Immobilized biological agent and method for degrading bice green contamination of cultivation aquifer

A technology of immobilized microorganisms and preparations, applied in biological water/sewage treatment, immobilized on/in organic carriers, chemical instruments and methods, etc., can solve problems such as predation by aquatic organisms and difficulty in achieving satisfactory repair effects, etc. To achieve the effect of ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

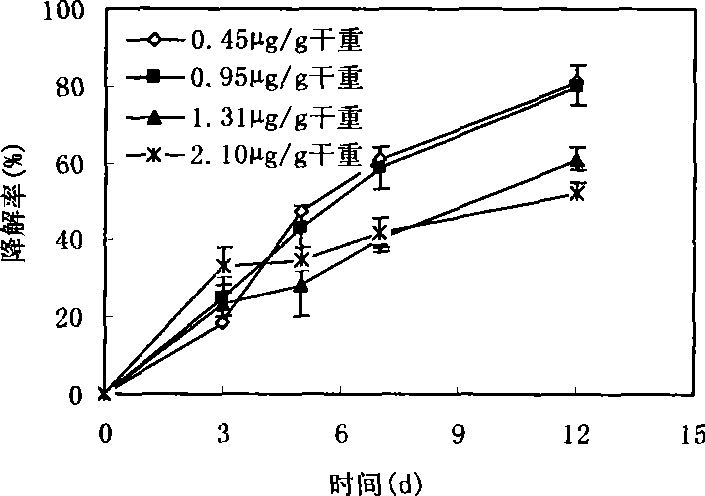

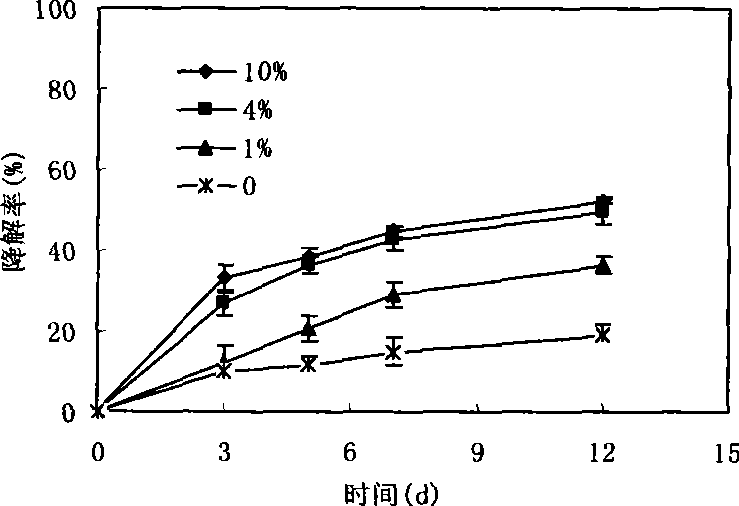

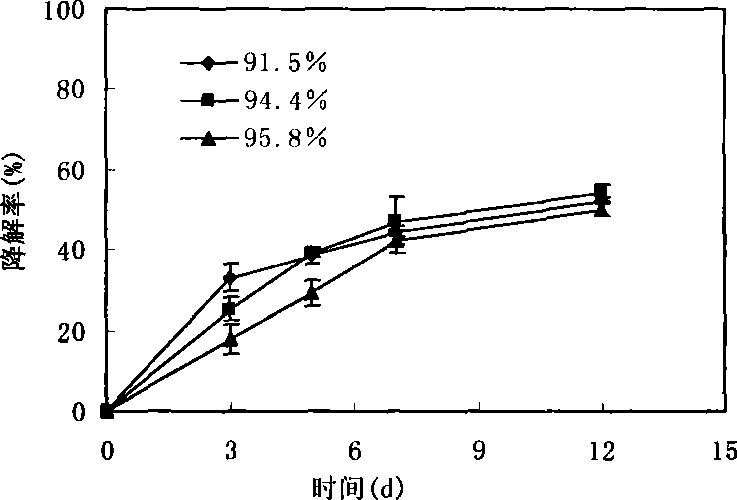

[0023] Bacterial classification is inoculated in rich culture medium (medium composition is: in 1000ml: glucose 5g; KH 2 PO 4 1g; K 2 HPO 4 1g; NH 4 NO 3 1g; MgSO 4 ·7H 2 O10mg; CaCl 2 0.5mg; yeast extract 5g; peptone 10g; adjust pH to 7.0-7.5; 121°C, 103kPa, 20min after damp heat sterilization), 35°C, 150rpm enrichment culture for 24h, centrifuge, wash with phosphate buffer, and concentrate Add the bacterial suspension into the aqueous solution containing sodium alginate, so that the final concentration of sodium alginate is 2%, and the bacterial content is 1.0 g / L. The mixture was added dropwise to 5% CaCl 2 solution, fixed at 4°C for 16h. Finally, after washing with phosphate buffer solution, the final immobilized microorganism preparation is obtained, the bacteria content is 0.188% (m / m), and the diameter of the ball is 2-3mm. The preparation is inserted into 2 mg / L malachite green aqueous solution according to 2% (m / m) inoculum amount, and after 6 days, the degr...

Embodiment 2

[0025] The bacteria were inoculated in the enrichment medium (the composition of the medium was the same as in Example 1) for 24 h at 35° C. and 150 rpm for enrichment, centrifuged, washed with phosphate buffer, and the obtained concentrated bacterial suspension was added to an aqueous solution containing sodium alginate to make the final The concentration of sodium alginate is 2%, and the bacteria content is 1.5g / L. The mixture was added dropwise to 5% CaCl 2 solution, fixed at 4°C for 16h. Finally, after washing with phosphate buffer solution, the final immobilized microorganism preparation is obtained, the bacteria content is 0.282% (m / m), and the diameter of the ball is 2-3mm. The preparation is inserted into 2mg / L malachite green aqueous solution according to 2% (m / m) inoculum amount, and after 6 days, the degradation rate of malachite green is 89.2%.

Embodiment 3

[0027] The bacteria were inoculated in the enrichment medium (the composition of the medium was the same as in Example 1) for 24 h at 35° C. and 150 rpm for enrichment, centrifuged, washed with phosphate buffer, and the obtained concentrated bacterial suspension was added to an aqueous solution containing sodium alginate to make the final The concentration of sodium alginate is 2%, and the bacteria content is 2.0g / L. The mixture was added dropwise to 5% CaCl 2 solution, fixed at 4°C for 16h. Finally, after washing with phosphate buffer solution, the final immobilized microbial preparation is obtained, with a bacterial content of 0.375% (m / m), and a ball diameter of 2-3mm. The preparation is inserted into 2 mg / L malachite green aqueous solution according to 2% (m / m) inoculum amount, and after 6 days, the degradation rate of malachite green is 88.7%. It can be seen that the preparation with 0.282% bacteria content has the best degradation effect on malachite green.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com