Application of

An absorptiometry, molybdenum concentrate technology, applied in the field of analytical chemistry, can solve the problems of shortening the test cycle, cumbersome steps, time-consuming and laborious, and reducing the cost of the test, and achieves the effect of shortening the test period, reducing the cost and improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

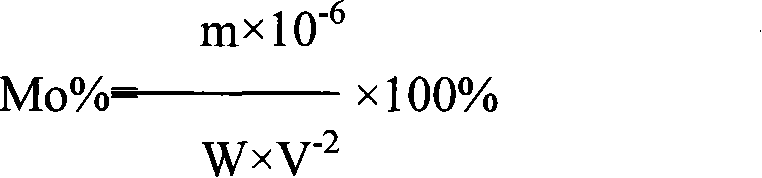

[0021] This test method is based on the following experiments:

[0022] 1. Preparation of reference solution:

[0023] The preparation standard of the reference solution is that the absorbance of the solution to be tested is about A=0.434, and the relative reading error is the smallest at this time. According to the content of molybdenum in the molybdenum concentrate in this method, it is determined that the solution containing molybdenum 10ug / ml is the reference solution for the test after many tests. For the preparation method, see the section on the drawing of the standard curve.

[0024] 2. Preparation of main reagents:

[0025] a. Sulfuric acid-copper sulfate-oxalic acid mixed solution: take 1000ml of concentrated sulfuric acid and slowly add it to 1000ml of water under constant stirring, add 2g of oxalic acid, 20ml of copper sulfate solution containing 20g / ml of copper, cool it, transfer it into a 2000ml reagent bottle and shake well for later use .

[0026] b. Thiour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com