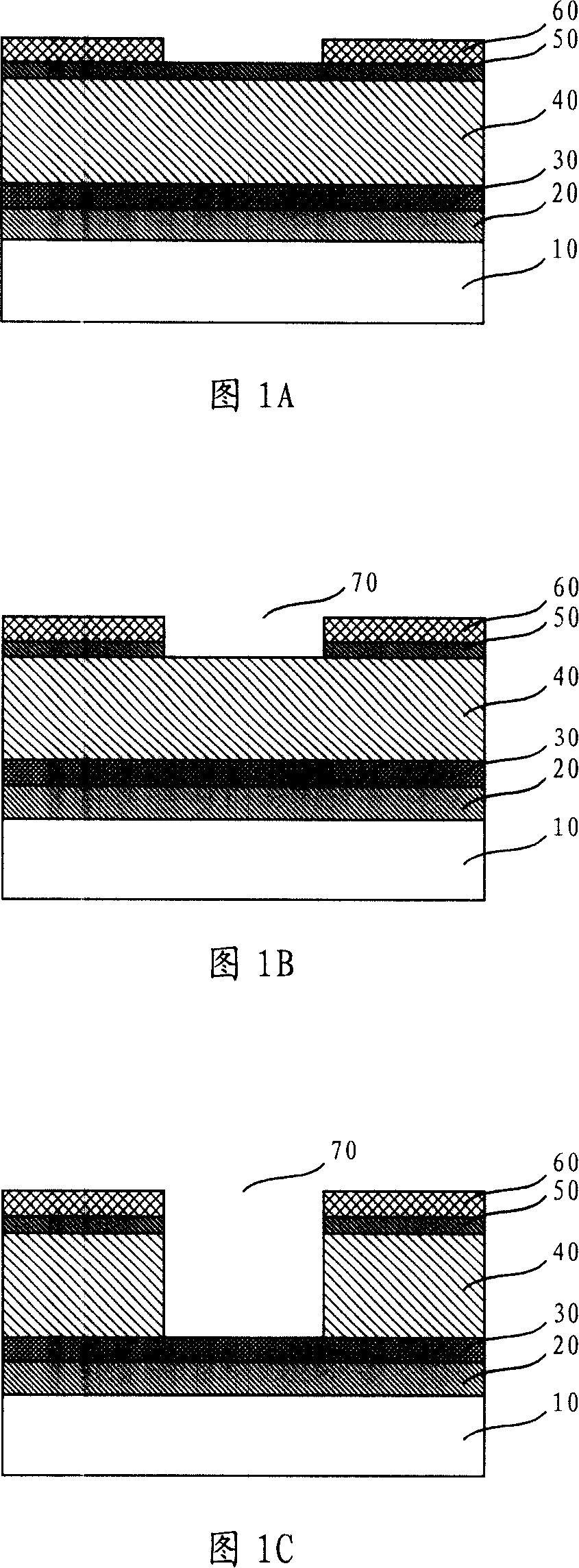

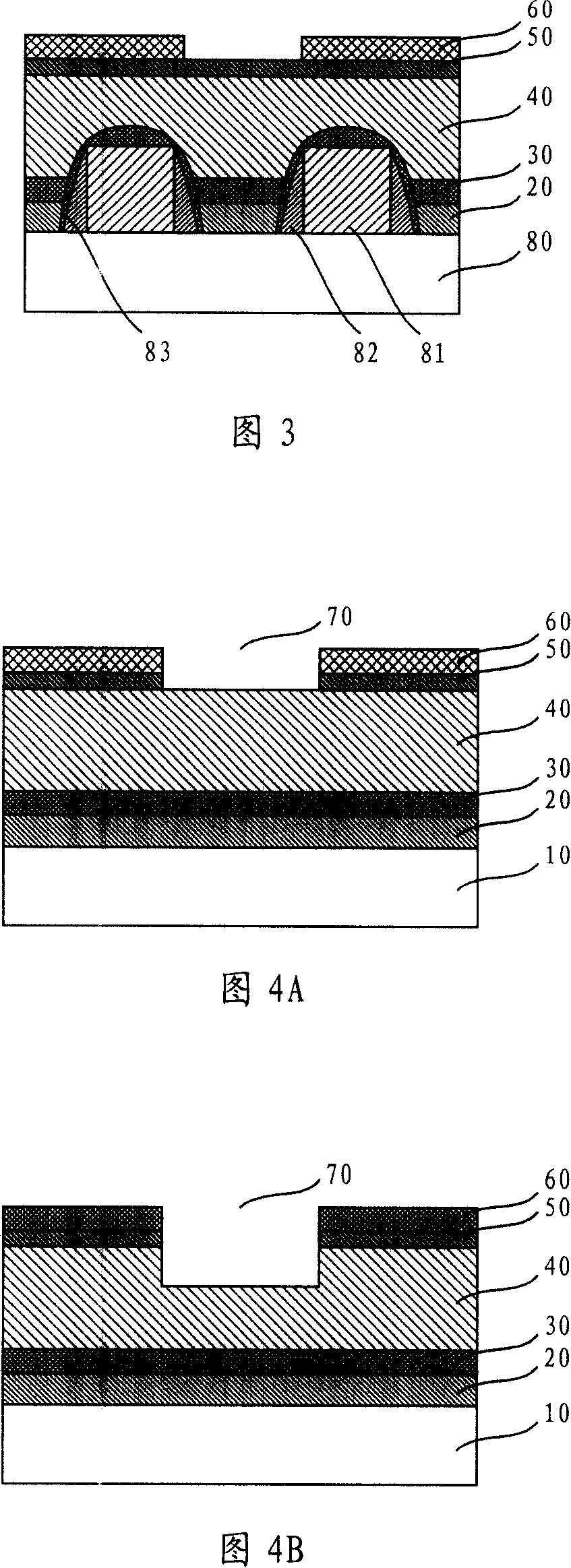

[0025] 4A to 4E are schematic diagrams illustrating a through-hole etching method of the first embodiment of the method of the present invention. As the first embodiment of the present invention, the specific steps of applying the method of the present invention to etch the through-hole of the inter-metal dielectric layer are as follows:

[0026] First, as shown in FIG. 4A , a via hole etching structure is formed on the surface of the underlying metal 10 , and the anti-reflection coating 50 is etched.

[0027] The etched structure of the through hole 70 includes an adhesive layer 20 , an etch stop layer 30 , a dielectric layer 40 , an antireflection coating 50 and a patterned photoresist layer 60 deposited in sequence. The bonding layer 20 is a transition layer that enhances the connection effect between the semiconductor substrate and the connection material in the through hole; the etching stop layer 30 is an etching stop layer; the dielectric layer 40 includes an insulating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com