Isolated gate type bipolar transistor

A bipolar transistor and insulated gate technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as increased operating voltage, increased collector-emitter saturation voltage, and easy breakdown, etc., to achieve Effects of preventing breakdown and reducing on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

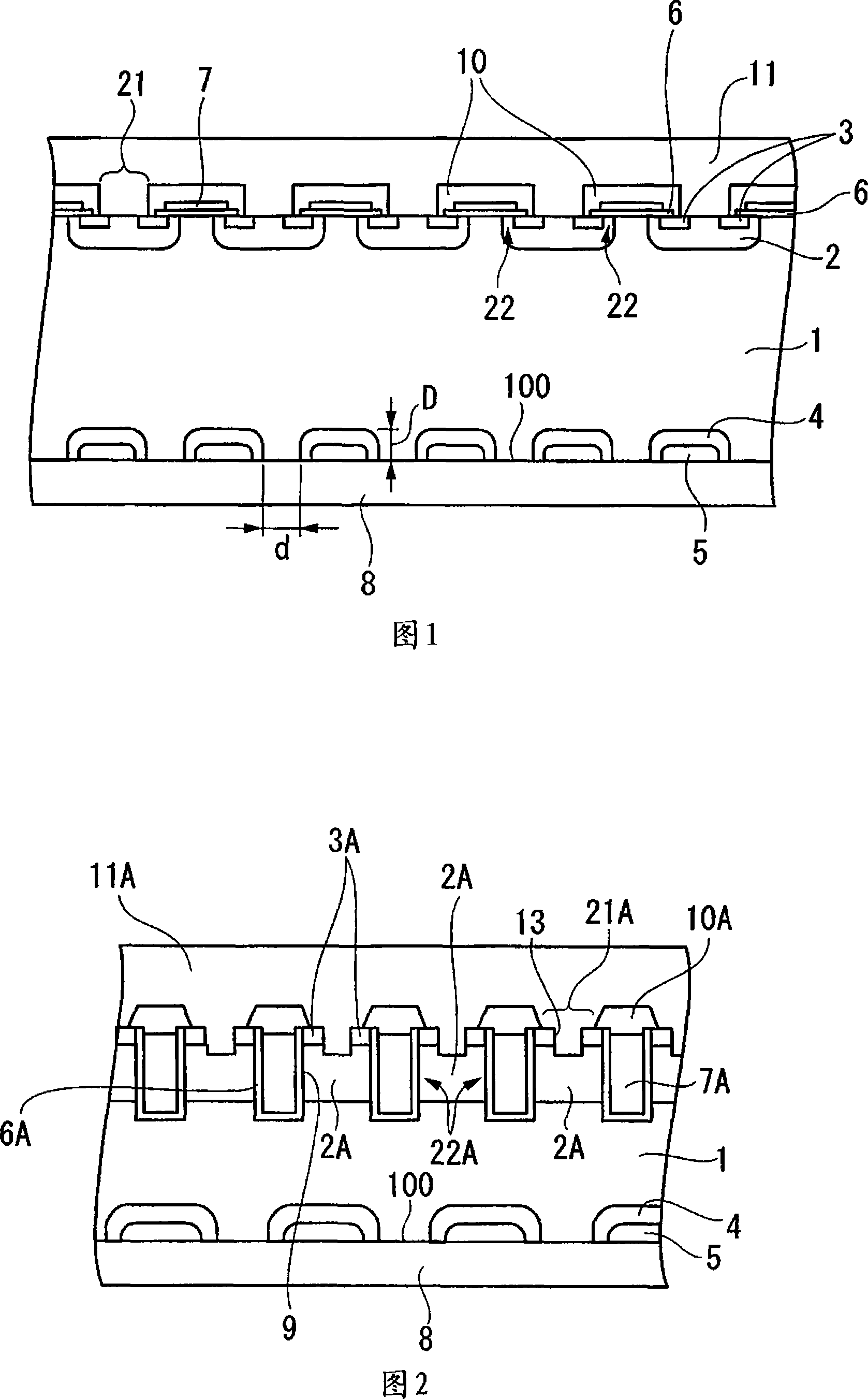

[0032] With reference to the drawings, the insulated gate bipolar transistor according to the first embodiment of the present invention will be described. FIG. 1 is a conceptual diagram showing a cross-sectional structure of an insulated gate bipolar transistor according to a first embodiment of the present invention.

[0033] In FIG. 1, the insulated gate bipolar transistor of this embodiment includes a semiconductor substrate having an N-type base region 1, a P-type base region 2, an emitter region 3, a buffer region 4, and a collector region 5.

[0034] The N-type base region 1 is an N-type semiconductor region (first conductivity type semiconductor region) in which N-type impurities (for example, P: phosphorus, As: arsenic, etc.) are diffused.

