Method for knitting craftsman furniture

A furniture and craftsmanship technology, applied in sugarcane machining, mechanical equipment, etc., can solve problems such as lack of innovation in methods, and achieve the effect of high added value, smooth lines, and simple weaving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

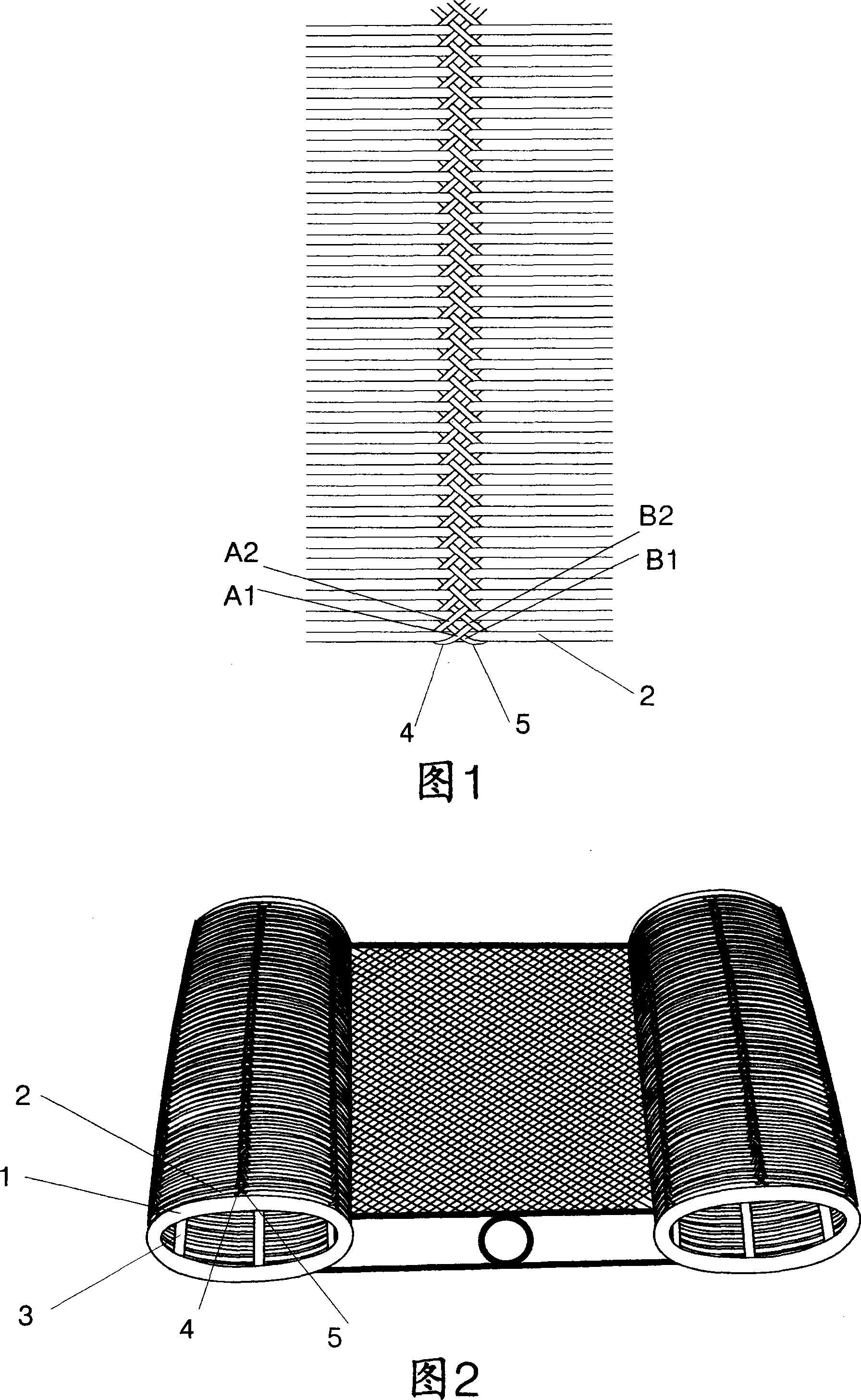

[0015] Referring to Fig. 1, a weaving method for craft furniture is provided, including a frame 1 and a strip material 2, the frame 1 is a hollow shape made of a wooden strip with a certain hardness, and a plurality of support bars 3 are distributed in parallel on the frame 1; The strip-shaped material 2 is a plurality of relatively flexible rattans arranged in parallel, and the strip-shaped material 2 is nailed on a plurality of branch strips 3 along the vertical direction with the branch strips 3 in sequence. The upper surfaces of all intersections are beautifully decorated with two decorative strips 4-5 cross-woven. The above-mentioned frame 1 can also be made of rattan or iron bars with a certain hardness, and the strip material 2 can also be made of hemp rope, paper rope, or rubber strips.

