Supply power adjusting apparatus and semiconductor manufacturing apparatus

A technology for power regulators and manufacturing devices, applied in semiconductor/solid-state device manufacturing, output power conversion devices, electric heating devices, etc., can solve problems such as power supply changes and load change stability deterioration, and achieve excellent temperature responsiveness and use Good convenience and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] As a result of the research to achieve the above purpose, the inventors found the most suitable technical solution for the above purpose when considering the power consumption and high-speed switching of the IGBT, and then obtained that if the AC voltage is directly switched by the IGBT, there is no need to have a rectification circuit. insights, leading to the creation of the present invention.

[0028] One embodiment of the power supply conditioner of the present invention will be described below.

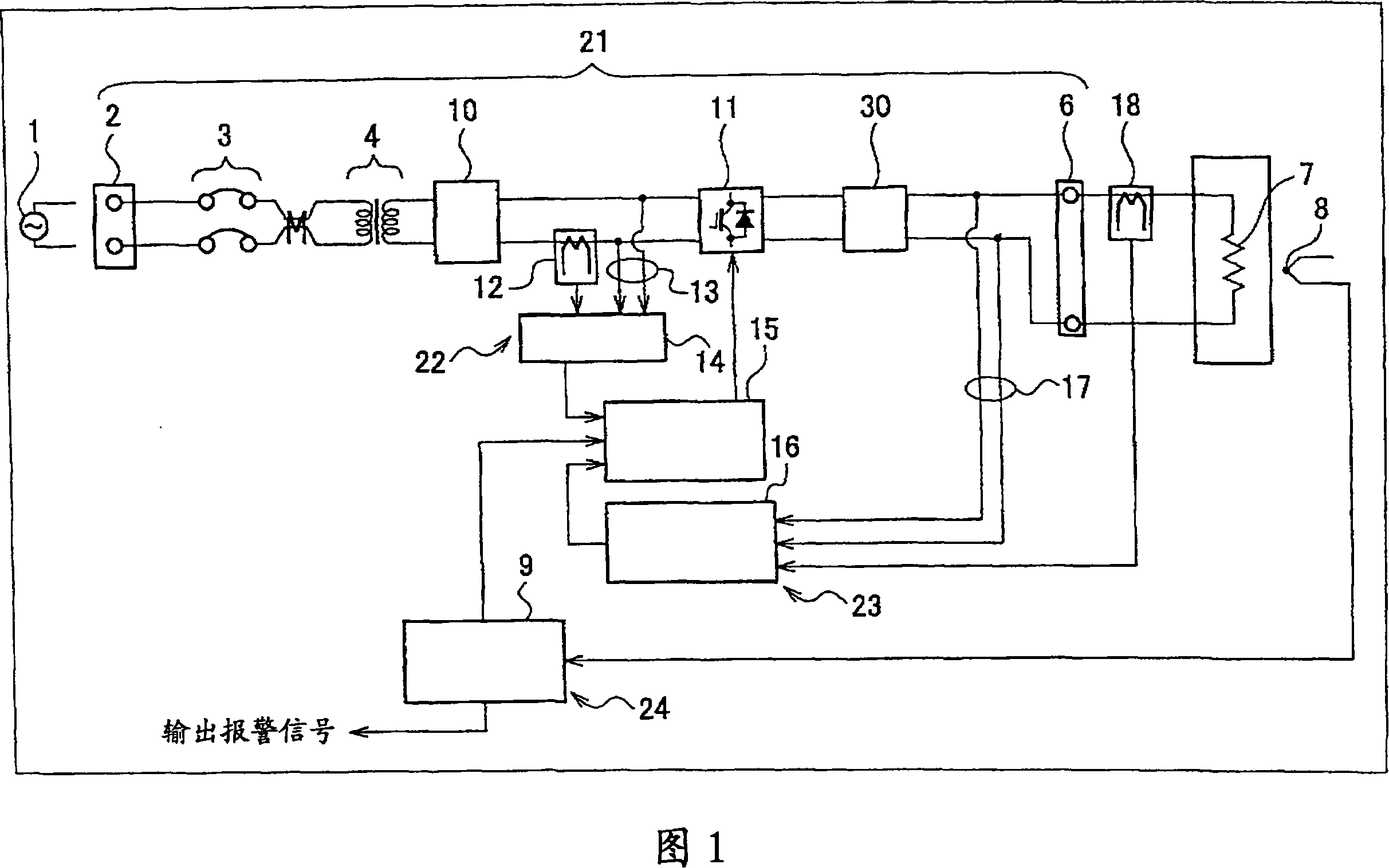

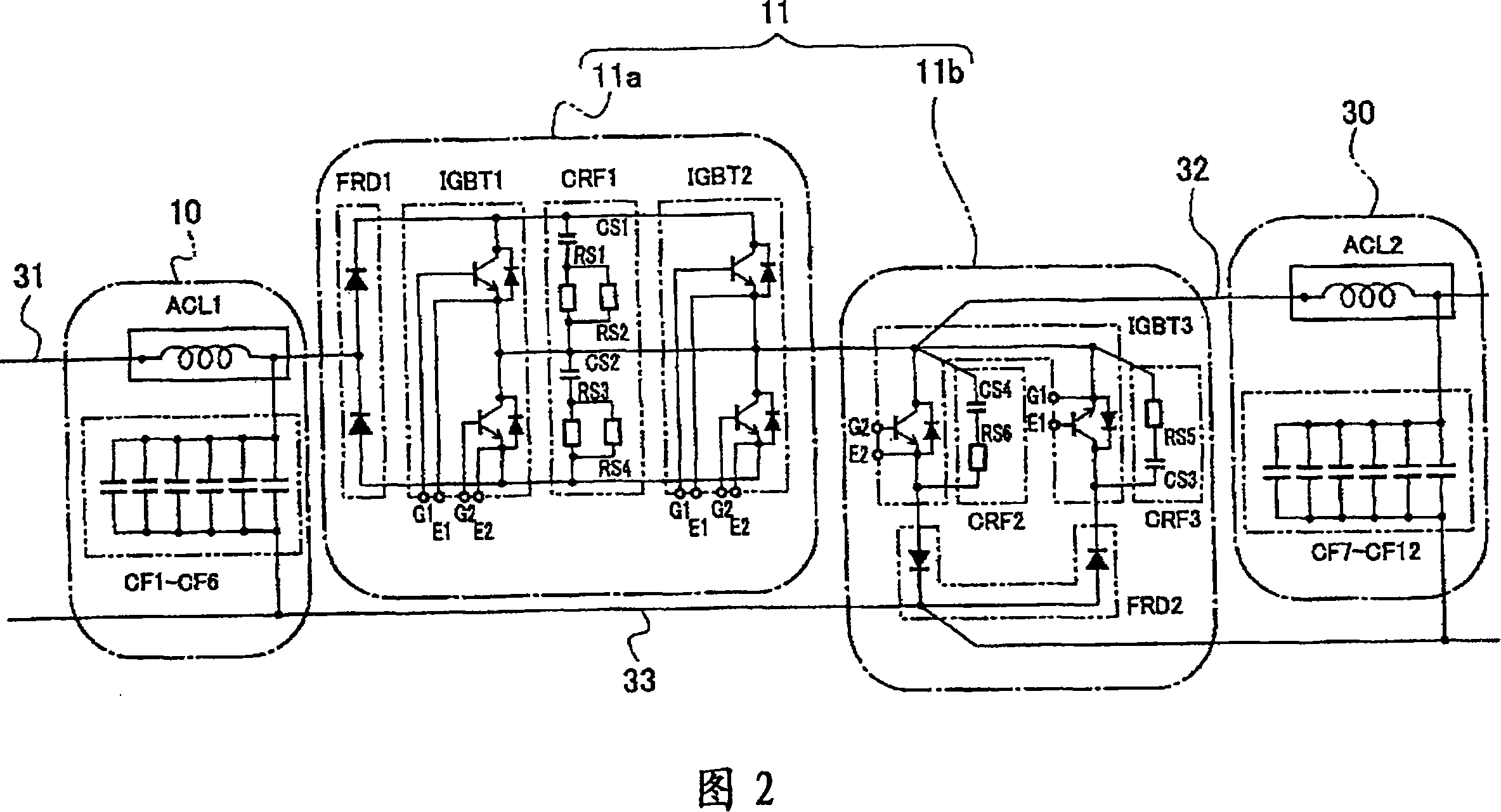

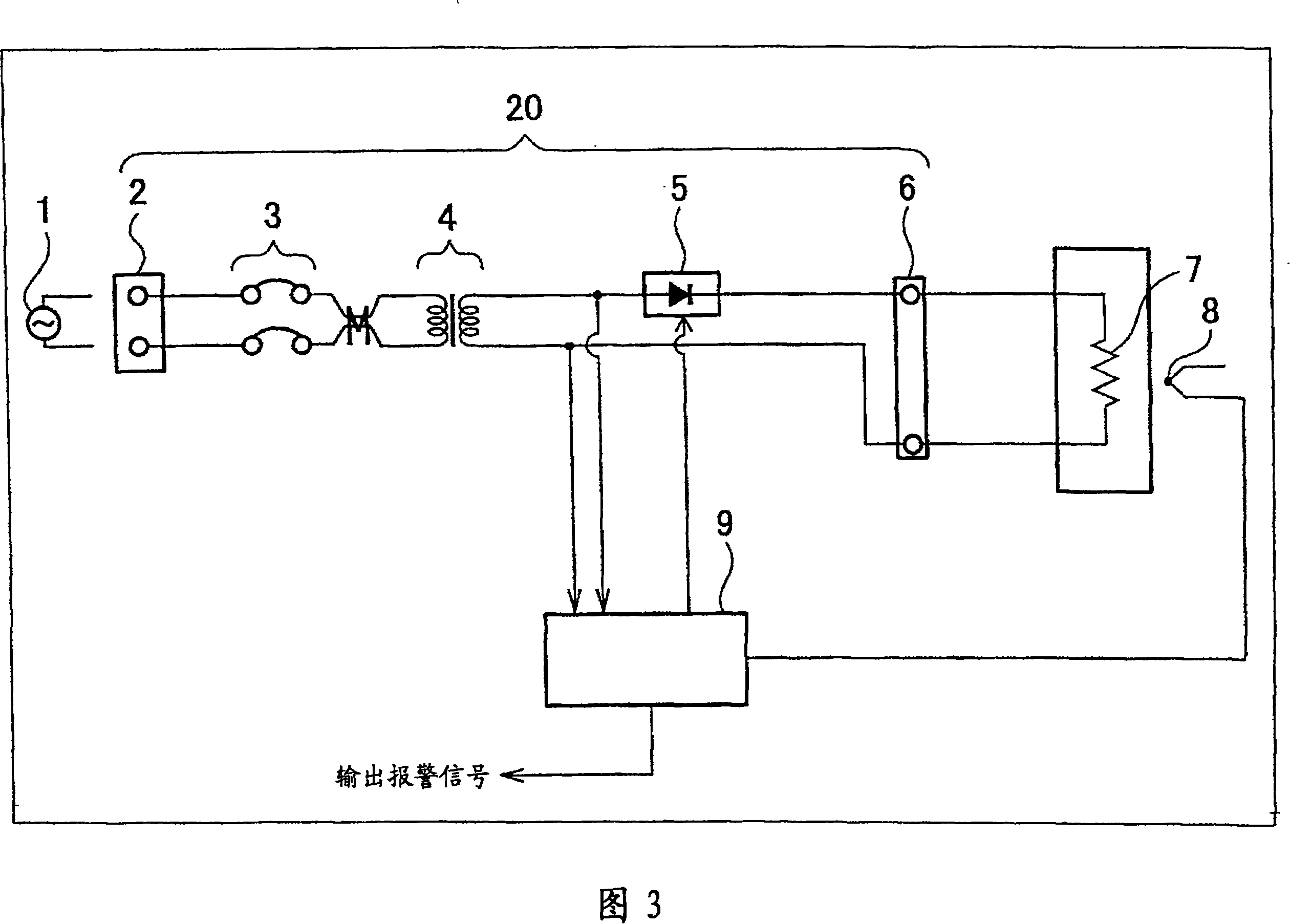

[0029] In the power supply conditioner of this embodiment, the output of the inverter performing high-speed switching operation is used as power supply to the heater, and an IGBT, which is a high-speed switching power control element, is used as a device of the inverter. The AC voltage of the AC power supply is directly switched by the IGBT and the pulse-modulated AC power is supplied to the heater, so that the reactive power is almost zero, thereby effectively utilizing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com