[0035] The P-type base region 2 is a P-type semiconductor region in which P-type impurities (for example, B: boron, etc.) are diffused to the top surface (one main surface side) of the N-type base region 1 and formed in stripes.

[003...

no. 2 approach

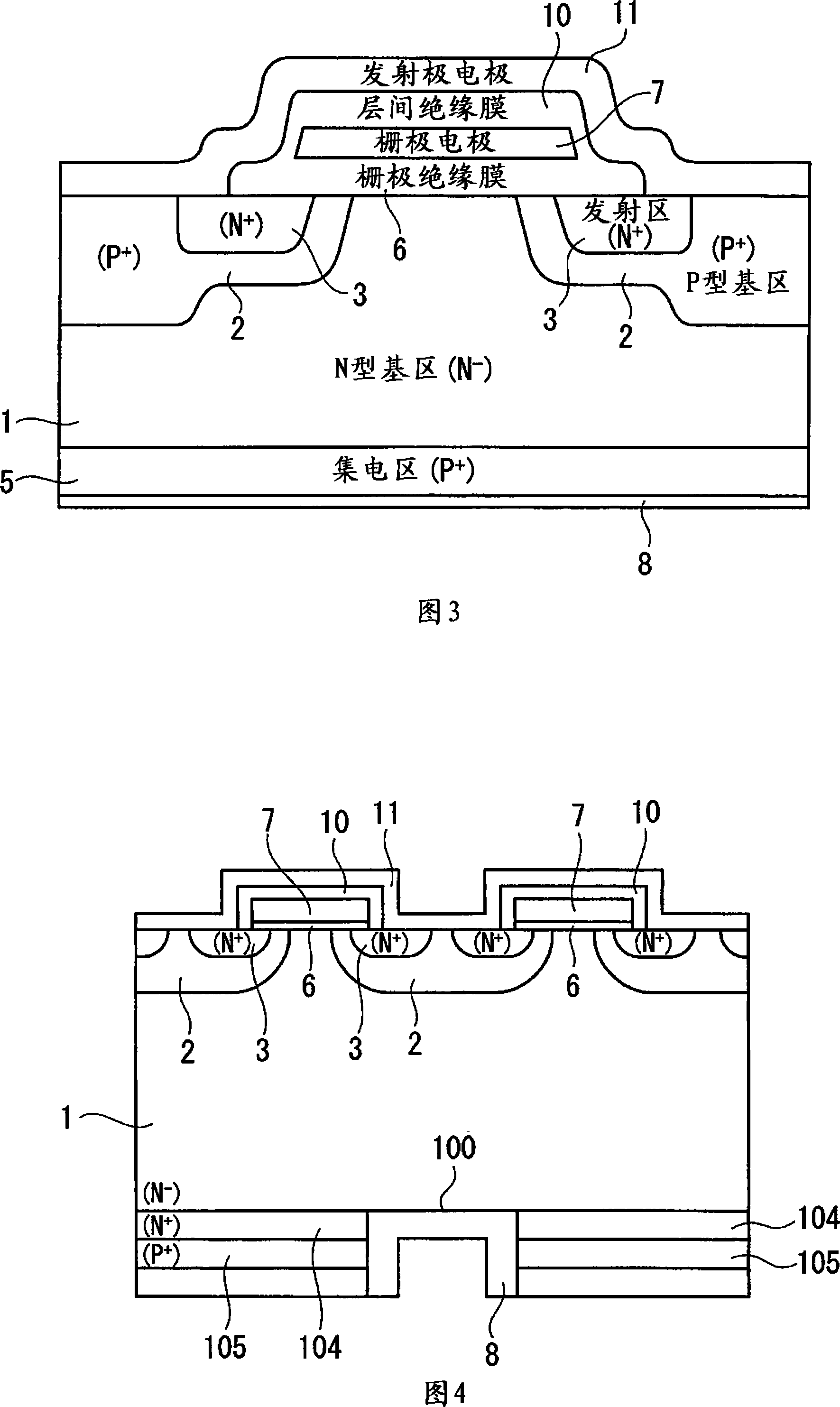

[0078] Based on the drawings, an insulated gate bipolar transistor according to a second embodiment of the present invention will be described. 2 is a conceptual diagram showing the cross-sectional structure of an insulated gate bipolar transistor according to a second embodiment of the present invention.

[0079] As shown in FIG. 2, the insulated gate bipolar transistor has a trench gate structure formed in the trench, and the buffer area 4 is sandwiched between the periodically formed collector region 5 and the N-type base as one of the characteristics of the present invention. The structure formed between the zones 1 is the same as that of the first embodiment, the same symbols are assigned to the same structures, and the description is omitted.

[0080] As in the first embodiment, the N-type base region 1 is an N-type semiconductor region (first conductivity type semiconductor region) in which N-type impurities are diffused.

[0081] The P-type base region 2A is a P-type semic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com