Long extended single-arm boring machine

A cantilever, single-arm technology, which is applied in the direction of boring machine/drilling machine parts, boring bars, boring heads, etc., can solve problems affecting processing performance and structural defects, and achieve high processing accuracy, low cost, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

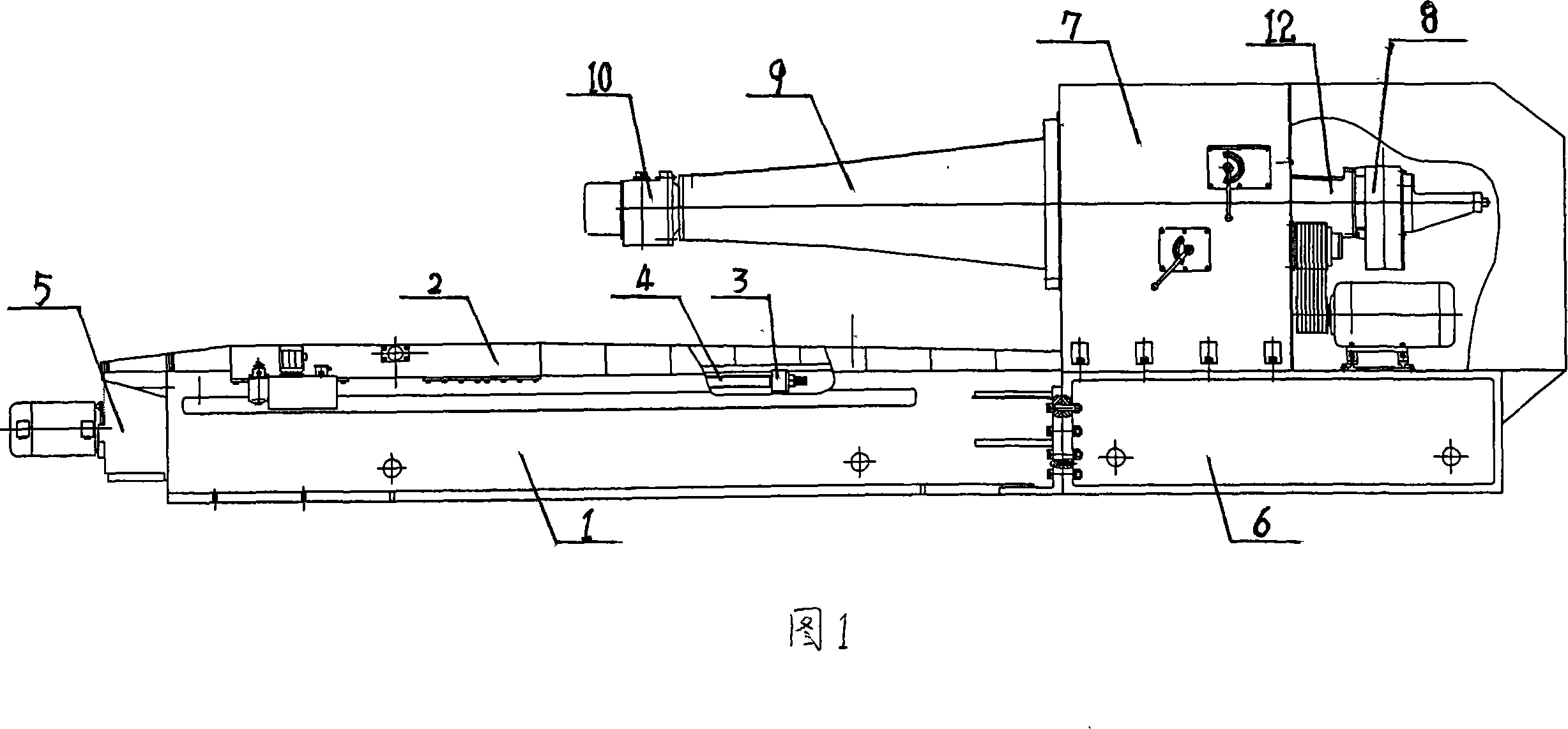

[0034] The long overhanging single-arm boring machine, as shown in Figure 1, includes a bed 1 and a worktable 2 that can slide along the bed. Feed the long screw 4, the tail end of the bed 1 is provided with a longitudinal feed mechanism 5, the output shaft of the longitudinal feed mechanism is connected to the long longitudinal feed