Pulse laser sediment method

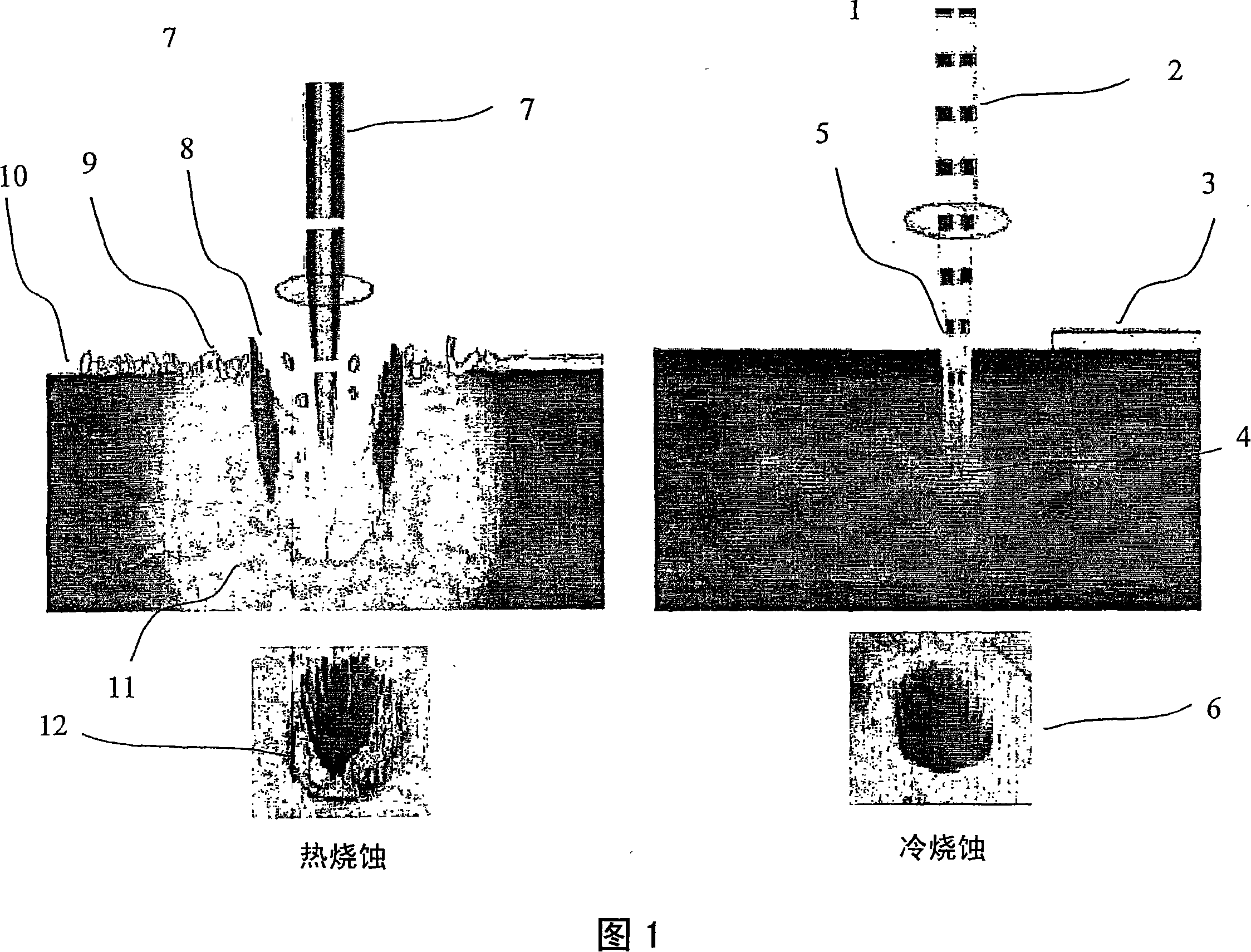

A laser, laser ablation technology, used in optics, optical components, coatings, etc., can solve problems such as low operating speed and low operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0039] The methods and products of the invention are described below without limiting the invention to the examples given. The coating was produced using two X-lase 10W picosecond lasers manufactured by the company Corelase Oy and an X-lase 10W picosecond laser manufactured by the company Corelase Oy. Pulse energy refers to pulse energy incident on an area of 1 square centimeter, which is focused on an area of desired size using optics.

example 1

[0041] In this example, a polycarbonate plate was coated with a diamond coating (sintered carbon). The laser device has the following performance parameters:

[0042] Power: 10W

[0043] Repetition frequency: 4MHz

[0044] Pulse energy: 2.5μJ

[0045] Pulse period: 20ps

[0046] Distance between target and substrate: 35mm

[0047] Vacuum level: 10 -7

[0048] The polycarbonate plate was thus coated with a DLC coating with a thickness of about 200 nm.

example 2

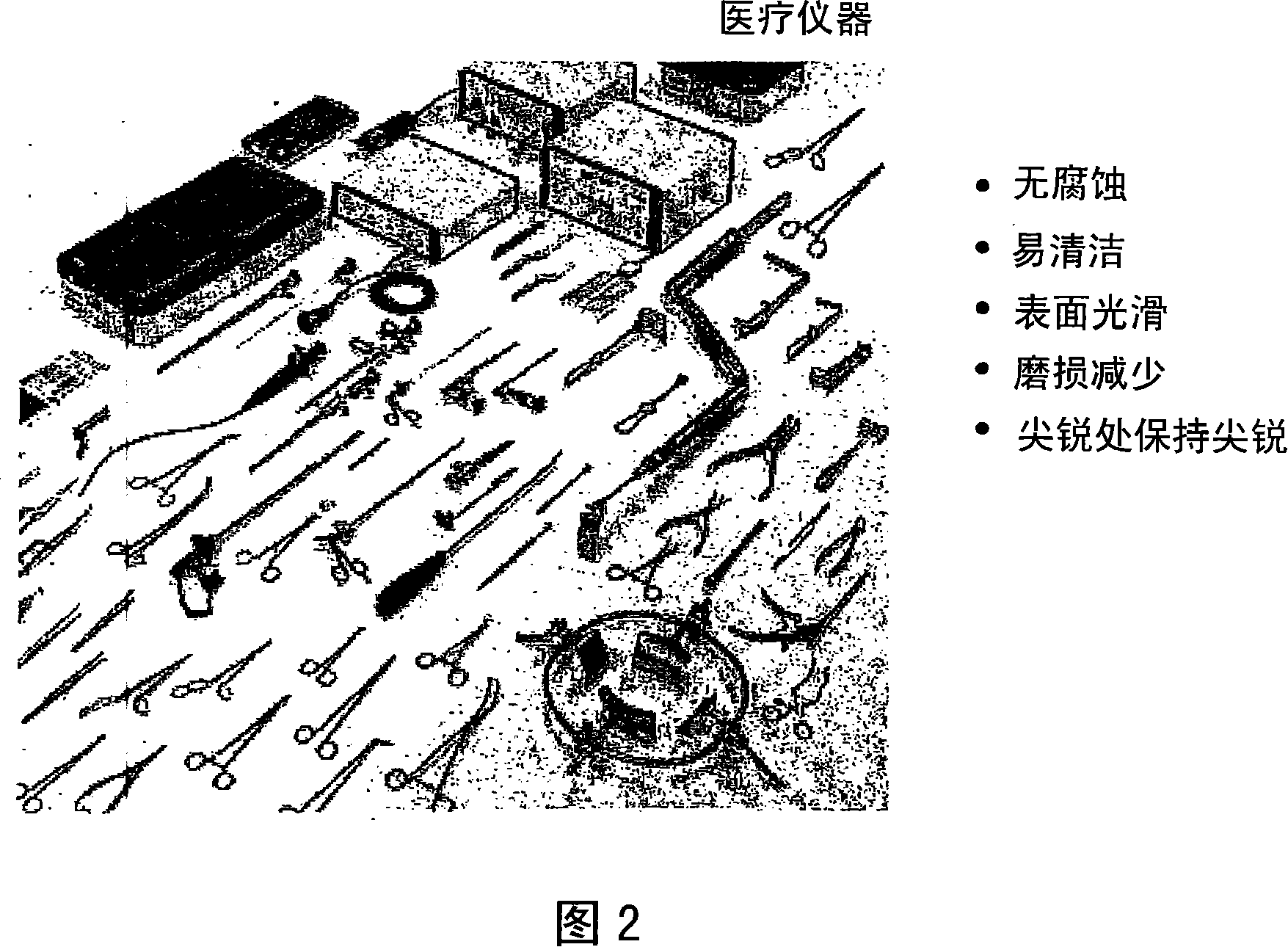

[0050] In this example, bone screws made of roster are covered with a titanium coating. The laser device has the following performance parameters and the coating is produced from ablation sintered carbon:

[0051] Power: 10W

[0052] Repetition frequency: 4MHz

[0053] Pulse energy: 2.5μJ

[0054] Pulse period: 20ps

[0055] Distance between target and substrate: 37mm

[0056] Vacuum level: 10 -8

[0057] The diamond coating (DLC) thus produced has a thickness of about 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse energy | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com