[0016] Fold the two decorative strips 4 to 5 in half into sections A1, A2, B1, and B2. A1 and B1 cross in an X shape above the first rattan. The intersection covers the nail head, and...

Embodiment 2

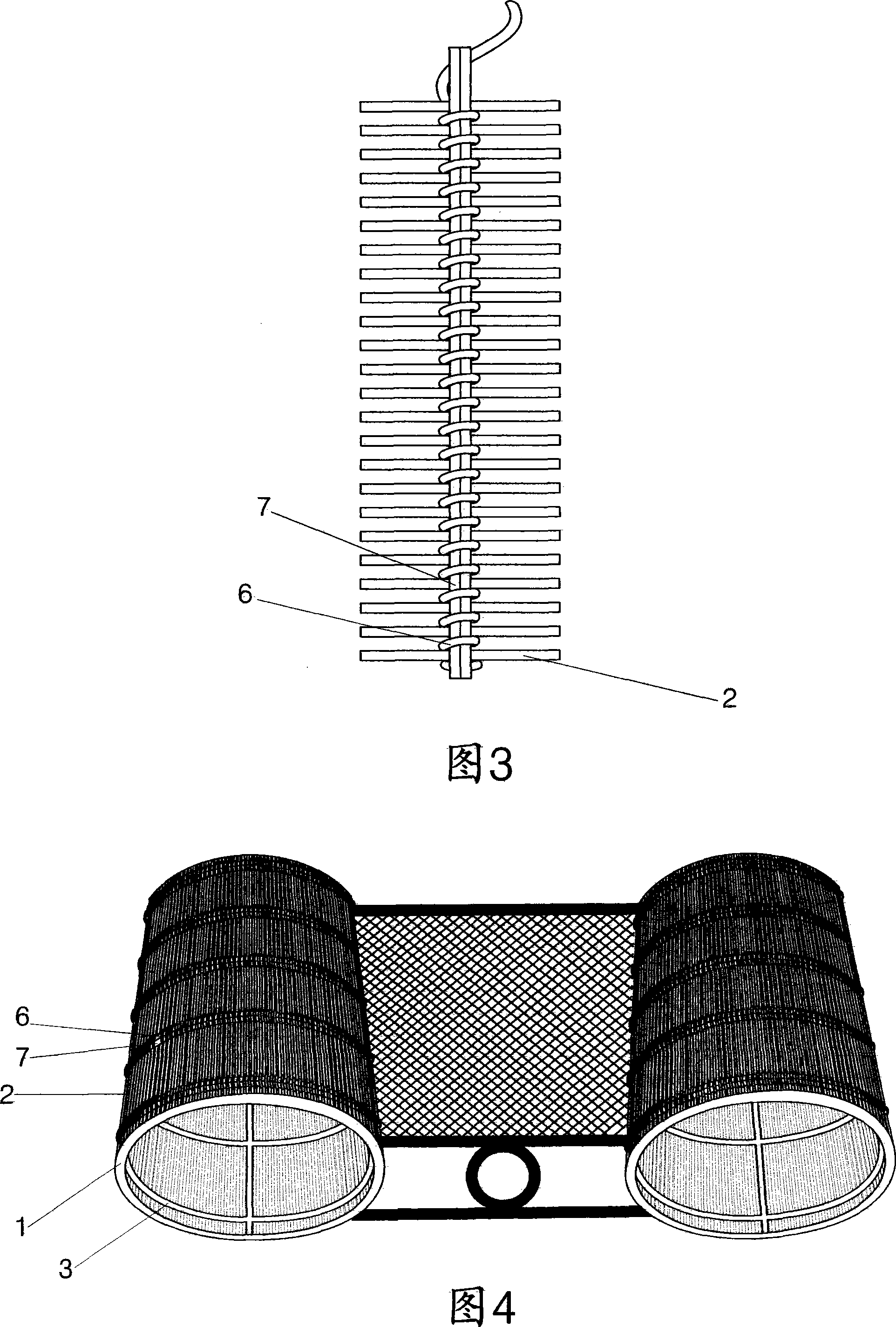

[0019] Referring to Fig. 3, a weaving method for craft furniture is provided, including a frame 1 and a strip material 2, the frame 2 is a hollowed-out shape made of iron material, and there are a plurality of branches 3 distributed in parallel on the frame 2, and the strip material 2 is A number of fiber ropes made of hemp fibers arranged in parallel, each strip material 2 is wound and fixed on the branch 3 by binding rope 6 along the direction perpendicular to the branch 3 . The frame 2 can also be made of other metal materials with a certain hardness, and the strip material 2 can also be made of grass fibers.

[0020] The two ends of each strip material 2 are fixed on both sides of the frame 2, and the whole strip material 2 is erected on the upper surface of a plurality of support bars 3, and the upper surface of the strip material 2 is arranged along the extending direction of each support bar 3. Two juxtaposed compression ropes 7, the binding rope 6 helically alternately...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com