screw 4, the front end of the bed 1 is connected to the base 6 with an internal oil tank, The gearbox 7 is fixed on the base 6, the radial feed mechanism 8 is arranged on one side of the gearbox 7, and the cantilever assembly 9 is arranged on the other side, the radial feed mechanism 8 is connected with the cantilever assembly 9, and the front end of the cantilever assembly 9 is fixed with a boring head assembly 10;

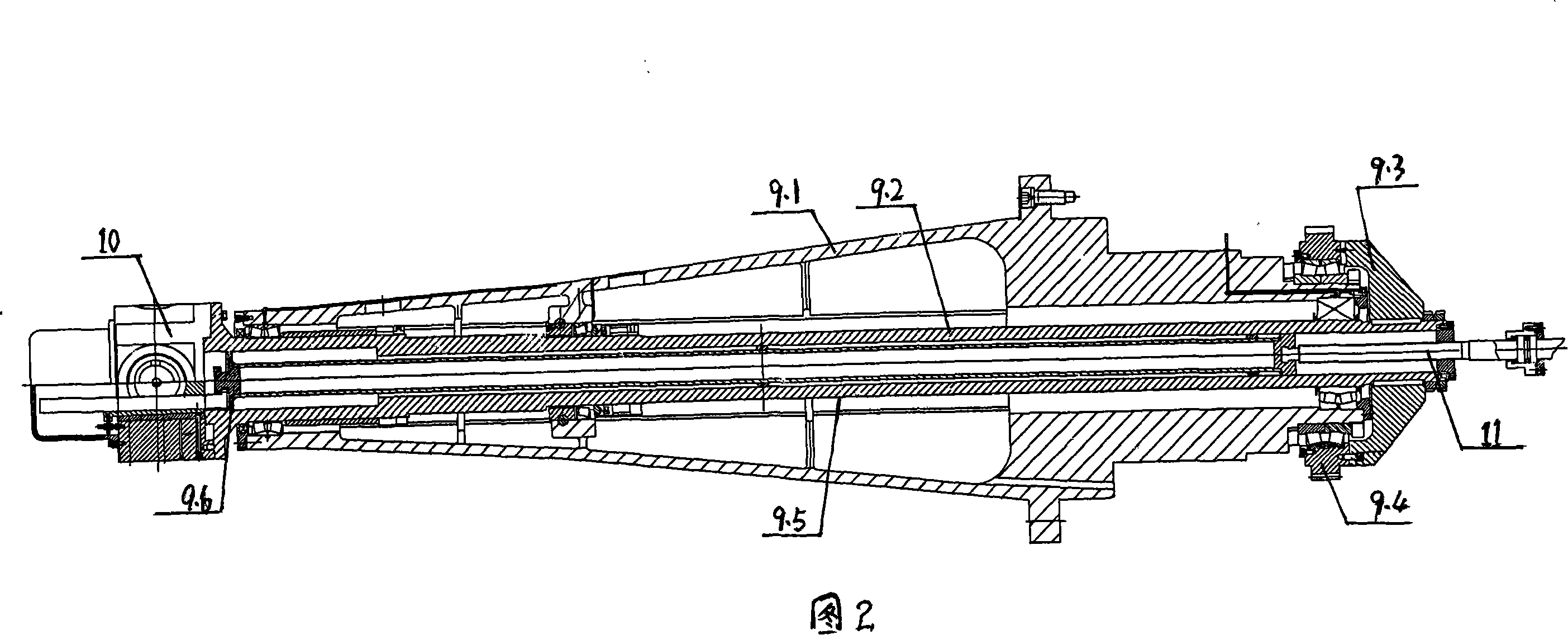

[0035] As shown in Figure 2, the cantilever assembly 9 includes a cantilever housing 9.1 and a main shaft 9.2 supported in the cantilever housing 9.1 through bearings. One end of the cantilever housing 9.1 is provided with a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com