Acidic silicon dioxide sol and its preparation method and use

A technology of silica and sol, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as pollution, high metal ion content, poor stability of acidic silica gel, etc., and achieve long storage period and low copper ion content , the effect of low copper content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

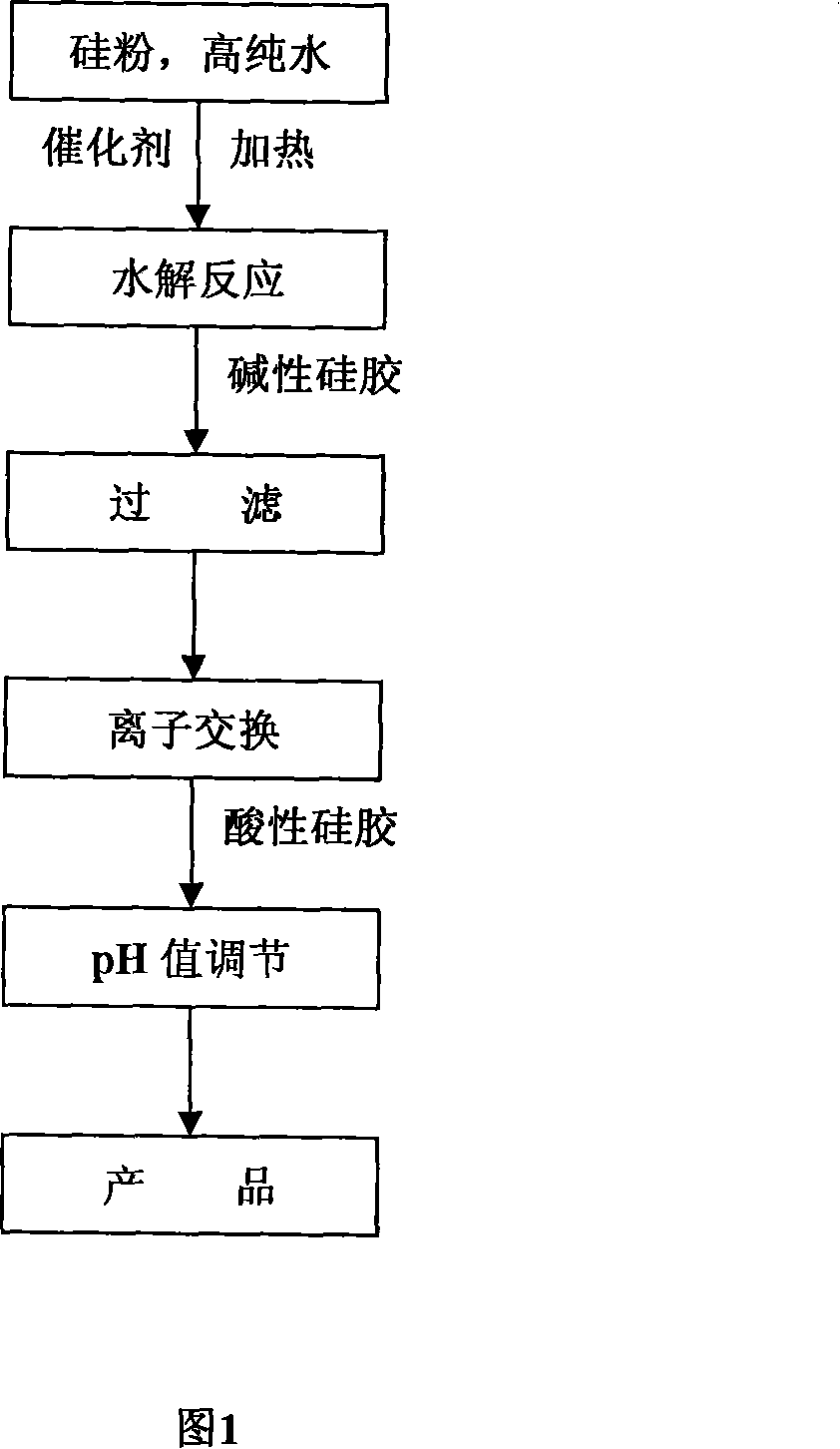

Method used

Image

Examples

Embodiment 1

[0051] Heat 2L of high-purity water in a four-neck flask to 50°C, then add 5.0g of high-grade pure NaOH, continue heating to 70°C, add 30.0g of silicon powder while stirring, and then add 30.0g of silicon powder every half hour, and react for 7 hours Turn off heat. During the entire reaction process, the temperature was maintained at about 85°C. After the reaction solution was cooled to room temperature, it was filtered. Carry out cation exchange to the sol after filtration, the mass ratio of resin and silica gel used is 1: 1, after exchanging 2h, filter out silica gel, carry out regeneration treatment to cationic resin, regeneration solution is dilute hydrochloric acid of 1: 2, after regeneration, use Wash with high-purity water to neutrality, and perform a second exchange. After 4 hours of exchange, filter out the silica gel, and test the parameters of the obtained silica gel. The results are as follows:

[0052] Test items

Embodiment 2

[0054] Heat 500L of high-purity water in the reactor to 50°C by electric heating, then add 2.5Kg of high-grade pure NaOH, continue heating to 60°C, add 2Kg of silicon powder, start stirring, turn off heating, add 2Kg of silicon powder at 75°C After that, add 4.0Kg of silicon powder every half hour, stop feeding after 6 hours of reaction, and continue to react for 4 hours. During the reaction process, high-purity water should be replenished regularly to keep the temperature below 95°C. After the reaction solution was cooled to room temperature, it was filtered. Perform cation exchange on the filtered sol. After 4 hours of exchange, filter out the silica gel, and regenerate the cationic resin. After regeneration, wash it with high-purity water to neutrality, and perform a second exchange. Dilute hydrochloric acid is used to adjust the pH value, and each parameter is tested, and the results are as follows:

[0055] Test items

Embodiment 3

[0057] Heat 500L of high-purity water in the reactor to 60°C by electric heating, then add 2Kg of high-grade pure NaOH, continue heating to 70°C, add 2Kg of silicon powder, start stirring, turn off heating, add 2Kg of silicon powder at 75°C, and then Add 2.5Kg of silicon powder every half hour, stop feeding after 10 hours of reaction, and continue to react for 2 hours. After the reaction solution was cooled to room temperature, it was filtered. Perform cation exchange on the filtered sol. After 4 hours of exchange, filter out the silica gel, and regenerate the cationic resin. After regeneration, wash it with high-purity water to neutrality, and perform a second exchange. Adjust the pH value with dilute hydrochloric acid, test each parameter and use the silica gel to polish the GaAS wafer. The results are as follows:

[0058] Test items

Test Results

testing method

pH value

concentration

kinematic viscosity

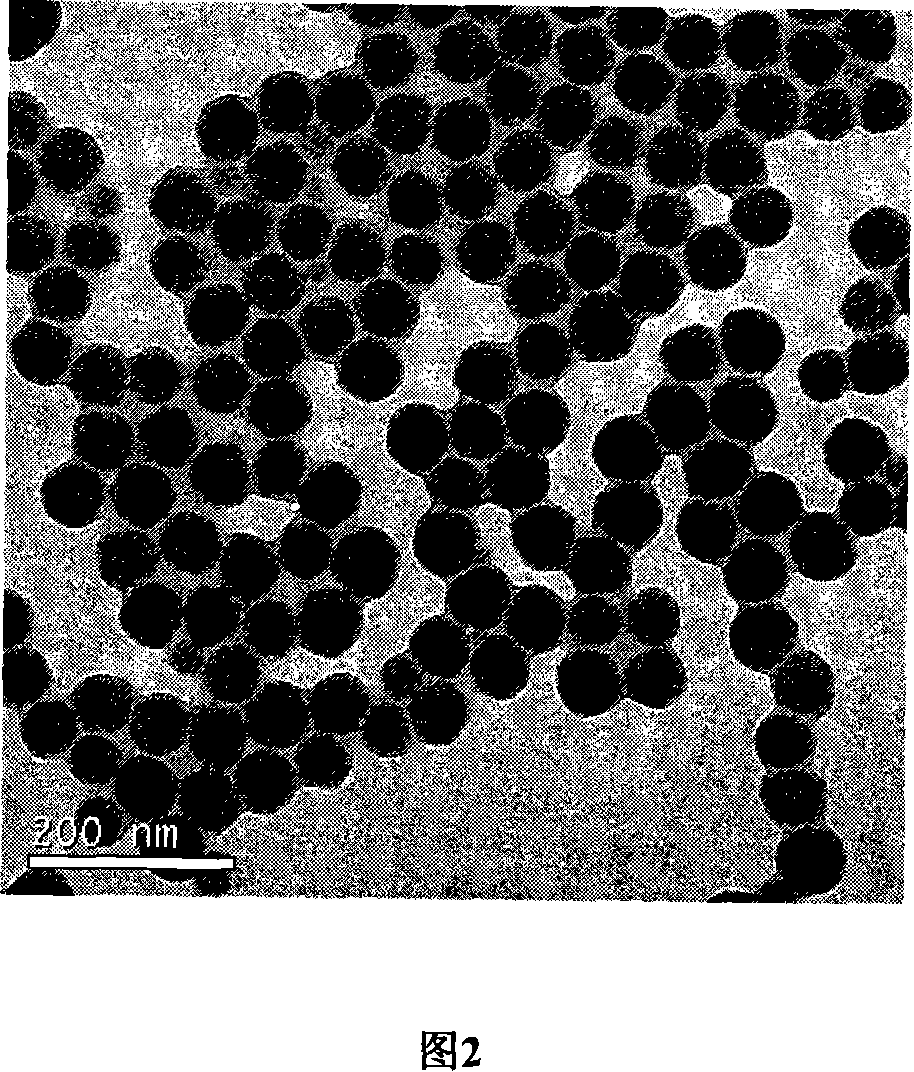

particle size

Copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com