Production process of high-purity plunger piston

A production method and high-precision technology, which is applied in the production of plungers and the field of hydraulic plunger pumps, can solve the problems of matching and matching, equipment jamming, leakage, etc., and achieve the effect of high spherical precision and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention relates to a production method of a high-precision plunger. The plunger is made of high-strength alloy steel or bearing steel, the outer circle part and the ball head part of the plunger are turned, and then the turned plunger is infiltrated. Carbon quenching heat treatment to meet the wear resistance requirements of the parts, and finally the outer circle part and ball head part of the plunger after heat treatment are ground.

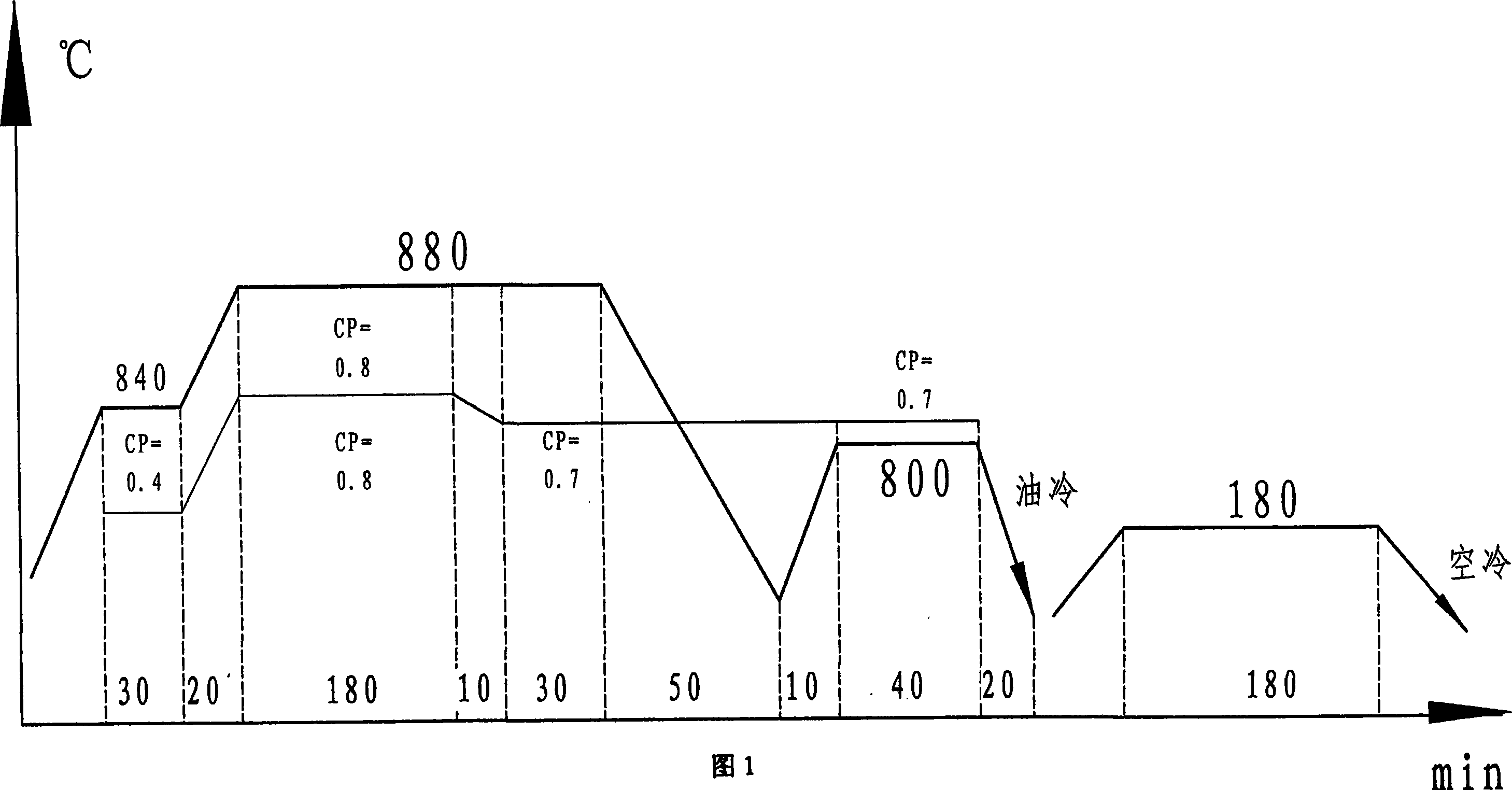

[0022] The specific process parameters of the carburizing and quenching heat treatment are as follows (see Fig. 1):

[0023] 1. Wash the plunger parts in a washing machine and dry for 60 minutes;

[0024] 2. Preheat the dried plunger parts at 350-400°C for 40-50 minutes;

[0025] 3. Put the preheated plunger parts into the carburizing heat treatment furnace, raise the temperature to 840°C, keep the parts at 840°C for 30 minutes, control the carbon potential at CP=0.4, then raise the temperature to 880°C, and raise the carbon poten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com