Process for producing ethylene by ethanol dehydration

A technology of ethanol and ethylene, which is applied in the field of selective dehydration to generate ethylene, which can solve the problems of increasing the load of the sewage treatment system, lack of too much innovation and change, and blockage of the alkali washing tower, so as to achieve enhanced washing effect, improve processing capacity, and feed Effect of temperature and flow reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

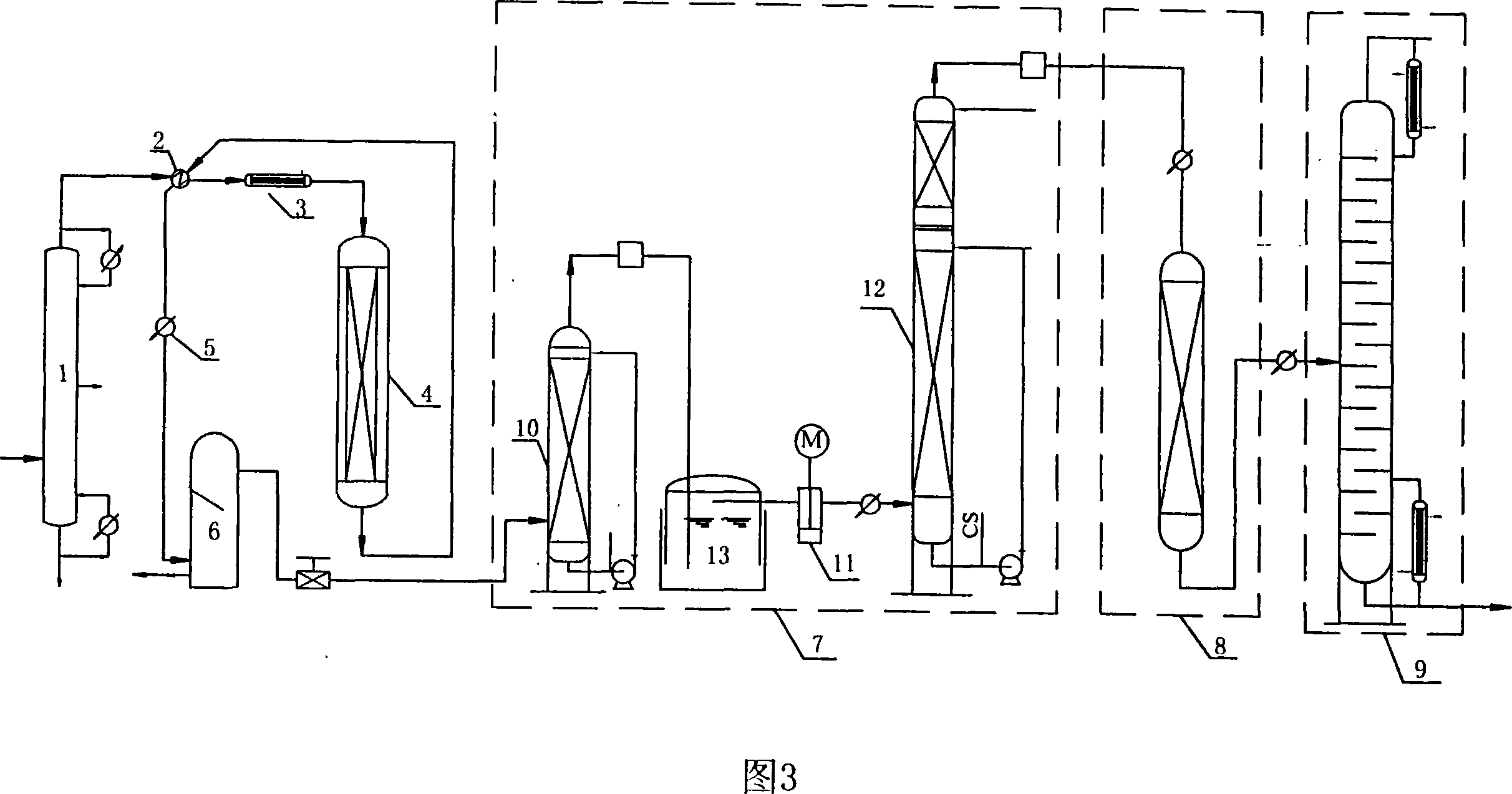

[0038] (1) Feed the fermented alcohol mash into the distillation system 1 composed of distillation towers, control the ethanol raw material whose ethanol outlet concentration is 55% from the distillation tower, the ethanol raw material obtained is not cooled, and is directly transported to the follow-up section with material pipelines, The material conveying pipeline is wrapped with thermal insulation material;

[0039] (2) The ethanol-water mixed vapor from the distillation system 1 passes through the gas-gas heat exchange device 2 and the heating device 3 to raise the temperature to 250°C;

[0040] (3) The ethanol-water mixed steam after the temperature rise enters the gas-solid catalytic reactor 4 to carry out the catalytic reaction; an isothermal tubular reactor with a tube diameter of 32mm, the heating medium is molten salt, and the catalyst adopts HZSM-5 molecular sieve, The bulk density of the molecular sieve is 0.65kg / L, the filling height in the reaction tube is 2600m...

Embodiment 2

[0046] (1) Feed the fermented alcoholic mash into distillation system 1 composed of distillation towers. Distillation system 1 adopts a double-tower rectification process to obtain ethanol-water mixed vapor with a concentration of 95% from the second rectification tower, and the obtained ethanol -Water mixed steam is not cooled, and is directly transported to the catalytic ethylene production section through material pipelines, and the material delivery pipelines are wrapped with thermal insulation materials;

[0047] (2) The ethanol-water mixed vapor from the distillation system 1 passes through the gas-gas heat exchange device 2 and the heating device 3 in sequence to raise the temperature to 350°C;

[0048] (3) the ethanol-water mixed vapor after heating enters gas-solid catalytic reactor 4 and carries out catalytic reaction, adopts multistage adiabatic bed reactor, bed diameter 800mm; Catalyst is active alumina, and the bulk density of catalyzer is 0.78kg / L, the filling h...

Embodiment 3

[0054] (1) The fermented alcohol mash is passed into a distillation system 1 composed of distillation towers, and the distillation system 1 adopts a double-tower rectification process. The second rectification tower obtains ethanol-water mixed vapor with a concentration of 95%, and the obtained ethanol-water mixed vapor is not cooled, but is directly transported to the catalytic ethylene production section through material pipelines, and the material delivery pipelines are wrapped with thermal insulation materials;

[0055](2) The 95% ethanol-water mixed vapor from the distillation system 1 is evenly mixed with the water vapor at 127°C and 0.25 MPa in a molar ratio of 275:41 (mass ratio is 7.38:100) through a gas jet mixing device , to obtain a concentration of 75% ethanol-water mixed gas;

[0056] (3) The ethanol-water mixed gas with a concentration of 75% is heated up to 280° C. through the heating device 3;

[0057] (4) The ethanol-water mixed vapor after heating enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com