Ammonia absorber with solution cooling down absorption segment and silk screen corrugated filler layer

A technology of wire mesh corrugated packing and solution cooling, which is applied in the field of absorbers to achieve the effect of improving cycle efficiency and facilitating regular cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

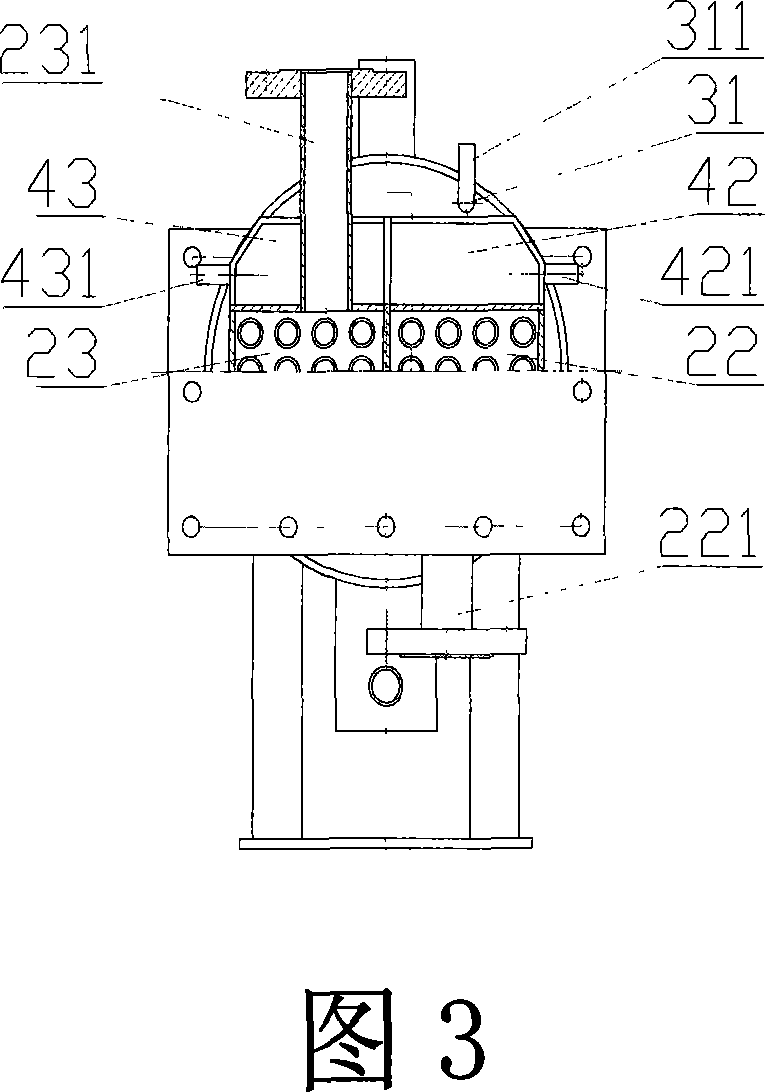

[0013] As shown in Figures 1, 2, and 3, the absorber adopts a horizontal shell-and-tube structure, including a shell 1, a cooling water cooling absorption section assembly 2, and a dilute solution spray distribution pipe assembly 3; The left and right ends of the cylinder body 11 are respectively provided with a left tube plate 12 and a right tube plate 13. The upper part of the casing 1 is provided with an ammonia gas inlet 111; The cooling water cooling absorption section assembly 2 includes a lower heat transfer tube bundle 21, a lower tube bundle inlet chamber 22, a lower tube bundle outlet chamber 23 and a lower tube bundle turn-back chamber 24; the two ends of each heat transfer tube of the lower heat transfer tube bundle 21 are inserted into the And welded in the tube holes of the left tube plate 12 and the right tube plate 13, the lower tube bundle inlet chamber 22 and the lower tube bundle outlet chamber 23 are arranged left and right on the right tube plate 13, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com